Science & Technology companies often act as an interface between business and centres of knowledge such as universities, government-funded laboratories, and in some instances corporate laboratories. There is an ever-increasing demand to help commercialise innovative ideas that arise from the research base yet remaining within challenging budgetary constraints.

Combining expertise in invention with problem-solving is a common challenge so choosing the right materials and processes is essential to cost-effective innovation.

A thorough understanding of materials and their properties as they are implemented in new designs and processes can make all the difference in the race to be successful in a globally competitive environment.

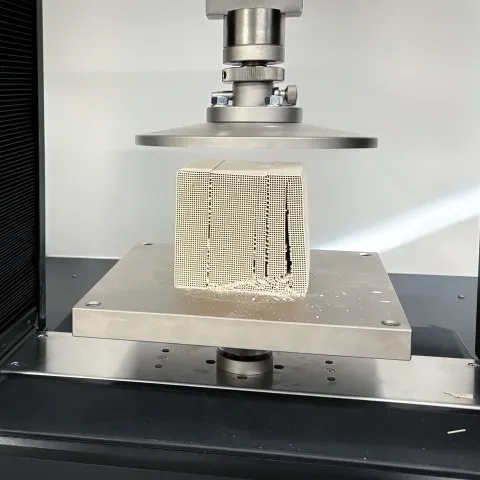

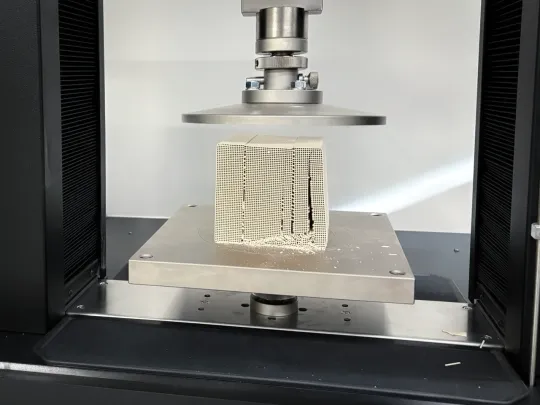

Achieving enhanced performance and proving it is not only possible as a prototype, but also sustainable on a commercial basis, often requires the product to be tested for its mechanical stress-strain, tensile, toughness and fracture characteristics, in areas as diverse as:

- Bio-medical Engineering

- Automotive Technology

- Nano Technology

- Sports Engineering

Mecmesin's force, torque and materials testers are relied upon by science and technology companies across the world.

Whether you are fitting out a new laboratory and need a tester or are you are conducting research on new materials, Mecmesin can help. Take a look at some typical applications of our customers and contact us to see how we can provide you with an affordable testing solution.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Testing rubber to materials standards

Pen injector training aid testing

Primate bites force and fracture

Actuation force of touch screen

Needle to ferrule pull-out test