Mecmesin has long been providing force and torque testing solutions to suppliers and contractors into the energy industry. Established manufacturers of cross-country and sub-sea oil, water and gas pipes perform compressive and tensile tests on pipes as part of QC checks on coatings. Connectors, valves and manifolds are tested to ensure their mechanical strength is sufficient for harsh conditions. Electrical connectors which utilise soldered or welded terminals need to be tested for their tensile strength.

As the emphasis is turning increasingly to new and sustainable methods of generating or capturing energy, there has been a growing challenge to provide affordable quality-control testing solutions to nascent sectors of the industry.

Solar energy

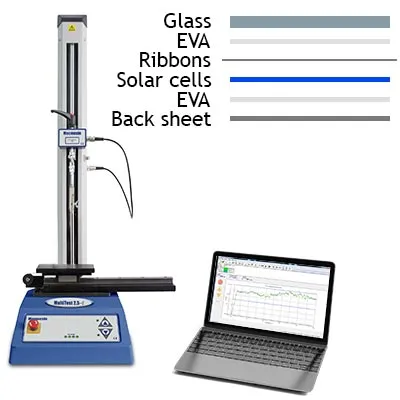

A photovoltaic (PV) solar panel is a sophisticated “sandwich”, made up of different layers of advanced materials. A thin-film (TF) solar cell is made by depositing thin layers of photovoltaic film (eg Tedlar®) on a substrate, such as glass, plastic or metal and these cells are then fitted to rigid or semi-flexible panels. The effective performance of these PV solar panels depends on many factors including their ability to withstand mechanical damage as they are exposed to environmental extremes.

Mechanical strength testing is, therefore, a crucial part of both initial and ongoing quality-control checks for:

- Adhesion strength at initial bonding of EVA to glass, film, or PET - method: 90° or 180° peel test

- Adhesion strength retention after exposure to temperature and humidity extremes, as part of requalifying tests - method: 90° or 180° peel test

- Pull-out strength of MC4 connectors and cables used in the PV junction box

- Assembly strength of the PV module frame to ensure it can withstand load bearing requirements

- Puncture and flexural strength of the glass

Achieve regulatory compliance, test to a range of international standards e.g.ASTM, BS, DIN or in-house specifications.

Our force, materials and torque test equipment offer you versatile, practical solutions to your quality control requirements at an attractive price. We have over 40 years of experience in solving quality-control challenges in the energy industry.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

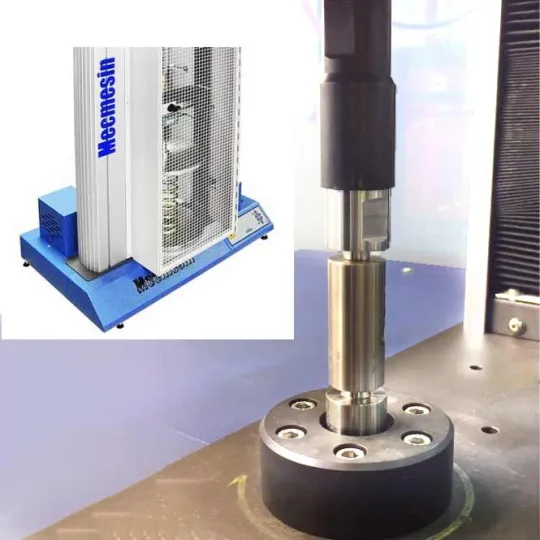

Crush strength testing of catalyst pellets

Testing fluid control valves and seals

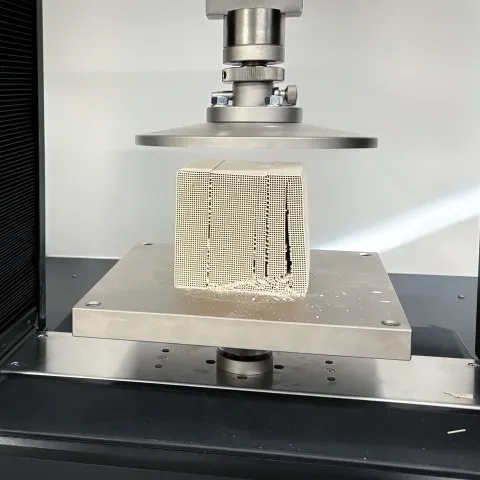

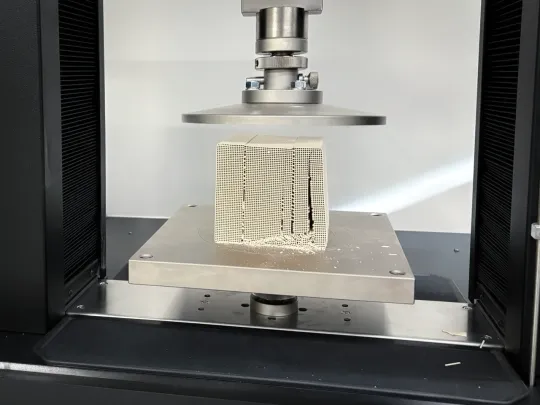

Mineral wool insulation panel testing

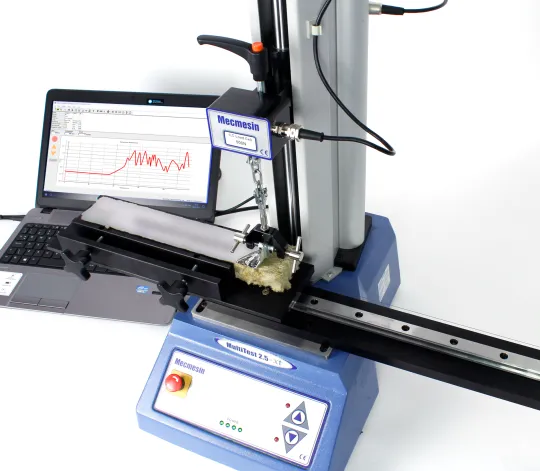

Solar panel peel testing

Alumina sphere crush test