The successful design and production of plastic components requires careful attention to be paid to many elements. The choice of plastic material depends on the desired performance characteristics - will parts be under constant load? Will they come into contact with chemicals? If the parts are made of different materials, how do the materials work together?

Plastic materials shrink at different rates, which impacts part integrity. For instance, thermoplastics are heated at high temperatures and injected into a mould cavity. As they cool, they shrink and thick cross sections cool at a lower rate than thin cross sections, so are likely to cause distortion of the part after removal from the mould . By adding ribs to the design it can minimise distortion and increase rigidity and strength.

Assembling plastic parts can be done in several ways:

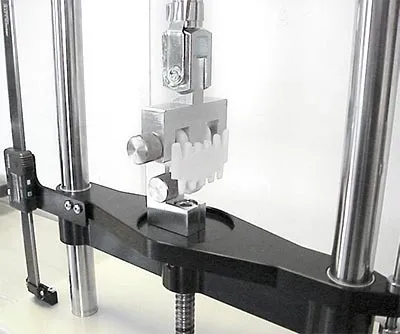

Mechanical: Press-fit and Snap-fit are popular techniques. If a product has to be dis-assembled at some point in its life – e.g. a removeable battery pack,– then it is the preferred assembly method especially for low-volume applications when the cost of capital equipment is high compared to the component value.

Adhesives: When applications contain materials that are not compatible, adhesives are usually the preferred method for a permanent solution.

Friction and heat methods: Ideal when a permanent or tamper-proof seal is required. Methods include Ultrasonic Assembly, Vibration Welding and Spin Welding.

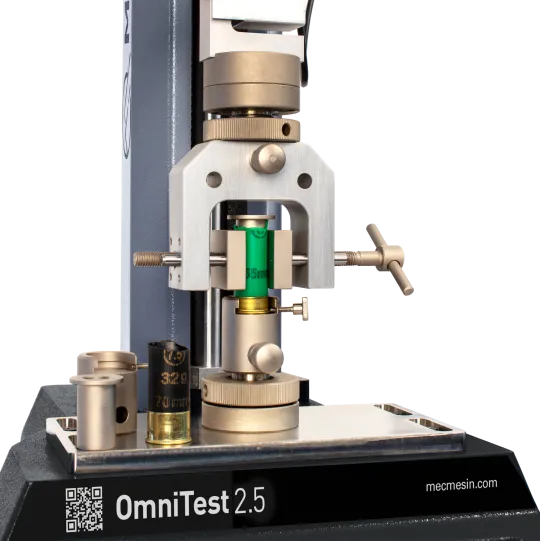

Quality-control checks for assembled components often revolve around their mechanical strength and measuring their ability to withstand stresses and strains during their operation over a product lifecycle. Using Mecmesin force and torque measurement equipment is a cost-effective way of performing those QC checks.