Torque testing CRC closures with a pneumatically-controlled downward force

Solution

- Motorised torque tester with tray for deadweights

- matically-operated lift mechanism for deadweights

- Pneumatic grips for container and closure mandrels

Benefits

- Semi-automation reduces need for operator to manually apply deadweights

- Minimal specimen distortion for optimal results

Requirement

Child-resistant closures (CRCs) come in many designs and are vital for the prevention of harm from toxic chemicals or pharmaceutical products. The type of closure often depends on the packaging and container contents. ASTM D3475: Standard Classification of Child-Resistant Packages defines standard types.

The performance of these closures depends upon several key characteristics:

- Unable to be removed by children below a certain age yet still openable by adults above a certain age, or with dexterity or strength problems.

- A complex-enough mechanism, yet easily understood by an experienced user.

- A security element which is durable for repeated opening and reclosure, and resists opening by destruction.

Testing methods are covered in ASTM D7860: Standard Test Methods for Measurement of Torque Retention for Child Resistant and Non-Child Resistant Packages with Continuous Thread Closures Using Automated Torque Testing Equipment and EN ISO 13127: Packaging. Child resistant packaging. Mechanical test methods for reclosable child resistant packaging systems.

A common CRC design is the simultaneous ‘push down and twist’ cap used on plastic and glass containers. The downward force overcomes the ratcheting safety mechanism, allowing the cap to then be unscrewed by the application of torque.

The difficulty when testing arises from a need to apply sufficient downward force to engage the outer locking lugs of the closure with the inner lugs of the container, without applying excessive force. Any excessive force can cause high friction between the underside of the closure (often against an EPE liner) and the upper surface of the container. This high friction leads to increased ‘twist-off’ torque values when testing.

Solution

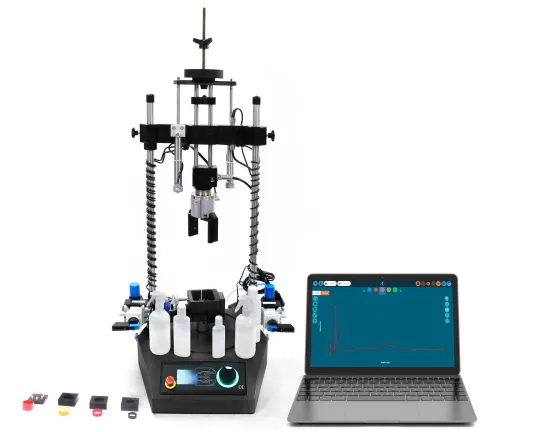

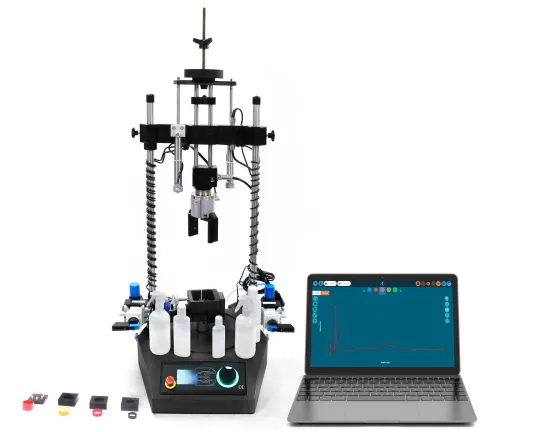

Mecmesin’s Vortex/VortexPro and Helixa/HelixaPro motorised torque test systems feature the ability to apply a stack of deadweights, which act as a constant downward force on the CRC closure. The exact number of deadweights is determined by the manufacturer according to the performance specifications of the closure, bearing in mind the need to prevent excessive friction between closure and container.

The Mecmesin Automated Torque Tester then rotates to perform the torque test as required by the appropriate standard method: press down and turn engagement, push and turn, reverse ratchet.

The torque characteristics can be displayed graphically on Mecmesin software. Alternatively, a simple display can indicate the peak torque values captured during the test.

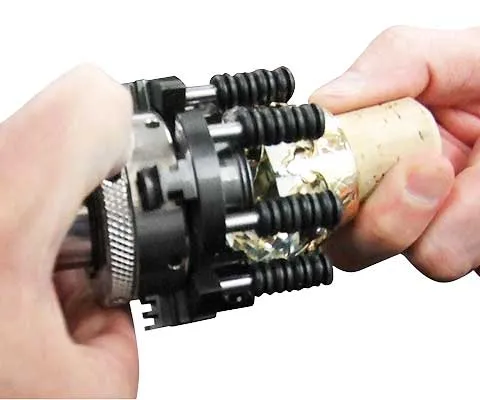

There are no officially published, recommended pass/fail values for CRC release torque, as human panel testing (either adults or children) is deemed to be the indicator of effectiveness of design. However, manufacturers need to be confident in the accuracy and repeatability of their results. The torque test methods within the ISO and ASTM standards recommend taking care that grips and jigs minimise deformation of the closure and the container. Mecmesin’s container holder accessories provide multiple contact points, utilising adjustable soft-foam fingers to securely grip without slipping or deforming plastic containers. Of equal importance is the gripping of the closure itself. Mecmesin designs and provides 3d-printed custom mandrels to match the exact dimensions of the closure. This combination provides the ultimate in reliable gripping for CRC torque testing in the pharmaceuticals industry.

Batch testing for quality control usually requires a minimum of 10 samples per batch to be used. The repeated raising and lowering of the deadweights in each sequence can be an ergonomic issue for operators. Mecmesin’s Special Engineering Department has designed and supplied pneumatic lifting mechanisms adapted and fitted to the torque test stand. This raises the deadweights to allow a new specimen to be inserted into the machine’s grips, and then smoothly lowers the torque head and deadweights onto the closure ready for the next test. Semi-automating the process makes batch testing quicker, more reliable, and less tiring for the operator to perform.

Mecmesin has a full range of torque measurement instruments and motorised systems plus the capability to implement customisation to overcome testing challenges.

Products in the medical and pharmaceuticals sectors require strict regulation in their testing regimes. FDA 21CFR Part 11 compliance is an important factor for manufacturers globally. VectorPro software is available with our Advanced Security Module to extend functionality to meet these demands.

Test equipment

- VortexPro, Vortex, HelixaPro Helixa top-load capable torque testers

- Custom-fit cap mandrels

- Appropriate minimum-deformation container holders

![Split mandrel for jar cap [PDV14075] Split mandrel for jar cap [PDV14075]](/sites/default/files/styles/large/public/case-study/2024-04/1761-PDV14075-web.jpg.webp?itok=DSbMGFLY)