Our new bench-top universal testing machines (UTMs), including the 5 kN and 7.5 kN single-column models, are designed for precise tensile and compression testing of materials, products, and components. These compact UTMs, powered by the intuitive VectorPro™ software, deliver powerful performance in a small footprint, ideal for labs where space is at a premium. With mid-range load capacities, they offer an economical alternative to larger twin-column testers, making them perfect for diverse testing applications across industries.

Our new bench-top universal testing machines (UTMs), including the 5 kN and 7.5 kN single-column models, are designed for precise tensile and compression testing of materials, products, and components. These compact UTMs, powered by the intuitive VectorPro™ software and touchscreen console, deliver powerful performance in a small footprint, ideal for labs where space is at a premium. With mid-range load capacities, they offer an economical alternative to larger twin-column testers, making them perfect for diverse testing applications across industries.

Our new bench-top universal testing machines (UTMs), including the 5 kN and 7.5 kN single-column models, are designed for precise tensile and compression testing of materials, products, and components. These compact UTMs, powered by the intuitive VectorPro™ software, deliver powerful performance in a small footprint, ideal for labs where space is at a premium. With mid-range load capacities, they offer an economical alternative to larger twin-column testers, making them perfect for diverse testing applications across industries.

Looking for the right testing solution?

Universal testing machines (UTMs) made simple

Our new range of bench-top UTMs, from 0.5 - 50 kN

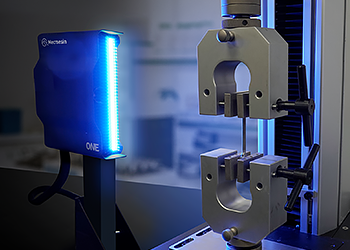

Mecmesin have developed a new range of precision bench-top universal testing machines (UTMs) in single and twin-column formats, for compression and tensile testing from 0.5 to 50 kN loads.

Overview

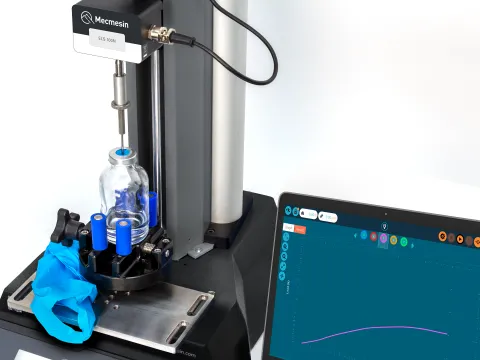

The OmniTest universal tester offers versatility with five load capacities (0.5 kN to 7.5 kN) and an optional touchscreen console (OmniTest Touch).

Designed for ease-of-use, it suits both new and experienced users, making it ideal for various industries.

Controlled by VectorPro test software, it ensures consistency and reliability in testing force/displacement, stress/strain, and speed/load rate. The powerful VectorPro environment allows customization of results criteria and access to built-in calculations, including Young's Modulus, Offset Tield and Ultimate Tensile Strength, catering to diverse applications in manufacturing and R&D.

Test frame

The single-column OmniTest is available in 5 models with load capacities from 0.5 kN to 7.5 kN. They feature a precision ballscrew that drives a moving crosshead fitted with an ELS loadcell. Intuitive controls make the testers easy to use even for novice operators.

The construction of these single-column testers provides the necessary test space and crosshead travel for conducting elongation tests on your specimens up to 1186 mm. They deliver the strength capability for low- and mid-load break tests on a variety of materials and components. All models are ideal for the universal testing of samples to determine their tension, compression, flexure, shear and fracture characteristics.

Upper and lower safety limit switches minimise the risk of accidental damage caused by grips colliding. The 5 kN and 7.5 kN frames also feature a linear slide mechanism with excellent rigidity and strength to measure stiff samples. A protective bellow prevents dust and splintered materials from becoming trapped inside the machine.

For operator safety, a range of protective shields and enclosures is available on all machines, for situations where specimens may shatter or create projectiles upon failure.

Designed to apply tensile and compressive forces from 2 N right up to a capacity of 7.5 kN their high-quality construction, manufactured under ISO 9001 quality standards, ensures the ultimate in repeatable materials testing.

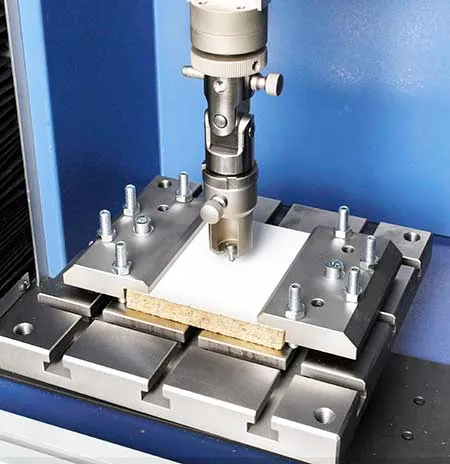

The base plate of the OmniTest is pre-drilled with threaded holes to connect a wide range of grips and fixtures. The OmniTest also uses quick-change (QC) adaptors that speed up the interchange of grips, for example when you need to perform a variety of different tests on different geometries of a material or finished product.

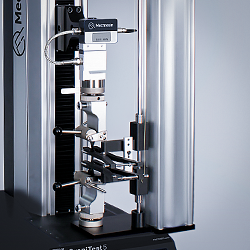

Loadcells

The OmniTest UTMs take advantage of Mecmesin's range of high-resolution Enhanced Load Sensors (ELS) to precisely record tensile and compressive loads.

When seeking to precisely measure forces across a wide range it is often necessary to use multiple loadcells. The dovetailed crosshead design of the OmniTest minimises operator setup and configuration by quickly and easily sliding on a new loadcell, where its calibration characteristics are immediately recognised by the software without any input from the operator.

These interchangeable ELS loadcells are compatible with any OmniTest test frame of equal or higher capacity and are chosen in order to optimise the accuracy of your test results.

Fourteen different sensors, all measuring from zero, are available to cover the range from 2 N up to 7.5 kN. This ensures that you have the optimum selection to meet all your tension and compression testing needs. Measurement accuracy is an outstanding ±0.5% of displayed reading.

Each ELS sensor is delivered as standard with its own calibration certificate traceable to national standards.

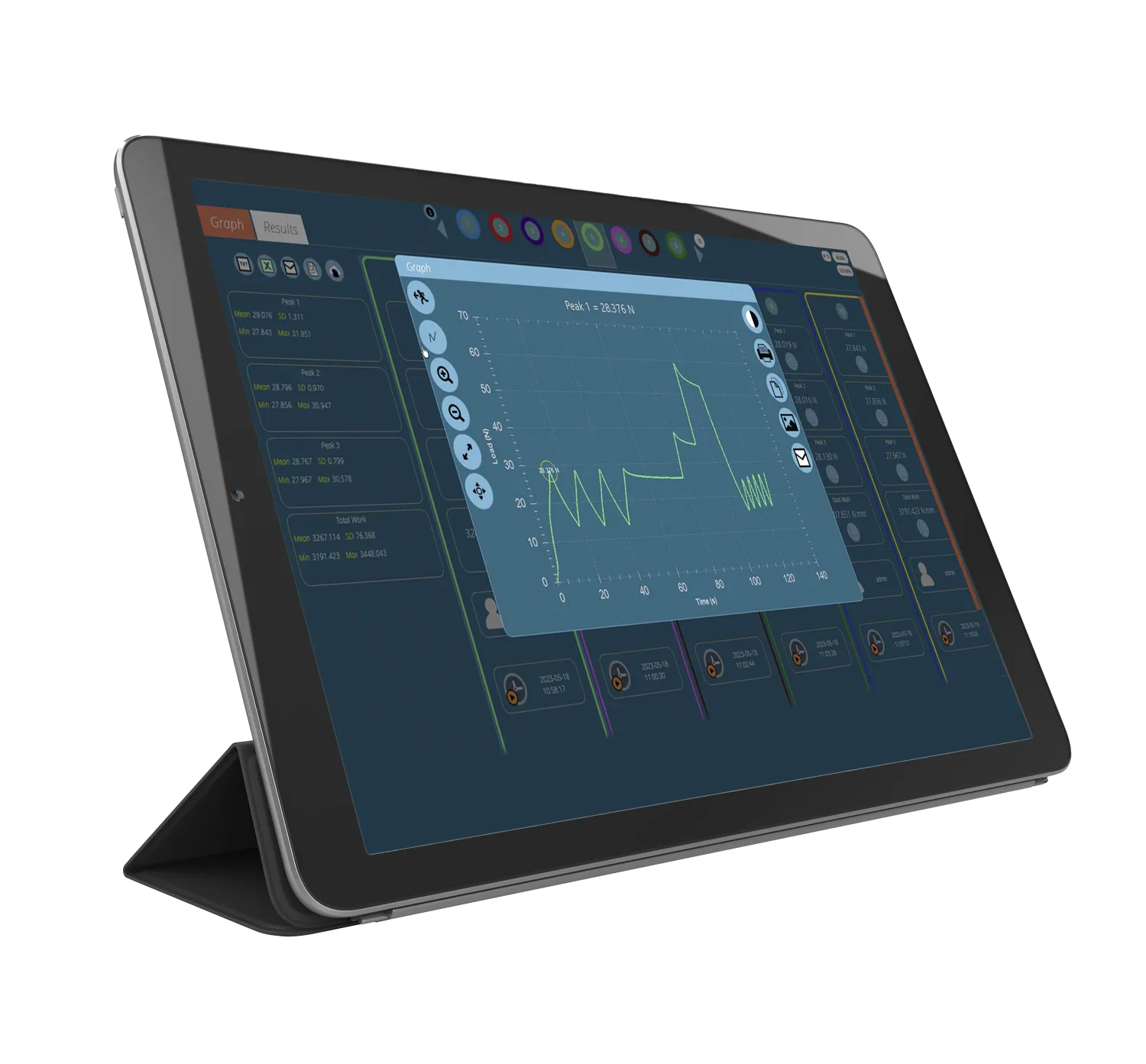

Software

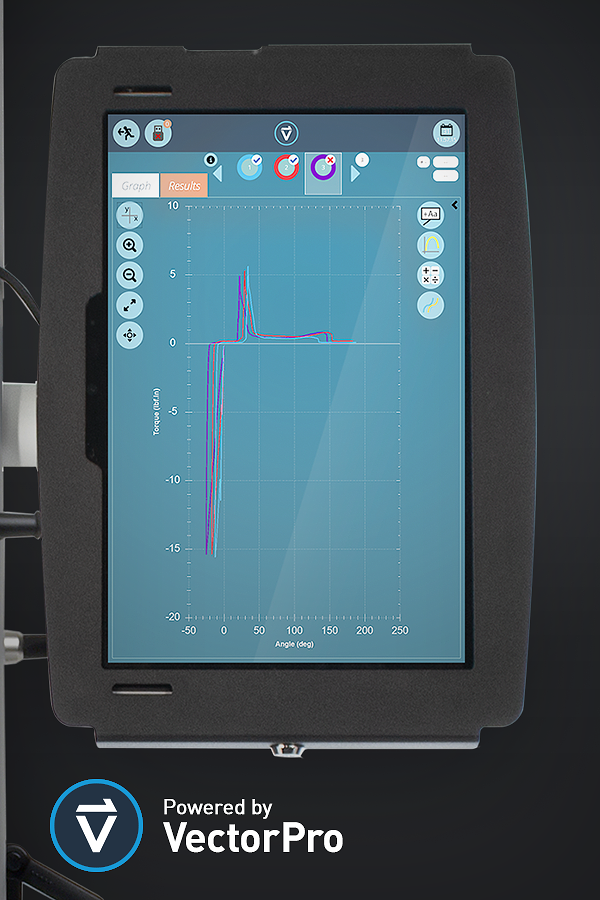

VectorPro testing software is at the heart of the OmniTest universal testers

VectorPro delivers outstanding control of the motor, whilst simultaneously collecting data at 1000 Hz from the ELS loadcell and the displacement encoder of the frame.

The software is intuitive for both operators and managers. Personalised user accounts and a streamlined design mean that the workflow is simple and it is easy to create step-by-step test methods according to the precise requirements of your applications.

Access to the most commonly used test methods enables operators to move seamlessly from task to task, keeping training time to a minimum.

By plotting the data of force/displacement, stress/strain in real-time on a graph the operator can immediately identify exactly how the test sample is performing. Pre-set or custom calculations analyse the data to determine whether the specimen has met the pass/fail criteria. VectorPro includes standard calculations for Young's Modulus, Offset Yield, Ultimate Tensile Strength, Nominal Strain and a whole host of other materials characteristics. For product testing, it is possible to create custom calculations within a few seconds by using the drag-and-drop functions.

At the end of the test, the comprehensive reporting module within VectorPro enables the operator to issue a test report as a PDF. An extensive suite of template reports can be easily tailored to your internal or your customer's exact requirements and be automatically emailed to them as an HTML file. Test data can also be exported to Excel or to the network for further analysis.

VectorPro generates a clear audit trail with electronic-signature functionality - a must for medical and pharmaceutical clients seeking compliance to FDA 21 CFR Part 11.

Grips and fixtures

Standard and customised fixtures to meet your needs

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin has designed a range of tension and compression grips to hold a variety of components. They include wedge grips, vice grips, peel jigs, bend jigs, compression plates and many more.

The base plate of the OmniTest is pre-drilled with threaded holes to connect a wide range of grips and fixtures. The OmniTest also uses quick-change (QC) adaptors that speed up the interchange of grips when you need to perform a variety of different tests.

The varying nature of specimen sizes and shapes often makes it necessary to design and produce a special grip. Mecmesin's team of design engineers can work with you to develop the best grip for your specimen and utilise our 3D printers to produce lightweight, precision fixtures to meet your needs.

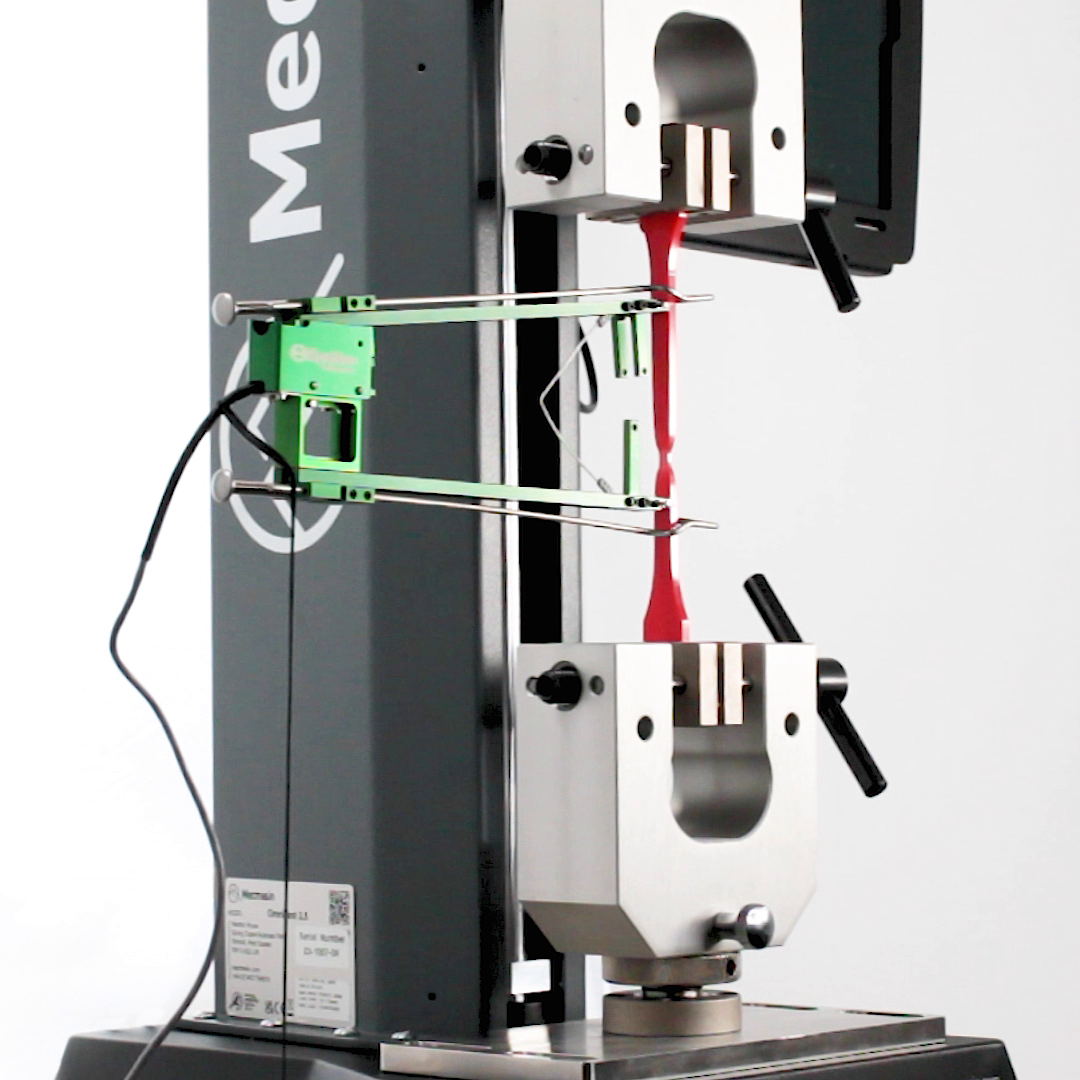

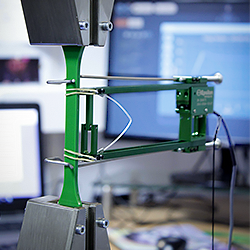

Extensometry

Extension or compressive deformation measurement

When testing the extension or compressive deformation of a specimen it is often acceptable to measure the movement of the loadcell and grips, as defined by the crosshead distance travelled (known as 'grip separation').

This is taken directly from encoders situated on the ballscrews of the OmniTest. VectorPro software compensates for movement encountered within the loadcell and grip string (known also as 'Correction for Machine Compliance') but it cannot be as accurate as measuring extension directly upon the specimen. In some test applications, this is perfectly acceptable and does not impact the relevance of the measured results.

For materials requiring extension measurement to be taken directly on the specimen, a range of contact extensometers is available for use with the OmniTest. The range of contact extensometers include short-travel extensometers suitable for rigid materials (eg hard plastics and metals) through to long-travel extensometers designed for highly elastic materials (eg rubbers or soft plastics), simply select the model which best suits your material's characteristics.

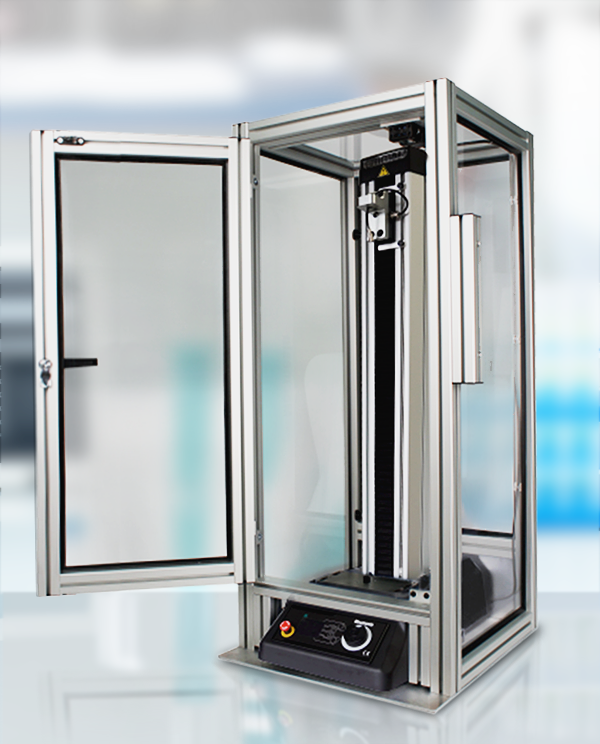

Safety guard

Operator health and safety

Our systems can be supplied with a standard safety guard to prevent access by the operator to the testing area whilst the test is in progress. These have a rigid metal frame with integrated polycarbonate panels to allow the operator to view the test area from outside. Hinged doors are fitted with switch-activated interlock mechanisms that prevent system operation when open.

Guards for single-column test stands are provided on a solid metal platform, with location holes available for securing to a workbench, to ensure complete stability.

Safety guards are supplied with CE marking and a Declaration of Conformity in accordance with several harmonised standards of the Machinery Directive 2006/42/EC, including BS EN ISO 12100:2010, BS EN ISO 14120:2015, BS EN ISO 14119:2013, BS EN ISO 13855:2010, BS EN ISO 13857:2008, BS EN ISO 13849-1:2015.

Please see our Safety Guards datasheet for a complete list.

If the risk assessment for your application indicates protection from egress is also required, our engineers can offer a custom design to meet your needs.

A truly universal tester

Our range of universal testers are developed for versatile testing of materials, components and products.

Elongation at break testing

View test typeCompression testing

View test typeBend/flexure testing

View test typeStress testing

View test typeTop-load testing

View test typePush in testing

View test typeTensile testing

View test typePull off/out testing

View test typeEmperor™ Software

VectorPro® software

VectorPro is our advanced force testing software package developed to perform tensile, shear, bend and compression tests on materials, components and products. Present measurement data graphically and share customised test reports quickly.

Simply choose an ELS loadcell and a set of grips, and you are ready to enjoy enhanced testing with the power of VectorPro.

Key features

Design

Intuitive icon-driven interface and workspace

Advanced 'drag and drop' test routine builder

Personalised user accounts and favourites

Touch screen enabled

Control

Stress/strain machine control

Active or basic load control

System deflection compensation

Manage user permissions and audit trail

Report

Built-in data calculations

Customisable test report templates

Print results to Adobe PDF format

Export data to Excel and other data packages

Universal testing machines range

The OmniTest range of universal testing machines are available in load capacities from 0.5 kN - 50 kN to meet the specifics of your material, component and product testing requirements.

0.5/1/2.5 kN

110 - 550 lbf

5/7.5 kN

1,100 - 1,650 lbf

10/25/50 kN

2,200 - 11,000 lbf

Sensors

The OmniTest universal testers use Mecmesin's range of high-resolution precision Enhanced Load Sensors (ELS) to record tensile and compressive loads.

ELS

A precision loadcell connects directly to an OmniTest or MultiTest-dV stand and communicates with VectorPro MT software, enabling sophisticated test routines for materials testing applications.

Enhanced Load Sensors (ELS)

The ELS range of interchangeable tension and compression loadcells is specially adapted to the OmniTest universal testers. They can also be used when upgrading a MultiTest-dV stand to become a MultiTest-dV(u) materials tester.

To ensure that you have the optimum selection to meet your tension and compression testing needs, eighteen different models are available to cover the range from 2 N right up to 50 kN.

Loadcell capacity, range and accuracy

Each loadcell reads from zero to its full nominal capacity and is accurate to ±0.5% of reading from 2 - 100% of range. Class 0.5 according to ISO 7500-1

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and loadcell re-calibration. Talk to one of our engineers or your local national distributor to find out more.

ELS (2 - 500 N)

The ELS comprises a sturdy dovetailed-mounting box with an internal loadcell, complete with a small fixing thread and occupies minimal space.

Capacities:

- 2 N (0.55 lbf)

- 5 N (1.1 lbf)

- 10 N (2.2 lbf)

- 25 N (5.5 lbf)

- 50 N (11 lbf)

- 100 N (22 lbf)

- 250 N (55 lbf)

- 500 N (110 lbf)

ELS-S (100 N - 5 kN)

The ELS-S comprises the same dovetailed-mounting box with an external S-beam loadcell situated beneath. It provides a more rigid secure connection for large, heavy grips and fixtures than the ELS.

Capacities:

- 100 N (22 lbf)

- 200 N (44 lbf)

- 500 N (110 lbf)

- 1000 N (220 lbf)

- 2500 N (550 lbf)

- 5000 N (1100 lbf)

ELS-T (7.5 - 25 kN)

The ELS-T comprises a mounting box with an external S-beam loadcell situated beneath. It is designed for use with the OmniTest 7.5 and the OmniTest twin-column test frames for the testing of higher loads and provides a rigid secure connection for large, heavy grips and fixtures.

Capacities:

- 100 N (22 lbf)

- 200 N (44 lbf)

- 500 N (110 lbf)

- 1000 N (220 lbf)

- 2500 N (550 lbf)

- 5000 N (1100 lbf)

- 7500 N (1650 lbf)

- 10000 N (2200 lbf)

- 25000 N (5500 lbf)

ELS-P (20 - 50 kN)

The ELS-P comprises a mounting box with an external Pancake loadcell situated belneath. It is designed for use with the OmniTest 50kN twin-column test frame for testing of higher loads and provides greater immunity to extraneous "off-axis" loads.

Capacities:

- 20000 N (4400 lbf)

- 50000 N (11000 lbf)

Extensometer compatibility for precision measurement

Enhance the accuracy of your OmniTest universal tester even further with a range of extensometers tailored to different testing applications.

Whether you require short-travel, long-travel, or non-contact measurement, our range of compatible extensometers ensure precise strain measurement across a variety of materials and test setups.

Short-travel

Ideal for metals, composites, and rigid plastics with minimal elongation

- Highly accurate strain measurement for low-extension materials

- Clip-on or spring-loaded options for easy attachment

- Compliant with ISO 6892 and ASTM E8 standards

Long-travel

Ideal for polymers, rubbers, and other materials with high elongation

- Measures large extensions with precision

- Suitable for highly elastic materials and tensile tests

- Meets ASTM D638 and ISO 527 requirements

Non-contact

Ideal for delicate specimens and advanced strain analysis, automating the process of capturing strain

- No physical contact—eliminates specimen influence

- High-resolution digital tracking for precise, real-time strain data

- Automatic gauge length detection and tracking

Accessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesKey specs

Key specs

Tension & compression

Available loadcells (all measure from zero to the value indicated in the table below)

| Model | ELS 2 | ELS 5 | ELS 10 | ELS 25 | ELS 50 | ELS 100 | ELS 250 | ELS 500 |

|---|---|---|---|---|---|---|---|---|

| N | 2 | 5 | 10 | 25 | 50 | 100 | 250 | 500 |

| lbf | 0.44 | 1.1 | 2.2 | 5.5 | 11 | 22 | 55 | 110 |

| kgf | 0.2 | 0.5 | 1 | 2.5 | 5 | 10 | 25 | 50 |

| Model | ELS-S 100 | ELS-S 200 | ELS-S 500 | ELS-S 1000 | ELS-S 2500 | ELS-S 5000 | ELS-T 7.5 |

|---|---|---|---|---|---|---|---|

| N | 100 | 200 | 500 | 1000 | 2500 | 5000 | 7500 |

| lbf | 22 | 44 | 110 | 220 | 550 | 1100 | 1650 |

| kgf | 10 | 20 | 50 | 100 | 250 | 500 | 750 |

Accuracy

When calibrated as part of a system, accuracy is ±0.5% of reading down to 2% of range, suitable for use with Class 0.5 systems according to the requirements of ISO 7500-1. Eg, ELS 100 when measuring 10N is accurate to ± 0.05 N or when measuring 50N it is accurate to ± 0.25 N.

Resolution

1:50,000 filtered from 24 bit

Units of measurement

mN, daN, N, kN, gf, kgf, ozf, lbf

Sampling rate

20 kHz

Data-acquisition rate

1000 Hz

Displacement

Maximum crosshead travel (between limit switches)

- 0,5

1186 mm (47") - 1

986 mm (39") - 2,5

507 mm (20") - 5/7,5

650 mm (25.6")

Accuracy

- 0.5/1/2.5

±0.13mm per 300mm travel

±0,005" per 11,8" travel - 5/7.5

±0.1% of indicated position or ± 0.01mm, whichever is greatest

Resolution

- 0.5/1/2.5/5/7.5

0.001mm (0.00004")

Speed

Range

0.01 - 1200 mm/min (0.0004 - 47.2"/min)

Accuracy

Better than ±2% of indicated speed or ± 0.02 mm/min, whichever is greater*

* See help.mecmesin.com for additional info

Resolution

0.001 mm/min (0.0004"/min)

Dimensions

OmniTest 0.5

OmniTest 1

OmniTest 2.5

OmniTest 5

OmniTest 7.5

Headroom/vertical daylight (vertical space to fit sample)

- 0.5

1205 mm (47") - 1

1005 mm (40") - 2.5

526 mm (21") - 5/7.5

750 mm (30")

Throat depth (column to centre-line of loadcell)

- 0.5/1/2.5

63.5 mm (2.5") - 5/7.5

125 mm (4.9")

Height

- 0.5

1616 mm (64") - 1

1416 mm (56") - 2.5

941 mm (37") - 5/7.5

1089 mm (43")

Width

- 0.5/1/2.5

290 mm (11.4") - 5/7.5

330 mm (13")

Depth

- 0.5/1/2.5

414 mm (16.3") - 5/7.5

570 mm (22.5")

Weight

- 0.5

31 kg (68 lbs) - 1

27.5 kg (61 lbs) - 2.5

24 kg (53 lbs) - 5/7.5

70 kg (155 lbs)

Common specifications

Voltage

230V AC 50 Hz or 110V AC 60 Hz

Power (max)

120 - 250W

Operating temperature

10 - 40°C (50 - 104°F)

Humidity range

Normal industry and laboratory conditions, non-condensing 30 - 80% RH

Software and communications

Stand connectivity

USB (for PC communications), Extensometer input, 2 additional ELS inputs, Digital I/O

PC requirements (recommended)

Intel Core i5, 8 GB RAM, SSD, USB 2.0 or 3.0 port, graphics (Full HD/1080p). Internet connection required for Vector Cloud Solutions.

Operating system

64 bit only recommended. Windows 10 or 11 Pro or better.

Data output

PDF, XLSX, HTML, CSV, TXT, email and image files can all be exported from VectorPro software