Efficiency in the time of COVID Scaling syringe and vial manufacturing

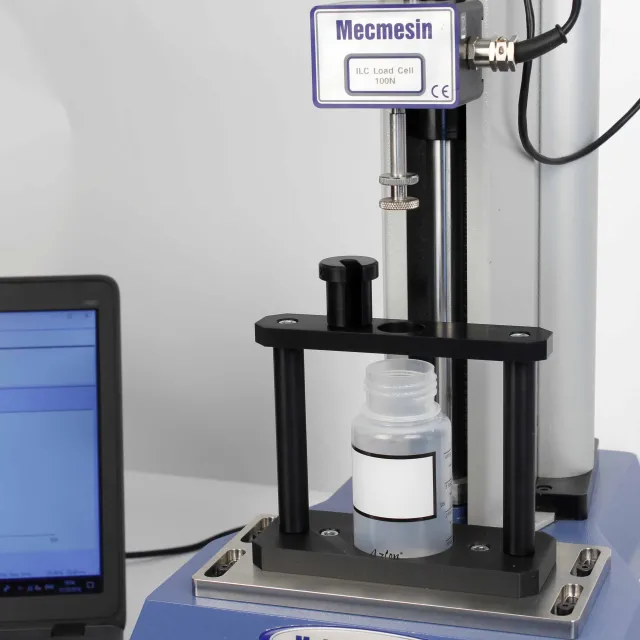

Affordable syringe and vial testing

The humble syringe is currently the only vehicle that can deliver what is arguably the world’s most valuable substance, the COVID-19 vaccine. Yet, syringes are in short supply.

According to one of the globe’s biggest syringe makers, Hindustan Syringes & Medical Devices (HMD), 10 billion syringes are needed to vaccinate but 60% of the global population. This has seen syringe (and glass vial) manufacturers racing to increase output to meet demand. But such hurried escalation of production comes with its own challenges – one being quality control.

Making syringes & vials safe

To help manufacturers expand their quality testing rapidly and affordably, Mecmesin has produced a Syringes and Vials Testing Tips whitepaper. It provides useful information to help both small and large businesses to expand the quality testing of their components, materials and products, quickly and affordably.

“It is the culmination of our 40 plus years of experience and expertise in the field of force and torque testing for quality control,” explains Robert Egginton, UK Sales Manager for Mecmesin.

“We’ve collated all the data we have into a single whitepaper, which we are making freely available to those who need a quick reference guide to the type of testing that can be done in the syringes and vials arena.”

Why test syringes and vials?

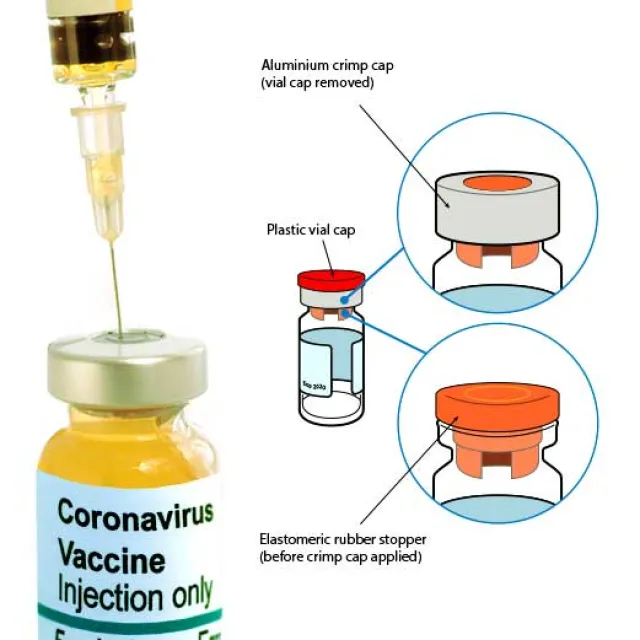

Because whether used to administer the COVID vaccine or some other medicine, needles and syringes need to perform precisely to specification. If they do not, they may seriously limit the ability of a health care professional to treat their patient effectively and safely.

The medical devices and pharmaceuticals sector is highly regulated, driven by compliance and auditing processes. There are specific force and torque testing methods used to assess the quality and performance of syringes – from individual components through to the assembled device. And the same goes for the vial from which a syringe must extract the medication and vaccine.

Why download this whitepaper?

“Our whitepaper is designed to help manufacturers to design and perform the tests that are required to meet specific standards, whether those are internal company standards or industry standards.

Covering topics such as needle sharpness, penetration force, needle stiffness and fracture point, retention tests on hub and luer connectors, and much more.

Download a free copy of the Syringes & Vials Top Tip Whitepaper.