Syringe testing to ISO 11040-4 Annex C1 flange break resistance

Solution

- MultiTest 2.5-i software-controlled compression tester

- Special fixtures to locate and load a selection of syringe barrels

Benefits

- Flexible and efficient equipment to repeatedly test to the relevant standards

- Upgradable accessories to extend the test capabilities

Requirement

The ubiquitous medical syringe is an extremely important device, delivering (parenteral) injectable products to the patient by means of a cylinder and plunger mechanism. To ensure safe use of an injectable medication, prefilled syringes for single use were developed to avoid the need to transfer the product from its supplied container into a hypodermic re-fillable syringe—a time-consuming process with potential for contamination.

The medical devices and pharmaceuticals sector is highly regulated, driven by compliance and auditing processes and all syringes need to perform precisely to specification.

One area of mechanical stress within the syringe is at the barrel flange at the back end of the device. To ensure that the flange does not crack or break completely under normal use, or in the process of manufacture or subsequent filling and preparation at the pharmaceutical company, a compression test is performed to measure its break resistance.

Our customer required a test system to meet ISO11040-4 (Glass barrels for injectables and sterilised sub-assembled syringes ready for filling). Annex C covers Test methods for syringe barrels, and C1 specifies Flange break resistance.

Solution

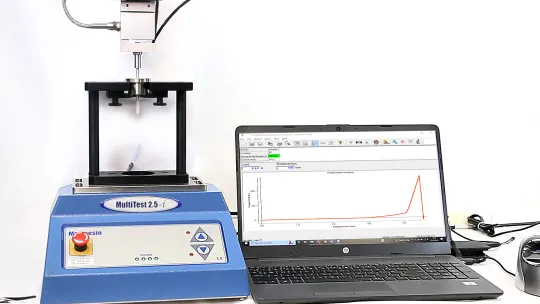

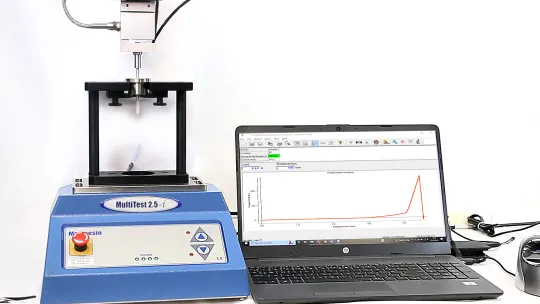

Mecmesin supplied a MultiTest universal tensile and compression testing machine with appropriate loadcell capacity, crosshead speed control and data sampling rate, as indicated by the test standard. The customer provided a selection of syringe specimens, and our Special Applications team manufactured the fixtures to perform the break resistance test; a loading pin and syringe barrel holder. Interchangeable components enabled the customer to test various syringe configurations and also run other tests referenced in the standard.

The software controlled the approach of the compression probe and captured the peak force as the flange broke. An appropriate threshold value was used to immediately indicate a pass or fail result.

Test equipment

- MultiTest 2.5-i software-controlled compression tester

- Special fixtures to locate and load a selection of syringe barrels (PDV22038)

- Additional auxiliary fixtures are available for other Annex procedures to this standard, all fitting the holder frame

![Biopsy gun spring strength [PDV10011]](/sites/default/files/styles/large/public/case-study/2024-04/biopsy-pen-fitment-to-trigger-fixture-omnitest.png.webp?itok=O35PXohl)