Metals are at the heart of many technologically-advanced industries including aerospace, automotive, electronics and medical not to mention the traditional sectors of construction, energy and machinery. Producers of metal products, components and machinery all face the challenge of testing to ensure that they meet published strength and performance ratings.

Understanding the characteristics of metals before, during and after they are processed is essential for design engineers and process-control professionals. Testing metallic materials until failure by applying static tensile, compressive and shear forces is a quick and practical way of determining their characterisation.

Metals are typically produced in a variety of forms and all use the classic mechanical strength testing methods of tensile, shear, compression and flexural bend to comply with a wide range of ASTM, ISO, EN and industry standards: Strips (hot- and cold-rolled), thin sheets and foils, rods and bars, wires and cables, pipes, castings and forgings, fasteners.

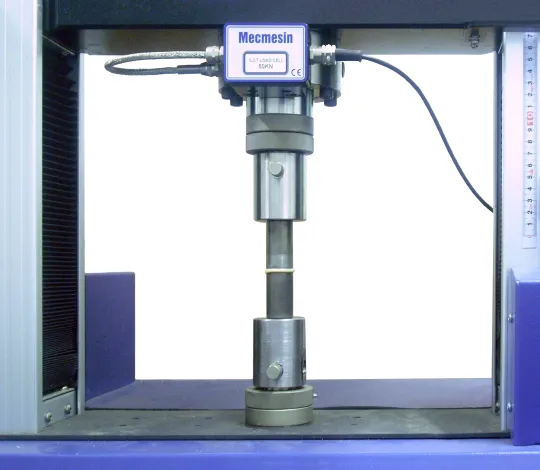

Mecmesin's force, torque and materials testing systems are used in a vast array of applications, a small number of which are:

- tensile strength of:

- copper metal rod

- steel fibre for friction materials (eg brakes)

- galvanised wire

- steel and aluminium pipes

- fabricated metal assemblies

- fasteners

- welded joints

- wiring looms and harnesses

- aluminium composite panels ('Climbing Drum peel test)

- compressive strength of:

- axially-pressed sintered metal products

- compacted metal powders ('Green Strength density test')

- stamped parts ('press-out test')

- stainless steel bolts ('push-out test')

- pipes

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Railcar spring testing

Industrial fixtures and fasteners

Detonator shock tubing

High Performance Plasma Coatings