High Performance Plasma Coatings

Solution

- High-capacity software-controlled tensile tester

- 50 kN rated wedge grips and selection of loadcells

Benefits

- Independent in-house, testing

- Adherence to industry standards

The system is simple to use and produces good graphical data.

Roy McIntyre, Technical Manager

Alphatek Hyperformance Coatings

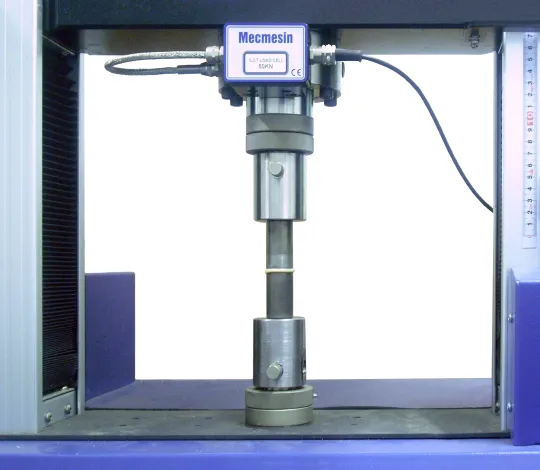

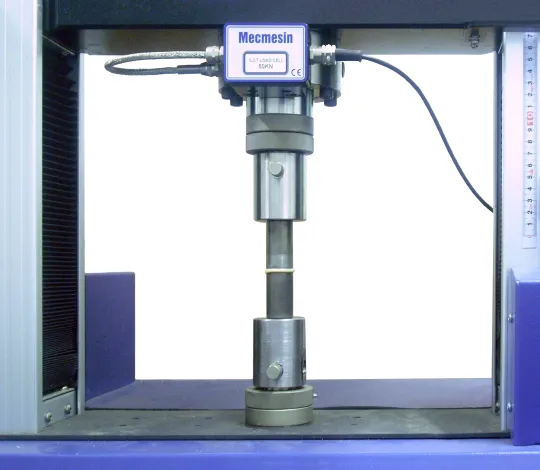

Requirement

Alphatek Hyperformance Coatings Ltd. are a coatings company that applies wear, corrosion, heat or electrically resistive coatings, supplying to many different industries. The quality of their plasma coatings are completely dependent on adhesion to their substrates, and must conform to industry standard ASTM C633. The requirement was to determine the force required to pull test samples of coating off. Two metal rods with coated surfaces are stuck together with a powerful bonding agent of a kind that does not compromise the properties of their coating. Once cured, the rods are pulled apart in a direction normal to the plane of the joint. The glue may fail, but the coatings must withstand the minimum standard force. Separation forces of up to 48 kN are reached.

Solution

Mecmesin supplied a twin-column test stand with 50 kN intelligent loadcell to exert the high forces required. Quick-change grip adapters hold each end of the test rod for perfectly aligned tensile loading. Emperor™ software controls the whole process via a library of test programmes, and the characteristics of the sample under load are displayed as a real-time graph. With data sampling up to 1000 Hz, and calibrated compensation for deformations of the test stand itself, the rapid phase of failure can be very accurately profiled. By including quality-standards values in the test programme calculations, instant pass/fail indication can be given. All data are fully recorded for subsequent analysis, and comparison of sample performance. The test facility replaces third party analysis, provides rapid turn-around, and complete reproducibility of test conditions, all in a system that is affordable, versatile, and very easy to use.

Test equipment

- MultiTest 50-i twin column tensile testing machine

- 50 kN ILCP intelligent loadcell

- 50 kN rated grips and quick-change grip adapters