The VortexPro is a top of the range torque tester controlled by VectorPro software running from your computer. Accurate, easy to use and optimised for measuring static torque up to 10 N.m.

The ultimate flexible solution for automated torque testing of a wide range of containers, closures, components and assemblies.

The VortexPro Touch is a multi-functional torque tester controlled by a touchscreen console running VectorPro software. Rated up to 10 N.m it is accurate, easy to use and ideal for standalone use.

Its versatility as an automated torque tester makes it the perfect solution for routine testing of a wide range of closures and components.

The VortexPro is a top of the range torque tester controlled by VectorPro software from your computer. Accurate, easy to use and optimised for measuring static torque up to 10 N.m.

The ultimate flexible solution for automated torque testing of a wide range of closures and components.

Looking for the right testing solution?

Overview

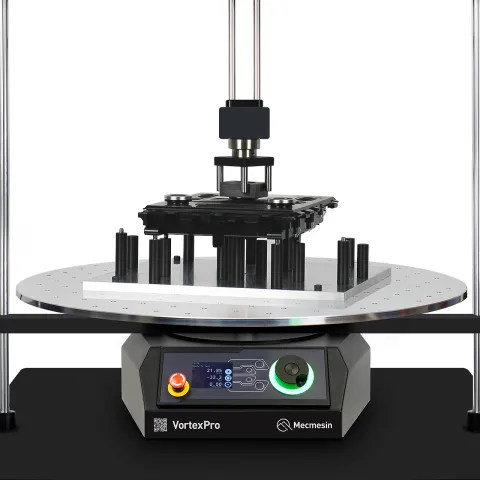

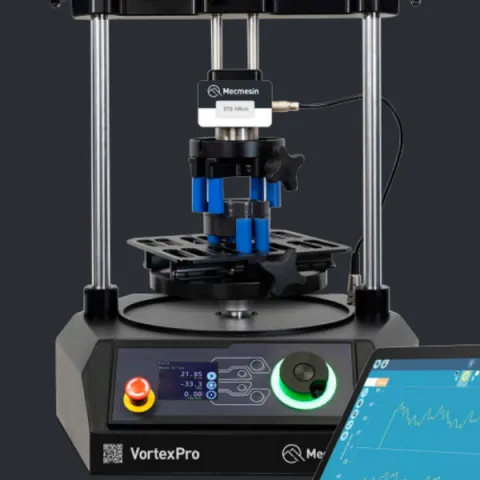

VortexPro and VortexPro Touch torque testers

A multi-functional torque tester controlled by VectorPro torque testing software, from a touchscreen console or your computer. Measure static clockwise or counter-clockwise torque up to 10 N.m. Accurate, easy to use and and ideal for larger test specimens.

Its versatility as an automated torque tester makes it the perfect solution for routine testing of a wide range of closures and components.

Test frame

Automated torque tester (Twin-column)

The motorised test frame of the VortexPro is developed for static torque testing up to 10 N.m, featuring a twin-column frame design and precision motor, with space for larger test specimens.

Test specimens up to 440 mm tall and 280 mm wide can easily be tested in both clockwise and counter-clockwise directions.

Powered by VectorPro™ test software from your computer, or touchscreen console, the refined footprint of the test system makes it an ideal bench-top device for use in laboratory or production environments.

Torque sensors

Interchangeable sensors, from 0.3 - 10 N.m

A range of interchangeable ETS torque sensors are specially adapted to the VortexPro and HelixaPro. Connect a torque sensor to the test frame and the calibration characteristics are automatically recognised by the test system and software without any input from the operator.

Five different sensors are available with nominal capacities ranging from 0.3 N.m up to 10 N.m. This ensures that you have the optimum selection to meet all your torque testing needs. Measurement accuracy is an outstanding ±0.5% of the sensor capacity.

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Software

Powered by VectorPro™

VectorPro™ testing software is at the heart of our VortexPro and VectorPro Touch torque test systems. VectorPro runs on any Windows computer, controlling the motorised test frame and capturing test data at 1,000 Hz from the ETS torque sensor and angle encoder of the frame.

Step-by-step test routines can be quickly and easily created according to the exact requirements of your testing procedures. Configured tests are easily selected on the home screen with a single click or touch.

Realtime plotting of measurement data on an interactive graph enables the operator to identify precisely how the test specimen is performing. Preset calculations analyse the data and can determine whether the specimen has met the pass/fail criteria of the quality-control specifications.

At the end of the test, the powerful reporting module within VectorPro™ allows the operator to issue a test report as a PDF. Additionally, the data can be exported to Excel or to the network for further analysis by a Statistical Process Control (SPC) package.

Grips and fixtures

Standard fixtures and custom grip design

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin has designed a range of torque grips to hold a variety of components. They include chucks and mandrels to hold plastic and metal closures, fixing tables to secure bottles and containers plus many more.

The varying nature of specimen sizes and shapes often makes it necessary to design and produce a special grip. Mecmesin's team of design engineers can work with you to develop the best grip for your specimen. These are then produced on our 3D printers to create lightweight, precision fixtures or, for higher load applications, they are made from metal at our machine-shop.

Emperor™ Software

VectorPro® software

VectorPro is an advanced torque testing software package developed to perform torque testing on components and products. Capture measurement data graphically and share customised test reports quickly.

Simply choose an ETS loadcell and grips or fixtures for your test specimen, and you are ready to enjoy enhanced testing with the power of VectorPro.

Key features

Design

Intuitive icon-driven interface and workspace

Advanced 'drag and drop' test routine builder

Personalised user accounts and favourites

Touchscreen enabled

Control

Torque/angle machine control

Active torque-hold and cycle functions

Manage user permissions and see audit trail

Digital I/O's for automation of testing

Report

Built-in data calculations

Customisable templates for test reports

Print or email test results automatically

Export data to Excel and other data packages

Torque sensors

The Enhanced Torque Sensors (ETS) range of interchangeable torque sensors are specially adapted for the HelixaPro and VortexPro test systems.

Plug and play for automatic calibration with availability to suit all requirements in capacities from

We also design customised solutions for applications requiring torque measurement up to

ETS torque sensors

The Enhanced Torque Sensors (ETS) range of interchangeable torque sensors is specially adapted to the HelixaPro and VortexPro test systems.

They plug into the frame of the precision torque tester and their calibration characteristics are immediately recognised by the software without any input from the operator.

To ensure that you have the optimum selection to meet all your torque testing needs, eight different sensors are available. All sensors measure from zero and cover the range from 0.1 N.m right up to 10 N.m .

A range of grips, fixing tables and chucks is available to hold your specimens. Connection to each ETS sensor is via a ⅜" male square drive (ETS 0.3 - 10) or via a ¼" female hexagonal drive (ETS 0.1 - 0.2)

Sensor capacity, range and accuracy

Each sensor reads from zero to its full nominal capacity (listed below). Measurement accuracy is an outstanding ±0.5% of the sensor capacity.

| Model ETS | 0.1* | 0.2* | 0.3 | 1 | 1.5 | 3 | 6 | 10** |

|---|---|---|---|---|---|---|---|---|

| N.m | 0.1 | 0.2 | 0.3 | 1 | 1.5 | 3 | 6 | 10 |

| kgf.cm | 1 | 2 | 3 | 10 | 15 | 30 | 60 | 100 |

| lbf.in | 0.9 | 1.8 | 2.7 | 9 | 13 | 26 | 50 | 90 |

*Not recommended for VortexPro

**Not recommended for HelixaPro

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and torque sensor re-calibration. Talk to one of our engineers or your local national distributor to find out more.

ETS 0.1 - 0.2

Recommended for HelixaPro only. Fitted with a ¼" female hexagonal drive for connection to grips and test fixtures.

ETS 0.3 - 10

Interchangeable torque sensors for the HelixaPro and VortexPro. Fitted with a ⅜" male square drive for connection to grips and test fixtures.

ETS 15 - 30

For custom applications requiring torque measurement up to 30 N.m, the VortexPro test frame and sensor capacity can be customised to meet your test requirements.

Accessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesKey specs

Key specs

Torque

Test frame (rated torque)

| N.m | 0 - 10 |

|---|---|

| kgf.cm | 0 - 100 |

| lbf.in | 0 - 90 |

Sensors available (all measure from zero to the value indicated in the table below)

| Model ETS | 0.3 | 1 | 1.5 | 3 | 6 | 10 |

|---|---|---|---|---|---|---|

| N.m | 0.3 | 1 | 1.5 | 3 | 6 | 10 |

| kgf.cm | 3 | 10 | 15 | 30 | 60 | 100 |

| lbf.in | 2.7 | 9 | 13 | 26 | 50 | 90 |

Accuracy

±0.5% of full scale

Resolution

1:50,000

Units of measurement

mN.m, N.cm, N.m, kgf.cm, gf.cm, ozf.in, lbf.in, lbf.ft

Sampling rate

Selectable: 10 - 1,000 Hz

Angle

Angular rotation (from tared position)

Max. 2,999 revs

Accuracy

±0.2°

Resolution

0.1°

Speed

Range

0.1 - 30 rev/min (clockwise or anticlockwise)

Accuracy

±1% of indicated speed

Resolution

0.001 rev/min

Static weights

Axial load via masses on platen

60 N (maximum)

Dimensions

Maximum headroom

483 mm (without fixtures)

Maximum travel of adjustable carriage

182 mm

Width between columns

280 mm

VortexPro test frame

Height

1000 mm

Width

- VortexPro

400 mm - VortexPro Touch

630 mm (inc. console)

Depth

372 mm

Weight

- VortexPro

20 kg - VortexPro Touch

23 kg (inc. console)

Common specifications

Maximum power requirements

120 W

Voltage

230 V AC 50 Hz or 110 V AC 60 hz

Operating temperature

10 - 35°C (50 - 95°F)

Humidity range

Normal industry and laboratory conditions (30-80%), non-condensing

Software and communications

Stand connectivity

USB (for PC communications, Digital I/O (8 inputs, 8 outputs)

Console connectivity (VortexPro Touch)

1 x USB-C (Power/Data), 3 x USB-A (Data)

PC requirements (recommended)

Intel Core i5, 8 GB RAM, 128 GB SSD, USB 2.0 or 3.0 port, graphics (Full HD/1080p). Internet connection required for Vector Cloud Solutions.

Operating system

Windows 10 or 11 Pro (recommended) or better, 64 bit only

Data output

PDF, XLSX, HTML, CSV, TXT, email and image files can all be exported from VectorPro software