Fishing net tensile strength testing to ISO1805 and ISO1806

Solution

- Software-controlled tensile tester

- Custom-designed bollard grips match to net rope gauge

Benefits

- Touch-screen option to run batch testing with optimum repeatability

- Software environment allows bespoke testing and reporting of additional data

Requirement

Fishing nets are one of the key tools in commercial fishing and there are many types of active and passive netting gear available. The breaking of nets during fishing is very common, causing problems for the fishery and to the environment. If nets are lost or abandoned, the result is undesirable “ghost gear” that pollutes the marine environment and harms sea life.

Understanding the mechanical properties of the mesh and knotted structures of fishing nets is fundamental for net manufacturers when designing products, which must withstand the heaviest of weather conditions and the degenerative effects of heavy pollutants and extremes of temperature – all factors which affect the strength and service life of fishing nets. Measures to optimise the performance and longevity of the netting may include coatings for anti-fouling and rope preservation. The effects of these treatments on the mechanical strength of the product must be evaluated.

Once in service after a certain period in the sea it is important for users of fishing nets, such as fish farmers, to evaluate the loss of resistance within the net and to know how far the mesh can elongate. This helps determine whether nets can continue to be used or require imminent replacement.

ISO 1805 test standard “Fishing nets: Determination of breaking force and knot breaking force of netting yarns” provides a recognised method for objectively testing the netting yarns.

ISO 1806 test standard “Fishing nets: Determination of mesh breaking force of netting” provides a recognised method for objectively testing the netting as a mesh.

Solution

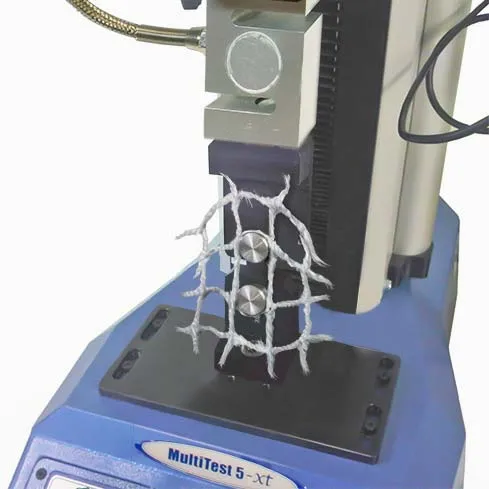

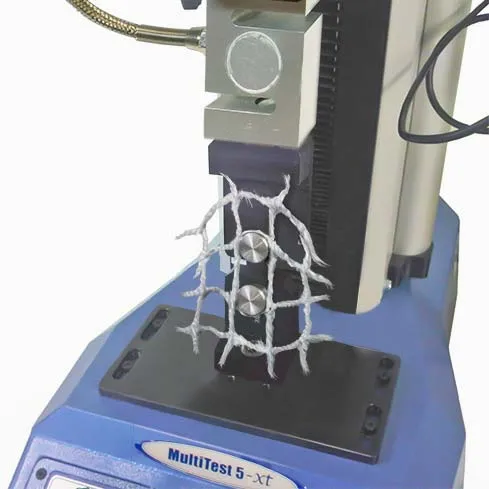

Mecmesin has worked with several fishing net manufacturers including a leading producer from Norway, who relies on the Mecmesin MultiTest 5 tensile tester for measuring their mesh breaking force.

Mesh from the net is tested in dry and/or wet conditions. A sample of mesh is cut to include a central ‘cell’ surrounded by at least one cell on all sides. The central mesh element is placed at right-angles between 2 roller pins at a known separation distance. Rope bollard grips ensure that the netting material is not subject to local stress raisers at their contact points. Tensile load is applied to the mesh at a constant rate of extension and force is applied such that the mesh will break around 20 seconds later. The maximum force in tension is recorded in daN for each of 10 different mesh specimens taken from the same net and tested in a batch.

In addition to fulfilling the requirements of ISO 1806, the Mecmesin tensile tester also measures the elongation of the mesh in absolute values (mm or inch) and % stretch compared to its initial length. Issuing a tailored report, to include details of the net with all test results, is achieved thanks to the flexibility of Emperor test software. The flexibility of this Mecmesin tensile tester is such that it can also be used to test the tensile strength of the netting yarn itself in accordance with the requirements of ISO 1805.

Test equipment

- MultiTest software-controlled tensile tester

- Loadcell rated to maximum expected loading

- Bollard grips (pair) matched to yarn gauge