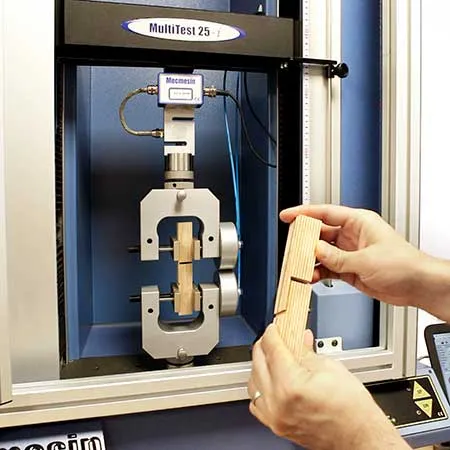

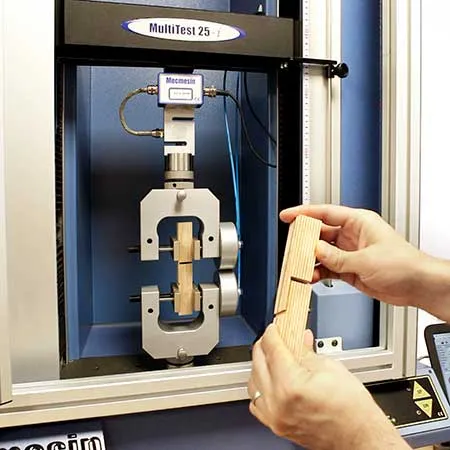

Lap shear testing of plywood

Solution

- High-capacity twin-column software-controlled tensile tester

- Pneumatic planar vice grips with serrated jaw faces

Benefits

- Software control runs the test to the standard method

- Quick-change fixtures optimise efficiency and repeatability

- Automatic calculation of the relevant properties of the specimen

- Consistent output of results report in customer-designed format

Requirement

Estonian Plywood (part of the Lemeks/Tarmeko group) is a leading manufacturer of uncoated birch plywood; harvested from sustainable well-managed forests. Their years of expertise in raw materials, preparation and plywood construction has seen them build an unrivalled reputation for delivering cross-bonded birch veneers with outstanding strength properties.

Plywood, which is made with glues and resins that bond thin plies of wood into structural sheets, is used extensively for a variety of applications including construction, flooring, outdoor decking and vehicle panelling. As significant components in load-bearing structures, it was important for Estonian Plywood to test the physical strength of their bonded products to ensure they meet the rigorous performance standards required.

Solution

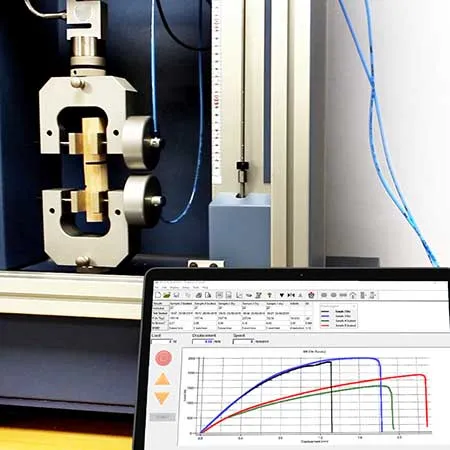

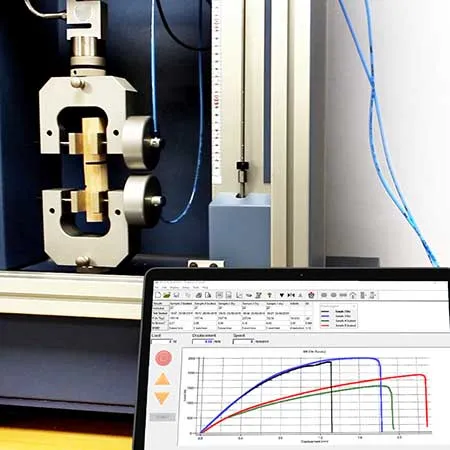

The European Norm EN314-1 stipulates methods for determining the bonding quality of veneer plywood, blockboard and laminboard by shear testing. Mecmesin’s MultiTest 50-i tensile tester was the ideal choice as a bench-top model, capable of applying the high loads necessary to separate the bonded plywood in the shear direction.

In accordance with EN314-1 tests are conducted on specifically-prepared wet specimens, which are wiped dry. To minimise the risk of wood samples slipping during testing, a pair of pneumatically-operated vice grips were used to apply a constant clamping force via serrated jaw faces, which bite securely into the wood.

The motor inside the rigid twin-column frame of the MultiTest 50-i is driven by Mecmesin’s Emperor control software at a constant rate, ensuring optimum repeatability. The breaking load in newtons (N) and the shear strength in N/mm² are calculated automatically by the software and included in test reports configured to Estonian Plywood’s needs.

Test equipment

- MultiTest 50-i software-controlled tensile tester

- ILC-T 25kN loadcell

- Pair of Pneumatic Vice Grips (MecS240G-S50)