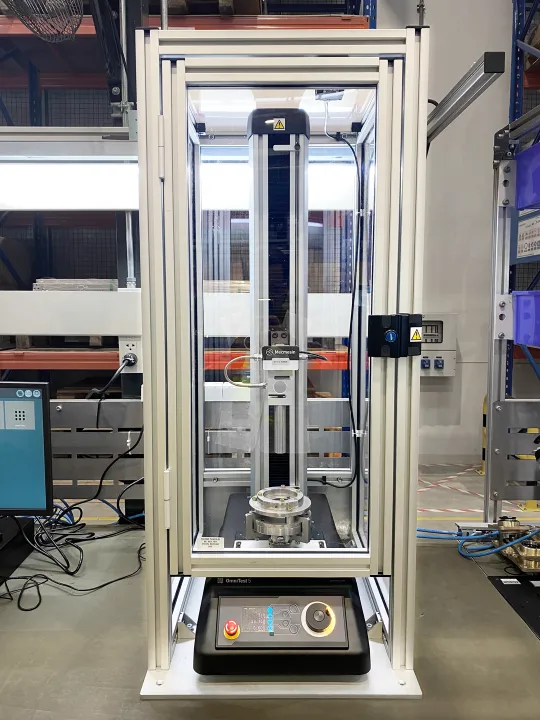

Mecmesin's versatile force, materials, and torque testers are used by manufacturers worldwide to test the quality, strength, performance and safety of electrical, electronic and micro-electronic components and products.

Whether testing the flexure of a PCB, the force to shear-off its components, the torque to actuate a rotary switch or the pressure to trigger a membrane switch, Mecmesin can provide quality-control testing systems to ensure compliance with specification and standards.

Our system control and analysis software not only monitors force/deflection (or torque/angle) but can also detect the very moment when a switching event occurs so that you have a true understanding of the performance of an electronic assembly. Other standard applications include testing the mechanical strength of components, such as the terminal strength of a welded wire-harness, the bond and peel strength of adhered substrates and the compression characteristics of springs.

Whatever your needs in electrical and electronic force or torque, from power transmission down to micro-circuitry, there is a suitable Mecmesin tester.

Test to ASTM, BS EN, ISO, DIN, CEN, IEC, MIL, and more standards-based test methods.

We have over 40 years experience in solving quality control challenges. Take a look at some typical applications of our customers and contact us to see how we can provide you with an affordable testing solution.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Spring testing in the EMS sector

Solenoid force testing

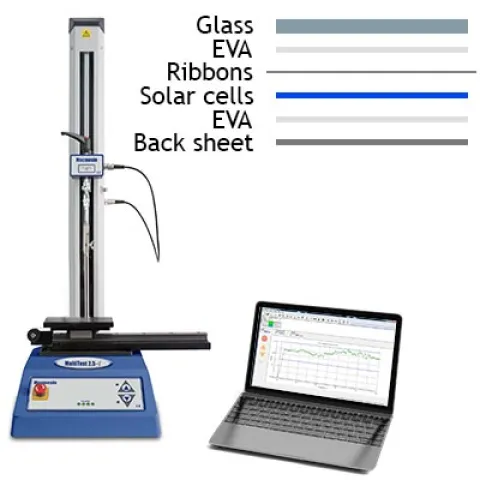

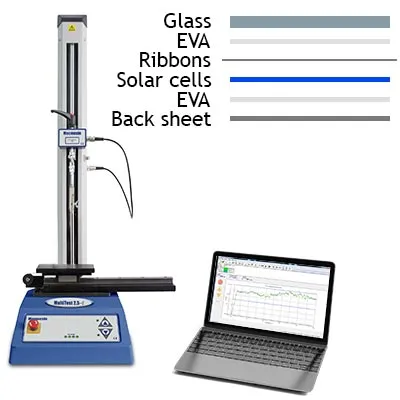

Solar panel peel testing

Electrical assembly component strength

Cable duct strength testing

Insulation film stiffness testing

Cost effective cable strength testing

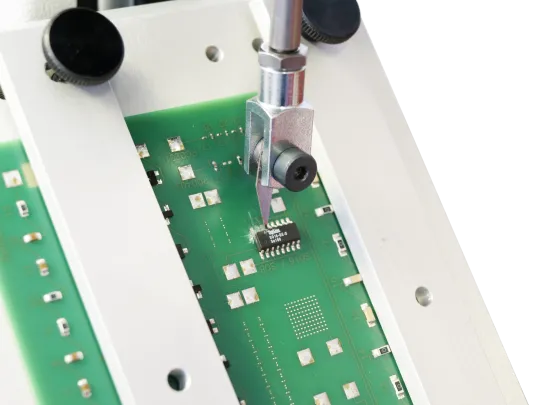

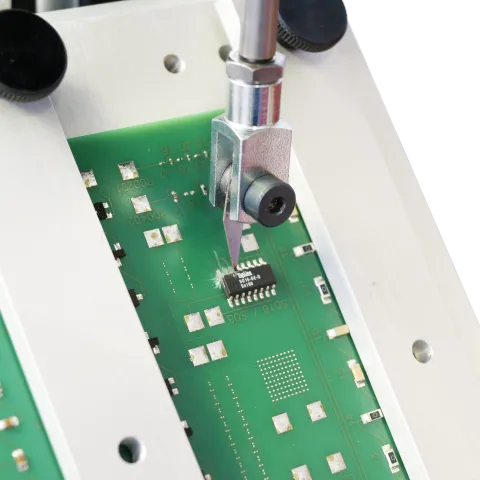

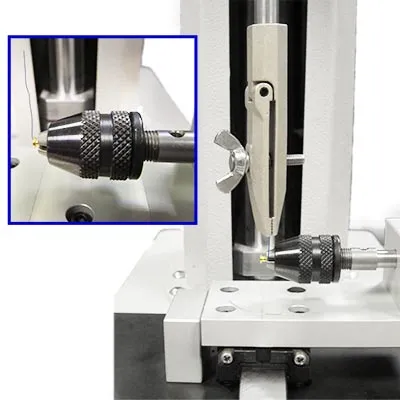

PCB Solder Joint Shear

PCB pull and shear test

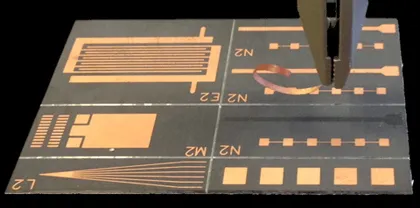

PCB Copper Track 90 Degree Peel

Battery terminal weld integrity tensile test

Lighting weld test

Flat Quick-connect Termination

Electrical harness terminal testing

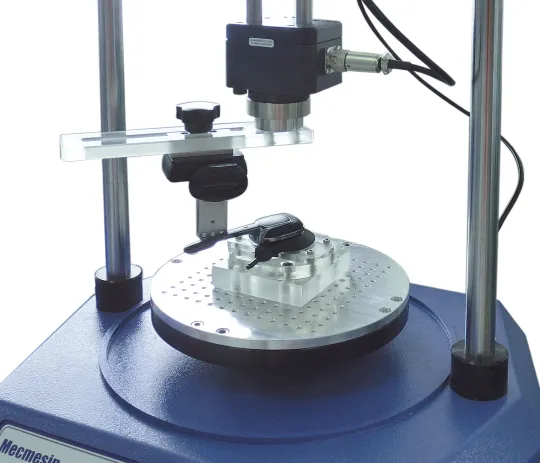

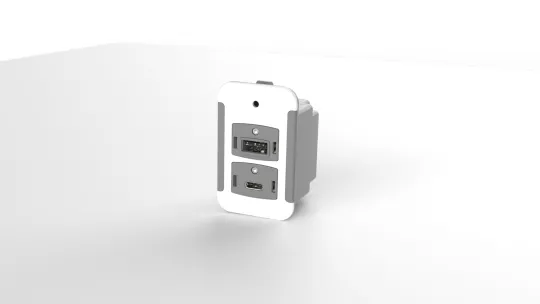

Dashboard button testing

Crimp testing cables

Actuation force of touch screen

Solenoid testing

Soldered flexi-circuits tensile test

Safety critical welds in vehicle airbags

Crimped cable connector pull-off force

![Cable cam grips [PDV12086] for pull test of spliced welded wire](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1702-PDV12086-web.jpg.webp?itok=jiggOPnQ)