Insertion and withdrawal cyclic testing of aircraft audio connectors

Solution

- Software-controlled tensile and compression tester

- 500 N loadcell

Benefits

- In-house testing with associated cost savings for the large number and variety of samples

- Multiple systems running the same testing programs to meet increasing production levels

- Cyclic capability to insert and withdraw provides exact end-use replication

The Mecmesin 2.5-i has been of great use to IFPL in the testing of socket-type components and materials

Ben Salmon, Test Technician

IFPL

Requirement

IFPL, based in the Isle of Wight, is a manufacturer of aircraft electronic interface components, bespoke audio and power products, plus turnkey solutions and services for their partners. The company operates in accordance with aerospace quality management systems and other aviation quality standards, also gaining several awards for enterprise and innovation.

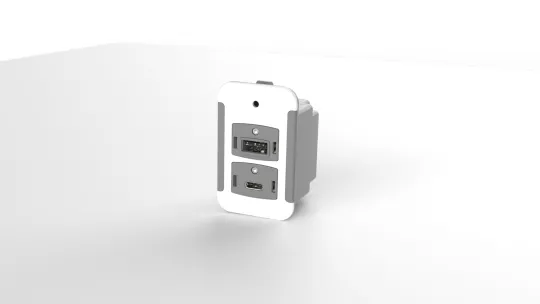

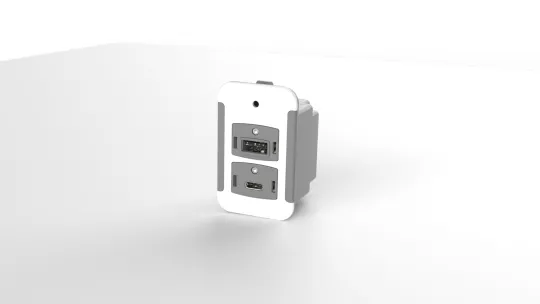

Audio jacks, USB ports, Ethernet ports and other sockets may be housed in the passenger control unit or seat back and each must connect securely to any compatible plugs or connectors on the passengers’ device. Long life, reliability and maintainability are key factors in audio connectors—the passenger relies on the unit to work, even though they may be used thousands of times, and potentially with little care. IFPL requires testing in various applications, and cyclic insertion and removal of the connector to measure plug erosion and degradation in performance is an essential quality control check. This test evaluates the effects of cyclic wear and over-stress in the component.

Solution

Mecmesin supplied a second MultiTest 2.5-i force tester with Emperor software control. IFPL had a requirement to meet increased production and another testing system enabled the company to continue the desired rate of testing.

The MultiTest can perform the cyclic compression and tensile strokes needed to push in and pull out the connector plug to/from the jack. The fundamental test cycles continue as the software looks for a drop in insertion force. If this force falls below a certain programmable tolerance threshold, the run stops, and the sample is graded pass or fail depending on the time duration of the test. This is automatically calculated and indicated in the graphical results.

The ability to perform tests to strict internal standards, has reaped substantial cost efficiencies for IFPL. It adds a further level of qualification to the complete design and development process. The flexibility of customisable procedures that the Emperor software environment allows means that the range of tests may be further extended, and be applied consistently on more than one machine.

Almost every airline passenger needs to charge or listen to their device, or enjoy in-flight entertainment, and components supplied by IFPL are quality-assurance tested to ensure a long life of reliable service.

Test equipment

- MultiTest 2.5-i force tester

- Intelligent loadcell, from 500 N

- Emperorᵀᴹ fully programmable force testing software