Plastic chain conveyor tensile strength test

Solution

- Motorised test stand, gauge display and software

- Clamping fixtures and accessories designed for the product tested

Benefits

- System able to apply and measure high loads

- Simple test procedure for production staff use

- Data capture for further analysis

Requirement

The customer manufactures rigid plastic links which, when assembled, form a conveyor. The assembled link may be subject to significant stress in use during its lifetime, so it is important that the link can withstand a minimum load of 3000 N to ensure there are no weaknesses in the material of the manufacturing process.

The requirement was to provide a complete solution to perform a destructive test on the plastic links using an affordable yet simple-to-use test system. The maximum load and deformation of the sample were to be recorded and the curve of force/deflection plotted on a PC. Two systems were required for use in the production area of the factory by semi-skilled production operators.

Solution

The customer manufactures rigid plastic links which, when assembled, form a conveyor. The assembled link may be subject to significant stress in use during its lifetime, so it is important that the link can withstand a minimum load of 3000 N to ensure there are no weaknesses in the material of the manufacturing process. The requirement was to provide a complete solution to perform a destructive test on the plastic links using an affordable yet simple-to-use test system. The maximum load and deformation of the sample were to be recorded and the curve of force/deflection plotted on a PC. Two systems were required for use in the production area of the factory by semi-skilled production operators.

Mecmesin provided a customised solution based around a 5000 N capacity motorised test stand fitted with S-Beam loadcells and a digital height scale for measuring crosshead movement. It provided the necessary repeatability of results by virtue of operating at a fixed speed of 50 mm/min and using the high-speed peak-capture facility of the AFTI display to record the maximum tensile force as the plastic link suddenly snapped.

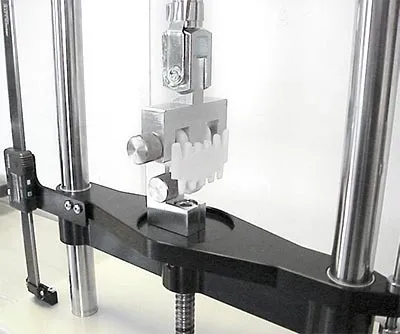

A gripping fixture using the location holes of the link and quick-fitting holding pins was specially designed. The software DataPlot-X was configured to start taking data when a small pre-load of 10 N was applied to the link (to take up any slack within the grip/link) and the test was conducted until the plastic link broke at forces in the region of 4000 N.

Test equipment

- M5KNE Motorised Test Stand fitted with Digital Height Scale

- S-Beam Loadcells 5 kN

- AFTI Displays

- Custom-made Gripping Fixtures

- DataPlot-X Software and Interface Cables