Concept to consumer

Ensure the quality of your packaging through the supply chain, from evaluating raw and processed materials, components and complete products through to distribution.

PPT Group enables your business to engineer optimised and sustainable packaging solutions. The combined testing expertise from Alluris, James Heal, Lansmont and Mecmesin, delivers solutions for evaluating and assuring product integrity, quality, safety and efficacy.

Explore our specialist packaging testing microsite at PackagingTesters.com

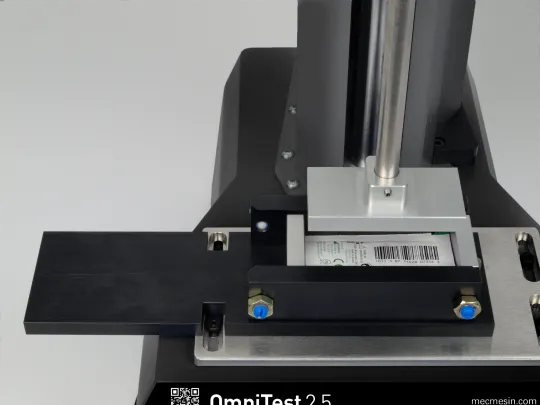

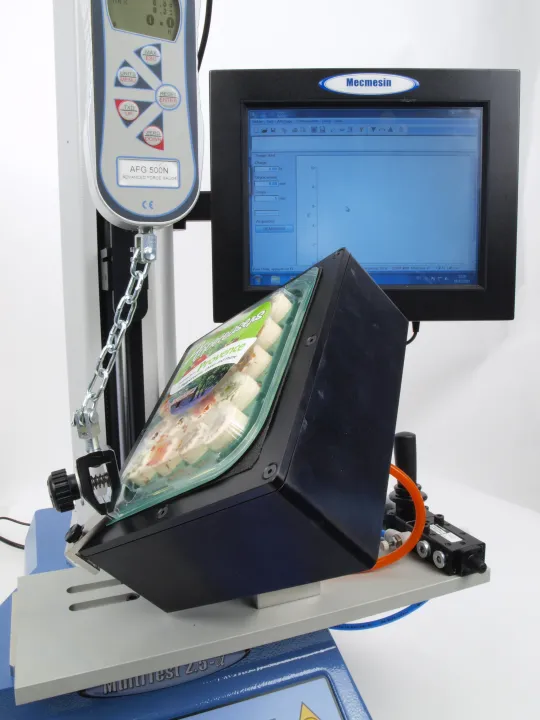

Mecmesin testing solutions for consumer (primary and secondary) and transit (tertiary) packaging.

Consumer packaging

We live in a pre-packed world where the majority of end-user goods are supplied in packaging that protects, but that is designed to be opened easily.

This amount of packaging and the growth in environmental regulation creates pressure to produce it with minimal waste and expense, whilst being fit for purpose.

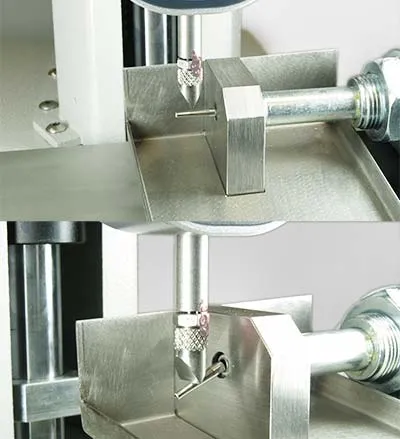

Puncture resistance is combined with pre-tear perforation, security closure with ease of opening.

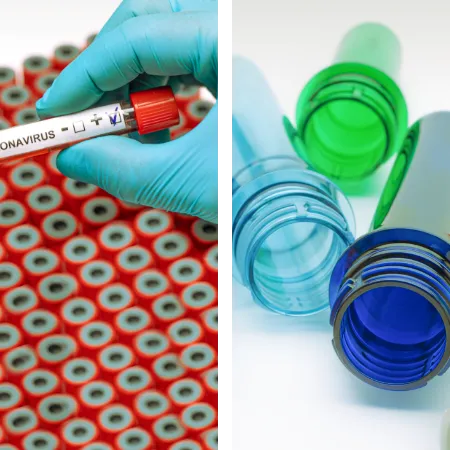

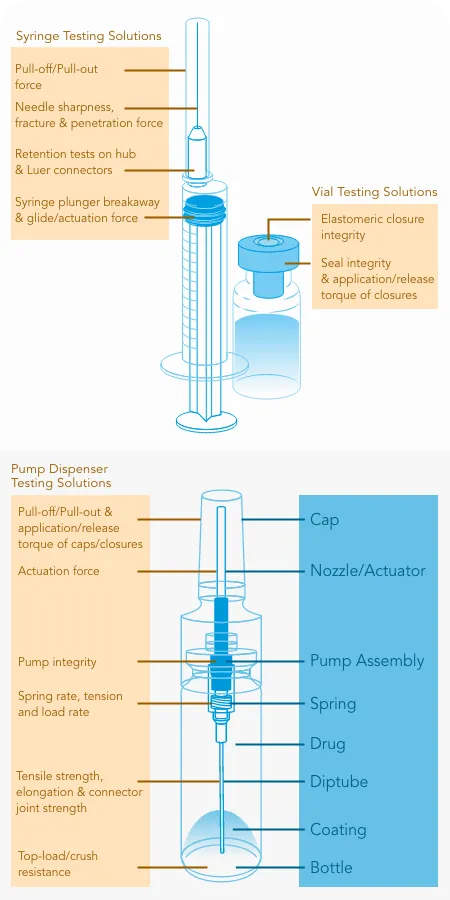

Pharmaceutical packaging is designed for maximum seal and yet minimum peel.

Plastic bottles require thickness to provide strength and stability during the filling, capping and storage processes, but only at the places on the bottle where it is essential. Top-load axial strength testing ensures the bottles can withstand such forces.

Spray cans require the correct finger pressure to actuate the aerosol, and ring-pulls must not break nails or cut fingers when opened. The more packaging becomes aesthetic in itself, the more difficult it can be to grip and test.

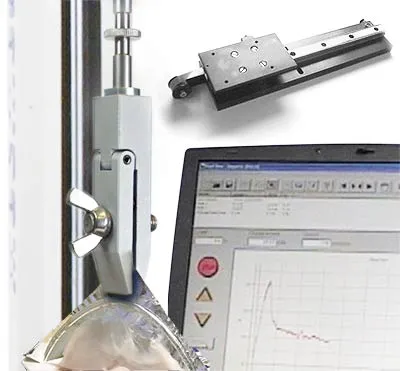

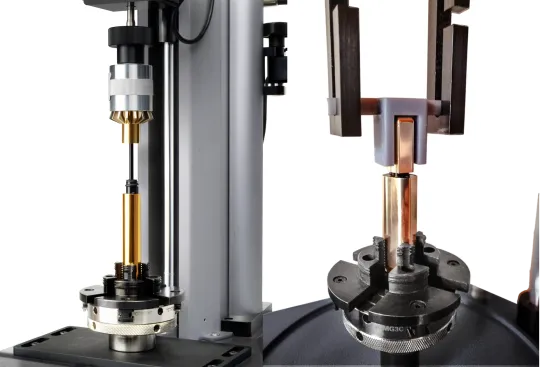

At Mecmesin we design force and torque systems and fixtures for packaging products of all kinds, so that you can apply industry-standard test methods in both designs, and on the production floor for quality control.

Our Emperor control and analysis software is powerful and flexible for reliable, accurate, repeatable testing at the push of a button.

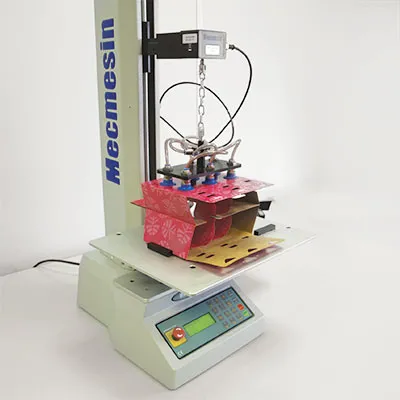

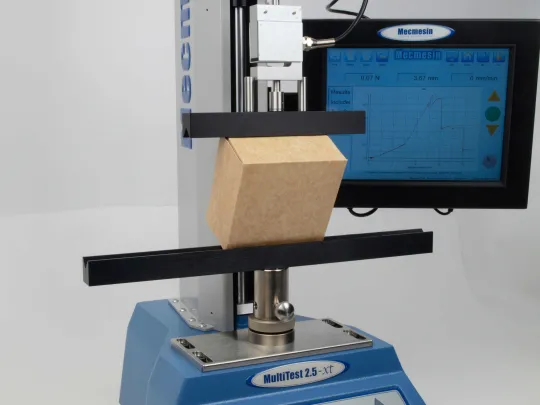

Transit packaging

The target for transit packaging manufacturers is to provide adequate protection at minimum materials cost and weight.

Of the many test types applied, testing board samples is central.

Edge, ring and flat crush can be as predictive of strength as whole-box top-load, and can be achieved using a Mecmesin universal tester.

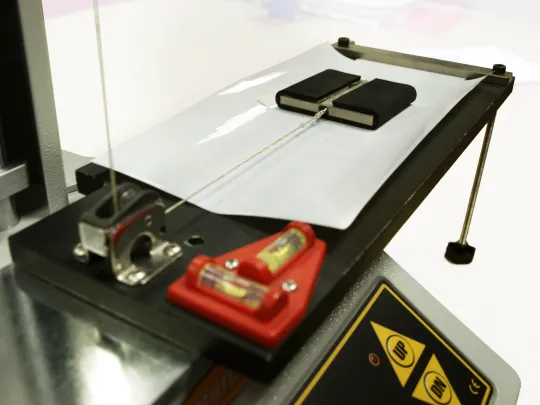

Testing of adhesives, taping and strapping, as well as friction, stiffness, tensile strength and puncture resistance can all be performed using the same machines.

Mecmesin testers provide an ideal solution for meeting corporate test methods and standards from ASTM, BS EN, ISO, DIN, CEN, Afera, FEFCO, FINAT, PSTC, TAPPI, TLMI etc.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Tethered closures testing attachment force

Tamper-Proof Closure Test

Wine can pop-and-tear opening force

Adhesive test on capsulated stoppers

Probiotic drink packaging testing

Lipstick tube force and torque testing

Metal bottle cap on glass pull-off test

Pharmaceutical sachet burst strength

Peel testing vacuum-formed containers

Hygienic disposal bin closure testing

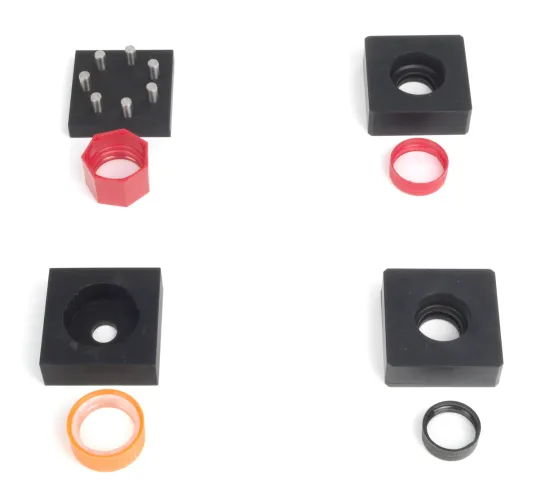

Custom bottle cap mandrels

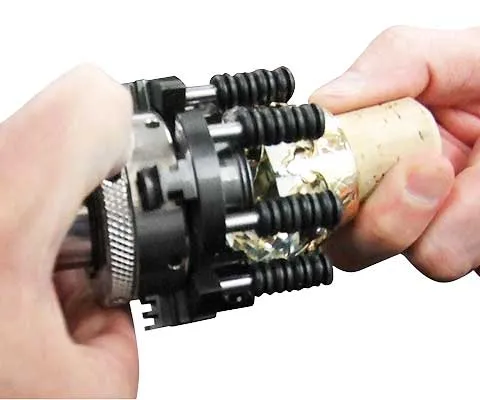

Child resistant closures (CRC) mandrel

Cardboard beverage bottle carrier unfolding

Card and paper crease line testing

Bulk liquid carrier closures

Tea bag integrity

Cosmetics tube flip-cap attachment strength

Cosmetics tin label peel

Split mandrels for closure torque testing

Rotating Vacuum Peel System

ISBT sports cap rotational test

Wine cork extraction test to ISO 9727-5

Fast food tray crush testing

Top-load testing PET bottles

Top-load crush test of plastic bottles

Plastic film tension test

Aluminium cap nozzle flexure break-off force

Cap removal test of plastic vial

Tensile testing on polyethylene film

Tamper evident ring test

Medical pouch heat seal joint tensile test

Glued cardboard packaging integrity

Flip-cap force test

Flexible packaging welded seal strength

DVD removal force test

Actuation force of pump dispenser

Coefficient of friction test on plastic film

Closure torque validation

Seed bottle closure torque testing

Extraction testing of whisky stoppers

Sachet compression test

ISBT sports closure tension test

Torque to twist out a champagne cork

Torque testing beauty product closures

Screw-cap torque test on PET bottles

Screw torque of pump dispensers

![Suction fixture carton fold test, fully open position [PDV8017] Suction fixture carton fold test, fully open position [PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=EFU9vHec)

![Press-fit valve collars [PDV14192]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1650-PDV14192-1-web.jpg.webp?itok=aZByb7MU)

![Flip cap attachment cap disassembly pull-off [PDV13140]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1685-PDV13140-web.jpg.webp?itok=WUckucX6)

![Semi-rigid peel grips [PDV13194] Semi-rigid peel grips [PDV13194]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1671-vacuum-peel-system-web.jpg.webp?itok=6ukLBDXB)

![Split mandrel for jar cap [PDV14075] Split mandrel for jar cap [PDV14075]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1761-PDV14075-web.jpg.webp?itok=-kBwMosn)