Face mask strength testing

Solution

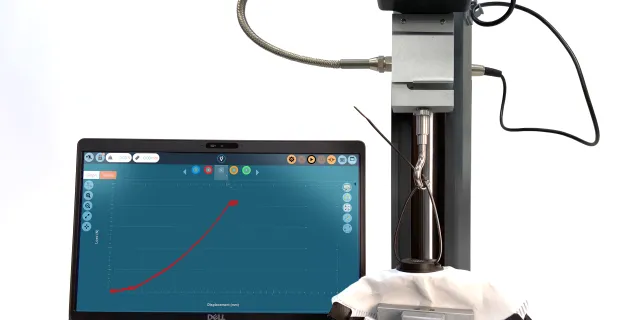

- Motorised or software-controlled tensile/compression test system

- Appropriately-rated loadcell and fixtures matched to mask design

Benefits

- Reliable, accurate and repeatable testing to PPE industry and in-house customer standards

- Interchangeable fixtures and capability to perform tensile and compression tests on the same system

- Consistent output of calculated results and Pass/Fail indication

Requirement

With China now producing over 200 million face masks a day — more than twenty times the amount it made at the start of February – plus other nations diverting manufacturing expertise into face-mask, respirator and other non-invasive ventilation (NIV) support product production, the fight is on to limit the outbreak of COVID-19 coronavirus. The masks include the lightweight ones that people like to wear in the hope of protection against coronavirus as well as the heavy-duty N95 masks used by health-care workers.

Manufacturing masks is not as easy as you might imagine. It involves making the ear loops to secure the mask, the metal strip that lets you bend the mask around the nose bridge, and then sealing them inside sterile packaging.

International test standards exist to make sure the face masks can be verified to protect clinicians and patients from pathogens spread by blood, body fluids and secretions. ASTM F2100 and EN 14683 describe methods to test the Leakage Rate (to evaluate the contact fitness between the mask and the face), Bacterial Filtration Efficiency and Differential Pressure (a yardstick for ease-of-breathing when the mask is worn).

Since the level of efficiency offered by a mask depends on factors such as the filtration efficiency, quality of the material and the fit of the mask on the wearer’s face, the careful selection of mask is important to achieve the desired result. The filtration capacity of mask materials can vary depending on the filter media. The fit of masks varies considerably between those which are held in place by ear loops fastened behind the wearer’s ears to those with tie bands around the head and a nose clamp that can be shaped to the wearer’s nose.

Solution

Mask manufacturers and producers of other Personal Protection Equipment typically also use tensile testers to perform physical strength tests to evaluate material and functionality performance. Made from paper or other non-woven materials masks are subjected to tensile forces until they tear. The connection of the ear-loop straps to the mask is tested to make sure it is strong enough to withstand use without breaking and is complementary to the head harness strength test. Sterile packaging is peel-tested to make sure it can be opened easily whilst still retaining its protective barrier characteristics.

Interchangeable fixtures enable both tensile and compression checks to be performed on all mask materials and components—pull-off and push-out tests plus tear and puncture resistance checks. Software control ensures repeatable and efficient running of routines to international and in-house standards.

Disposable face masks designed for use with manual and automatic resuscitators and ventilators are also subject to physical strength tests. The check valves which limit airflow are tested to measure the torque required to mate effectively with connectors. Mecmesin’s computer-controlled torque testing systems provide the necessary level of precision and control to perform these tests.

Test equipment

- MultiTest test stand, motorised or software-controlled tensile/compression test system

- Appropriately-rated loadcell for expected loads

- Standard fixtures and grips to hold samples and load components