Mecmesin solutions for the medical device sector.

Medical device manufacturers operate in one of the world’s most competitive and highly-regulated industries, where patient safety is critical.

Product reliability and lives hinge on compliance to standards, time-to-market and traceability.

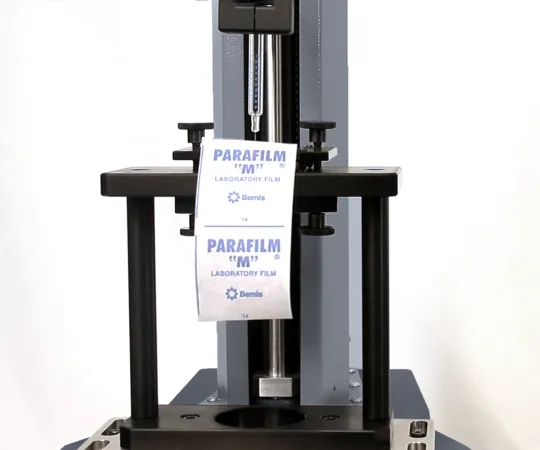

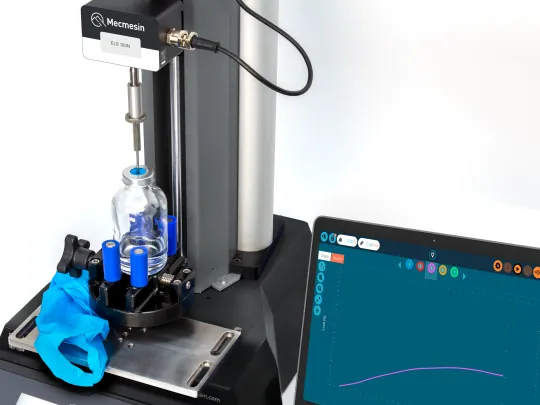

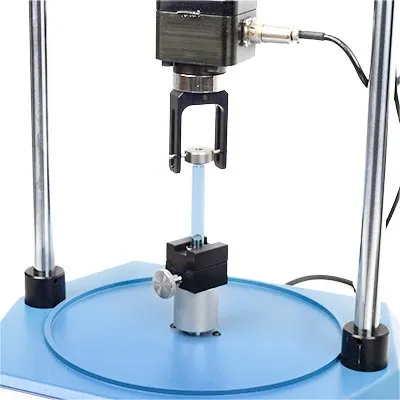

Mecmesin force & torque test systems are ideal for testing the physical strength of all kinds of medical devices. Our test software ensures traceable results with full storage of raw data, a robust audit trail, full operator security and guaranteed repeatability.

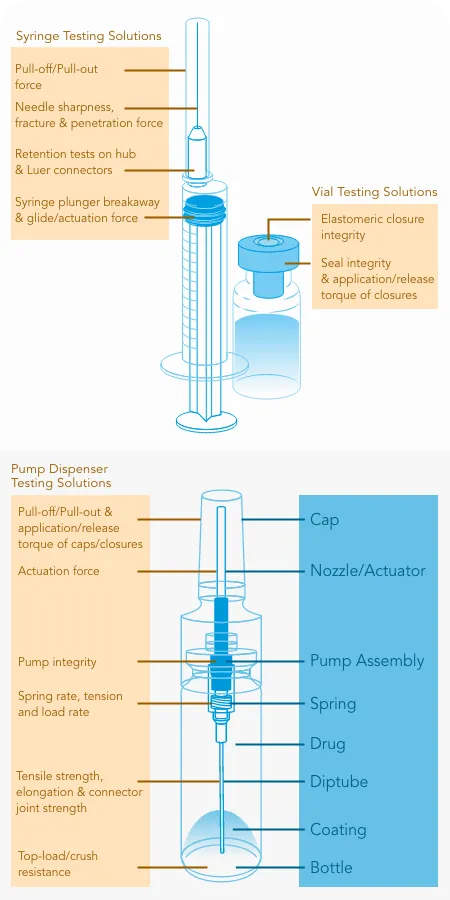

Whether it is testing the torque integrity of Luer connectors, the glide force of syringes, the physical strength of drug delivery devices, prosthetic joints & bone screws; Mecmesin testers provide you with an easy-to-use and affordable solution.

Test to ASTM, BS EN, ISO, DIN, CEN, Ph. Eur. and USP standards

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Face mask strength testing

Syringe plunger breakaway and glide force

Medical sharps bin puncture resistance

Hygienic disposal bin closure testing

Glass syringe Luer lock attachment pull-off

Catheter cap removal torque

Syringe tube pull-off testing

Syringe Luer lock attachment removal

Surgical instrument operational torque

Luer lock fastening and release torque

Inline respiratory filter pull test

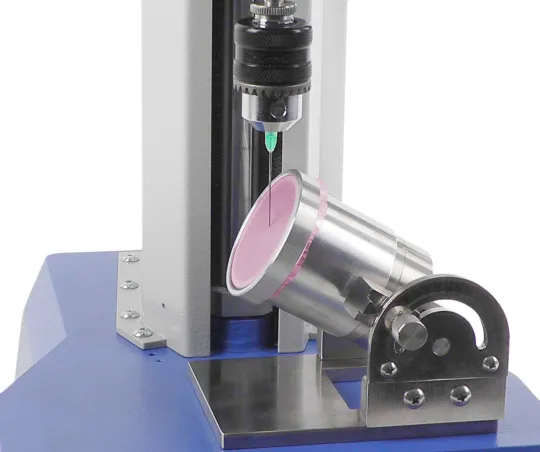

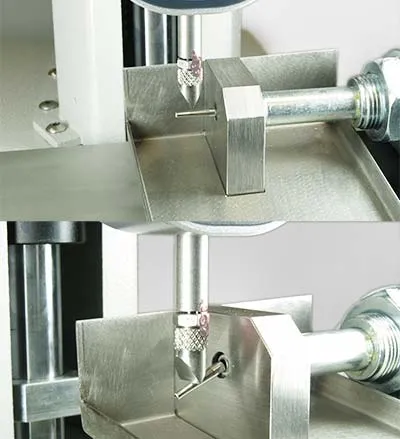

Hypodermic needle sharpness testing

Adjustable spectacles torque test

Luer and small-bore connector torque testing

Dental abrasive disk integrity

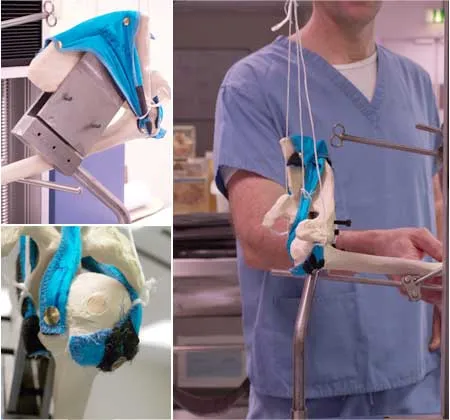

Medical suture device calibration system

Pen injector training aid testing

Peel testing Ostomy bags

Respiratory device spring test

Primate bites force and fracture

Physiological measurement of joint strength

Aluminium cap nozzle flexure break-off force

Cap removal test of plastic vial

Syringe pump calibrator

Medical pouch heat seal joint tensile test

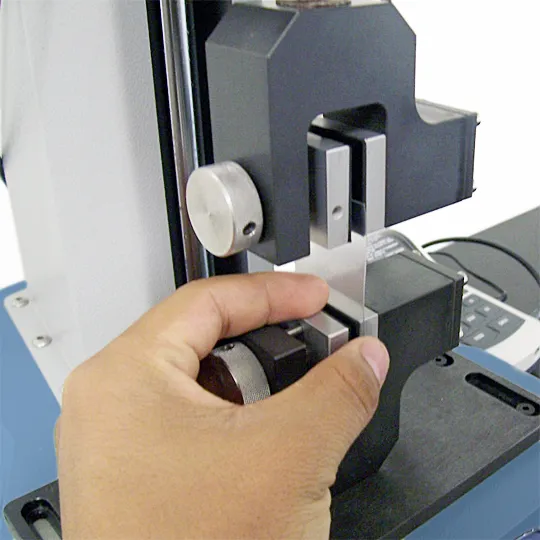

Medical guidewire break strength test

Medical devices testing

Lancet needle retention test

Adjustable spectacles

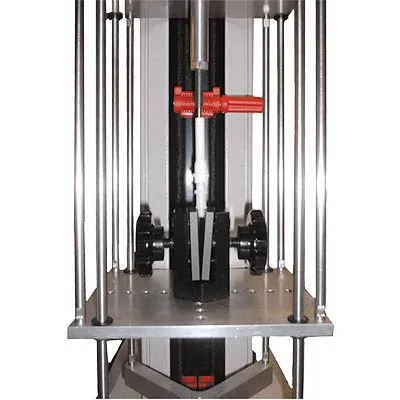

Shoulder prostheses tensile testing

Needle to ferrule pull-out test

Elongation test of infusion solution bag

End float test of inhaler cap

Medical Devices industry brochure

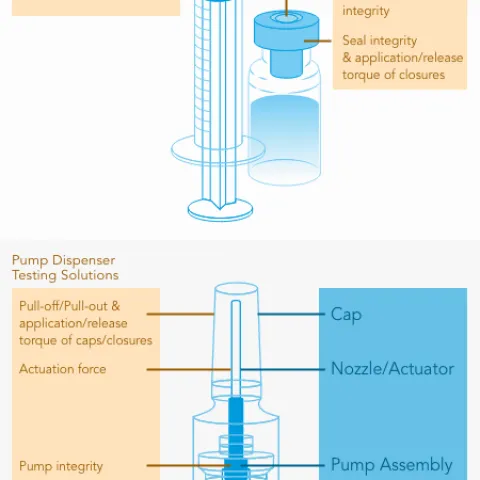

Safety requirements for medical devices and pharmaceuticals are paramount as they are predominantly used on humans. This puts a heavy emphasis on quality control during development, production and packaging.

Download our latest industry brochure for medical device force and torque testing solutions.

![Syringe luer connecter pull-off strength [PDV10032]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1717-PDV10032-web.jpg.webp?itok=AcqJb3d0)

![Medical tube pull-off [PDV14004]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1669-PDV14004-med-tube-pull-web.jpg.webp?itok=roDJsAsL)

![Hypodermic needle sharpness [PDV12122]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1738-PDV12122-A-web.jpg.webp?itok=63Yf3s_H)

![Semi-rigid peel grips [PDV13194] Semi-rigid peel grips [PDV13194]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1671-vacuum-peel-system-web.jpg.webp?itok=6ukLBDXB)

![Biopsy gun spring strength [PDV10011]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/biopsy-pen-fitment-to-trigger-fixture-omnitest.png.webp?itok=5sbAQnKN)