Tensile test on rubber gaskets

Solution

- Software-controlled high-capacity tensile tester

- Selection of fixtures for material tensile characteristics measurement

Benefits

- Testing to international industry standards

- Programmed routines to repeatably perform multiple tests

We use the Mecmesin MultiTest 10-i system to perform regular quality control tests to guarantee the quality of our supplied materials. Mecmesin provided us with a cost-effective solution to our needs and exceptional customer service. I would have no hesitation in recommending them to other companies with materials testing requirements.

Michael Hubbard, Business Quality Manager

British Gaskets Group

Requirement

British Gaskets are a major manufacturer of gaskets, sealing products and mouldings. These are made from a variety of materials to suit a range of applications. British Gaskets required a test system to ensure the rubber and polymer materials Neoprene, Viton, EPDM and Silicone meet their quality control standards and are fit for purpose.

Solution

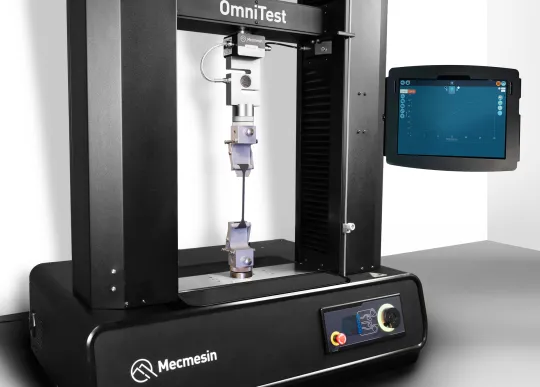

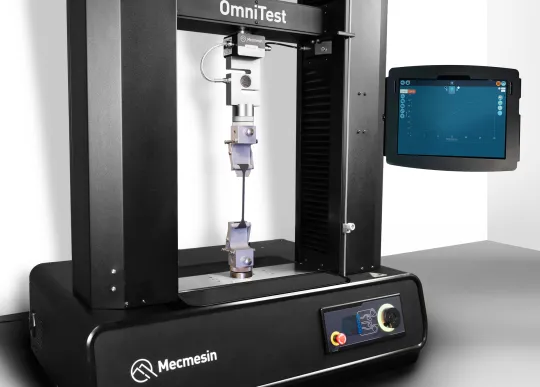

The MultiTest 10-i (OmniTest 10) provides fully automated control of all test parameters and the test results are displayed graphically within the software, showing clearly at what point the material breaks during the test. British Gaskets chose the MultiTest 10-i as a cost-effective alternative to outsourcing their materials testing process.

Twin-column Universal Testing Machines provide enough load capacity for any likely material strength and also allow a generous test space to cope with high strain (elongation) situations.

The software control enables a library of test standard routines to be created and the desired test to be recalled and run by authorised users.

Test equipment

- MultiTest 10-i software-controlled twin-column tensile tester (replaced by OmniTest with VectorPro)

- 1000 N loadcell

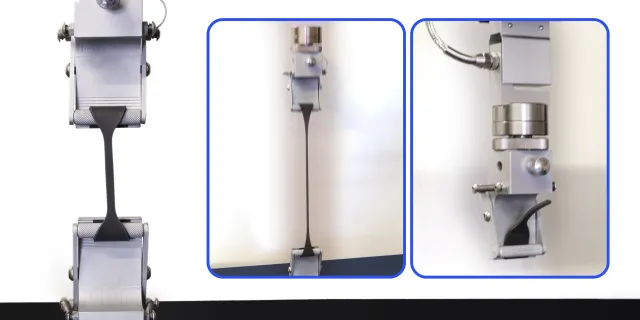

- Spring Loaded Fold Grips and Test Hooks