Automotive engineering is a complex area incorporating elements of mechanical, electrical, software and safety engineering. Stringent performance and safety-critical criteria must be met to produce successful vehicles.

You might be a supplier of components, sub-assemblies or replacement parts, or an OEM brand manufacturer. In all cases, your reputation depends on compliance with industry standards, internal specifications and customer expectations at every level.

Automotive power-train, chassis, electrical, trim and ancillary sub-systems often require complex test procedures.

Our industry-specific test solutions for automotive sector customers include:

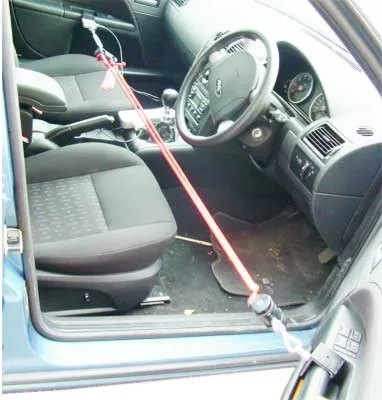

- ergonomic efforts involved in opening, closing and adjusting doors, windows and other architecture

- forces defining the performance of electrical system components

- torque to actuate rotary controls

- forces to actuate dashboard buttons

- compression and tensile properties of springs

- resiliance of flexible plastic and rubber components

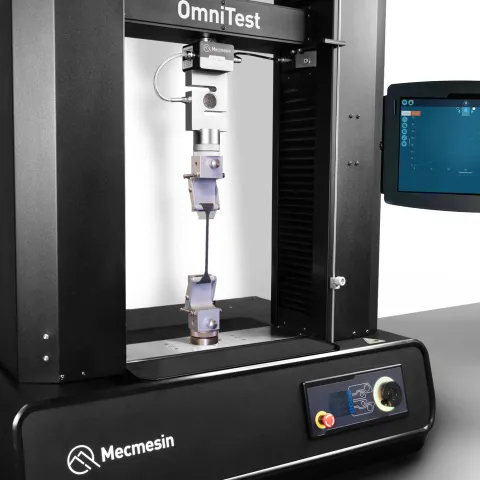

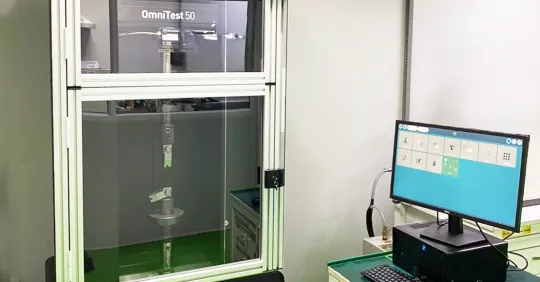

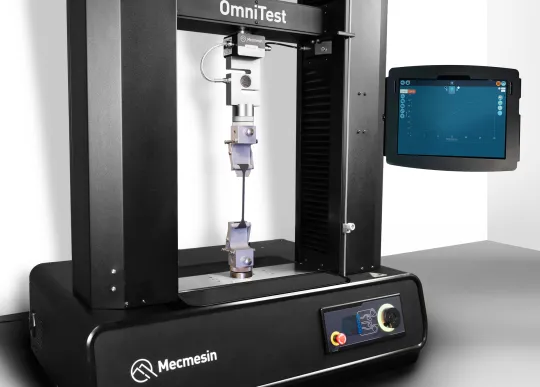

Fast and accurate measurement with reliable force and torque testing equipment, is essential for controlling the mechanical strength and quality of your products, assuring safety and brand perception.

Mecmesin testing solutions are used by leading manufacturers and engineering companies across the world, whether it be at the component, assembly or full build levels.

Test to ASTM, BS EN, ISO, DEF, DIN, CEN, MIL, VDI

We also have a wealth of experience in the more general transport industry sector.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Solenoid force testing

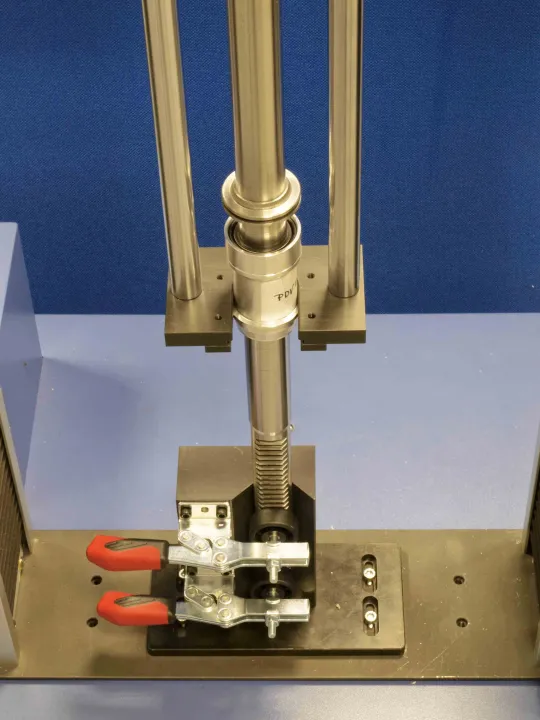

Automotive steering components

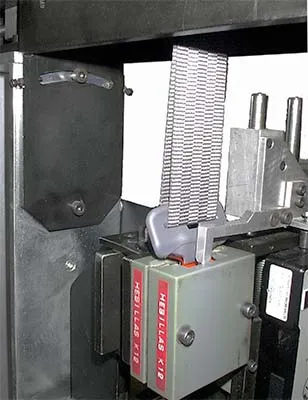

Seat belt locking device test

Motorcycle switchgear actuation forces

Automotive external mirror deformation tests

Battery terminal weld integrity tensile test

Automotive window winder turning effort

Car window sliding force tester

Car door closure effort

Tensile test on rubber gaskets

Industrial fixtures and fasteners

Filter test station

Electrical harness terminal testing

Dashboard button testing

Connection test on fuel injection components