Cosmetics tube flip-cap attachment strength

![Flip cap attachment cap disassembly pull-off [PDV13140]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1685-PDV13140-web.jpg.webp?itok=WUckucX6)

Customised engineering example

Many flip-caps on flat-sealed cosmetics tubes are not designed for removal by the consumer under normal use. The cap should remain attached under the pressure of the semi-solid being squeezed through the dispensing aperture as intended.

Deliberately pulling them off to test their resistance to accidental removal led our client to request a custom fixture.

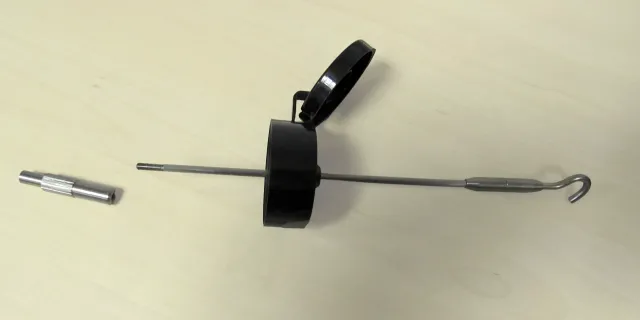

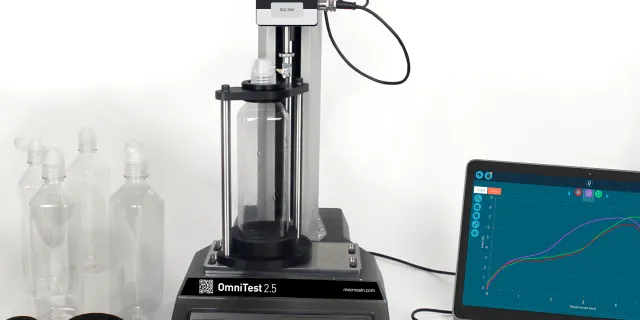

Mecmesin provided a means of pulling the cap from the inside by using a two-piece rod fitted with a hook. The rod is passed through the dispensing hole in the cap and then fitted with a locking collar. The hook is connected to the loadcell ready for the tensile tester to pull vertically. This pulls the locking collar against the underside of the cap and removes it from the tube - a simple but effective solution for reliable and repeatable testing. Switching the upper fixture to the standard flip-cap accessory enables both checks to be performed efficiently.

![Flip cap attachment cap disassembly pull-off [PDV13140]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1685-PDV13140-web.jpg.webp?itok=WUckucX6)