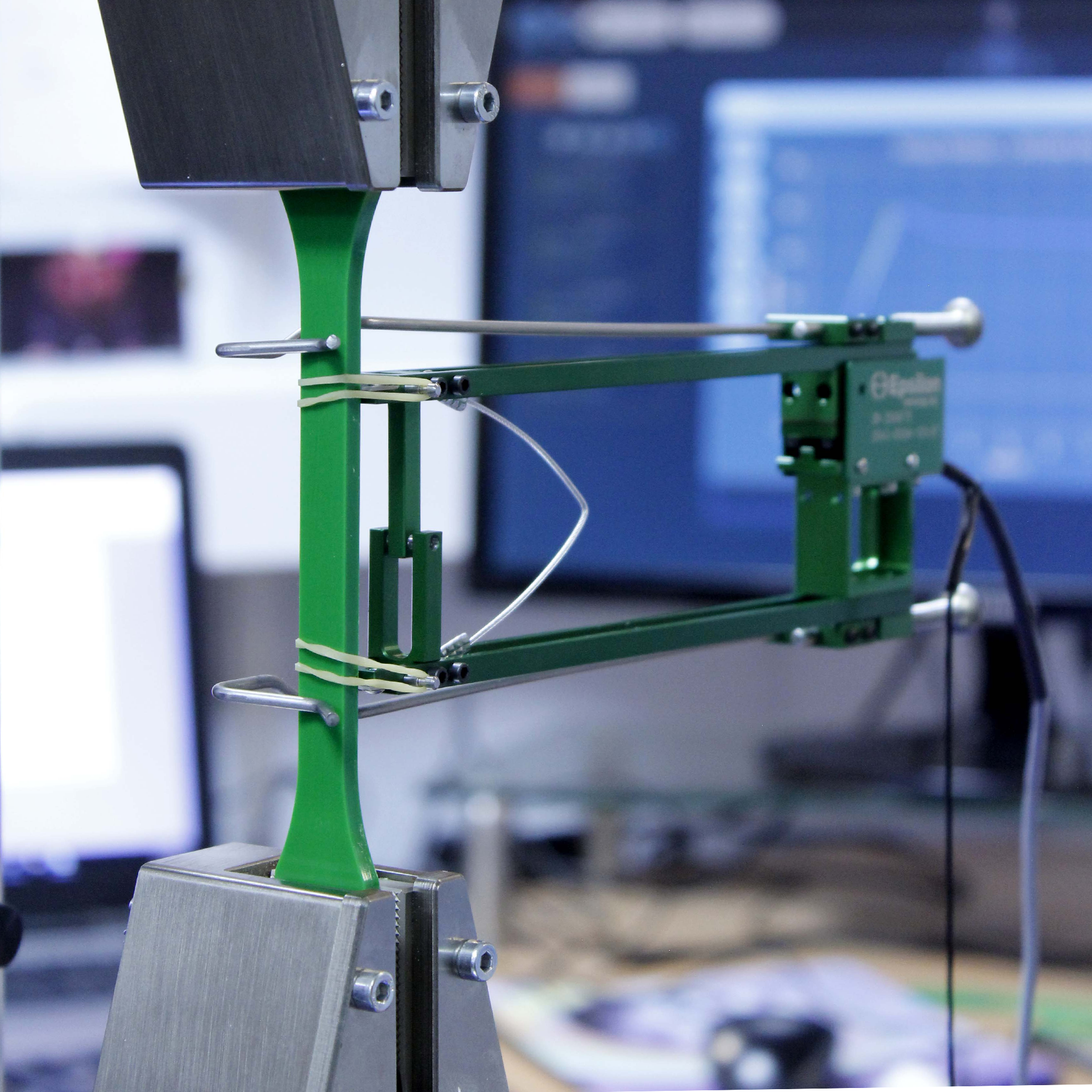

Universal Testing Machines

Our universal testing machines (UTM) are capable of performing a range of tests, including tensile and compression tests, following international and industry-specific standards.

One of the key factors in our universal testing machines is the flexible software used to program the testing methods. This software enables explicit control over load application and deformation rate, which is particularly important when testing raw materials.

Explore our full range below.

Our universal testing machines (UTM) are capable of performing a range of tests, including tensile and compression tests, following international and industry-specific standards.

One of the key factors in our universal testing machines is the flexible software used to program the testing methods. This software enables explicit control over load application and deformation rate, which is particularly important when testing raw materials.

Explore our full range below.