Testing rubber to materials standards

Solution

- Software-controlled UTM universal testing machine

- Understanding of raw materials properties for product and component manufacture

- Self-tightening grips

Benefits

- Accurate adherence to international standards

- Flexibility to evaluate ergonomic feedback characteristics

- Ability to test at various environmental conditions with compatible accessories

Requirement

Characterisation of materials is essential to have confidence in their performance in the manufactured products and components they are subsequently used in. In-house and external specialist facilities perform tests on specimen materials to measure and calculate their properties as a quality assurance check or to determine suitability for new processes. Vulcanised and thermoplastic (rubber) elastomers (TPE) are used in products across all industries, from vehicle tyres, insulation, dampers, bushes, seals and belts to consumer products like shoes and toys. Their elastic behaviour is the main property which determines their unique suitability in all these applications.

Two important industry standards which are implemented to characterise these materials are ISO 37 and ASTM D412.

ISO 37 – Rubber, vulcanised or thermoplastic —Determination of tensile stress–strain properties is used to calculate:

- Tensile strength (TS)—the maximum tensile stress applied in stretching a specimen to break/rupture.

- Tensile strength at break (TSb)—tensile stress recorded at the moment of rupture.

- Elongation at break (Eb)—tensile strain in the test length at breaking point.

- Stress at a given elongation (Se)—tensile stress in the test length required to produce a given elongation.

- Elongation at a given stress (Es)—tensile strain in the test length when the test piece is subjected to a given tensile stress.

- Stress at yield (Sy)—tensile stress at the first point on the stress-strain curve where some further increase in strain occurs without any increase in stress.

- Elongation at yield (Ey)—tensile strain at the first point on the stress-strain curve where some further increase in strain is not accompanied by an increase in stress.

ASTM D412 - Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers — Tension determines:

- Tensile strength—the maximum tensile stress applied in stretching a specimen to break/rupture.

- Tensile stress at a given elongation—the stress required to stretch the uniform cross section of a test specimen to a given elongation.

- Yield stress—the stress at that point on the stress-strain curve, short of ultimate failure, where the rate of stress with respect to strain, goes through a zero value and may become negative.

Both standards refer to others to standardise specimen preparation, conditioning and environmental conditions.

Solution

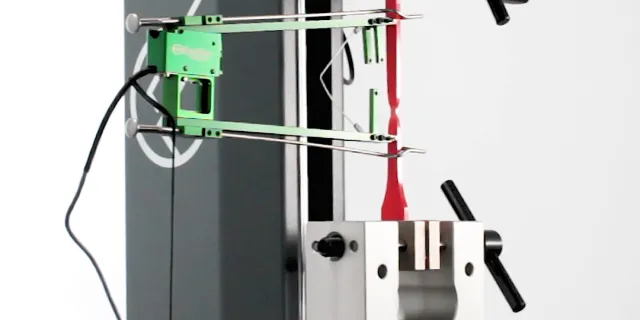

Universal testing machines (UTM) enable the determination of a range of measured values for test specimens under tensile and compression loads. Interchangeable fixtures and instrumentation connectivity provide the specific hardware apparatus to grip and measure, whilst appropriate software is essential to explicitly control the UTM and capture and calculate the necessary results. Mecmesin provided an OmniTest UTM with VectorPro software and extensometry (contact-arm) to perform these elastomeric materials tests.

Dumbbell test pieces were used, although both standards allow for O-ring specimens. Precise dimensions are indicated to ensure that the median values are representative, multiple specimens are required to test in batches. Typically, these elastomeric materials are processed in a way that causes a flow or grain in the compositional structure. Cutting of the dumbbells aligned with or at an angle of interest to the grain is a fundamental decision and is documented in the report. Eccentric roller grips were used of dimensions to grip fully across the width of the shoulders (to avoid ‘shoulder breaks’) and to automatically self-tighten.

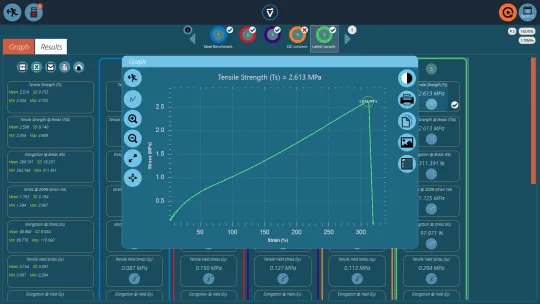

VectorPro control of the OmniTest implements the rate of extension (grip separation) that the standards require, the extensometer measures and transfers the test piece’s correct gauge length extension (strain) to calculate stress. Fundamental materials property calculations are included, and the user can apply these to the data. Returning graph values from axis points enables information such as stress at a given elongation to be found for significant or user-chosen points, e.g., 25%, 200%, 200%, etc.

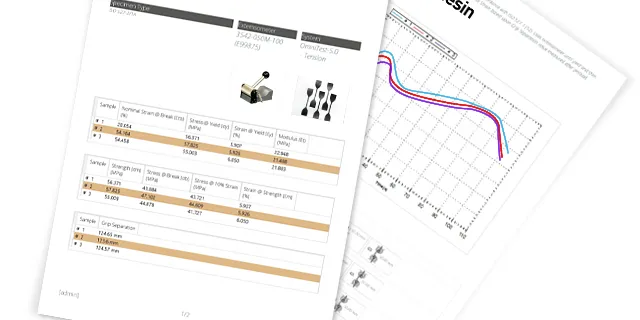

VectorPro also includes a range of report templates and an intuitive drag-and-drop GUI to place attributes, graphs and results into the document. Test particulars—sample description, preparation, type, thickness, grain orientation—can all be assigned as attributes and descriptors to fully document the procedure.

Test equipment

- OmniTest single-column UTM

- VectorPro

- Extensometer

- Roller grips