Lipstick bullet break resistance testing

Solution

- Compression tester and digital gauge

- Custom lower fixture to hold lipstick product

Benefits

- Quick and easy testing in the QC lab

- Clear indication of pass or fail values

The Mecmesin system has helped us deliver a better product to our customers with less breakages and leaks. The Tornado is used every 2 hours to ensure the torque of the nail varnish caps are within working range.

Gregorio Suarez, Quality Control and Production Manager

Barry M Cosmetics Ltd.

Requirement

Barry M Cosmetics Ltd. are the leading British colour cosmetics brand, offering a comprehensive range of lipsticks and lip paints. The company is famous for on trend innovation – bright colours, even colour changing, plus naturals, in a choice of finishes from matte to satin—all with the Cruelty-Free formulation/ingredients pledge. These products must provide a smooth flow onto the lips for application control and an expensive-feeling moisture-rich quality texture, whilst delivering a long-lasting effect and skin protection. The solid bullet’s material properties need to be resilient and durable under application stresses – typically a cantilever bending load.

Barry M’s skilled cosmetics product designers and formulation chemists needed a quick and straightforward breakage test procedure with clear, immediate results for R&D and QA purposes.

Solution

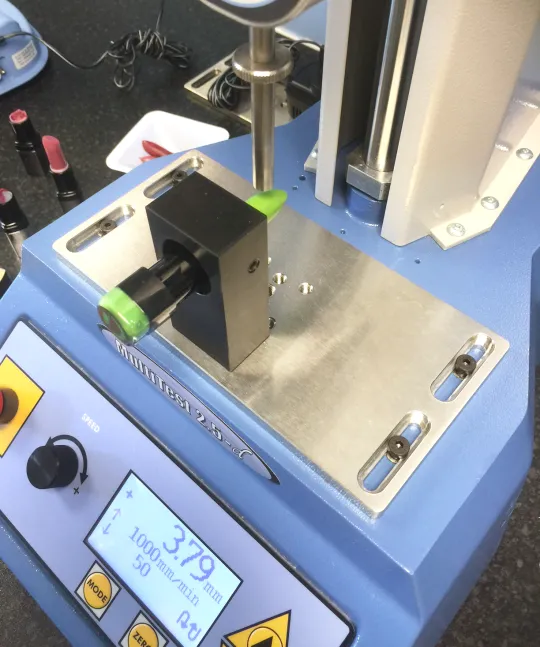

Mecmesin supplied a MultiTest 2.5-d motorised test stand with an AFG digital force gauge – the ideal configuration for quick and straightforward routine compression testing. The test stand is compact for a laboratory benchtop and the 50 N capacity of the gauge enables optimum accuracy for the load range expected. The gauge and the stand communicate seamlessly for control and ease-of-use.

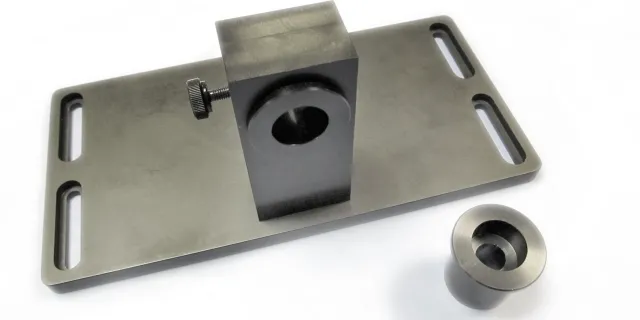

Mecmesin’s custom lipstick fixture securely holds the test sample horizontally, perpendicular to the smooth, flat-tipped probe’s loading direction. The lipstick is therefore bent, not cut, although the material may fail in shear, which would be valuable information. This gripping solution also enables contact at a repeatable distance along the bullet, which is most vulnerable when new—at its initial maximum length—the worst time for the customer to experience a breakage resulting in maximum brand reputation damage. The peak force is captured by the gauge for ultimate break strength comparison.

Barry M aims to let its customer choose a lipstick for the look and to be confident it will perform; ground-breaking without breaking—or shearing, fracturing or crumbling.

Test equipment

- MultiTest 2.5-d motorised test stand (replaced by MultiTest 2.5-dV)

- AFG 50 N Advanced Force Gauge (or other digital gauge, VFG touchscreen)

- Special lower fixture for lipstick bullet testing