Test summary

Test standard ASTM D1894 enables the calculation of the static and kinetic (dynamic) coefficient of friction, µ, between two surfaces, using a horizontal plane and sled. This standard is applicable to plastic films and sheeting. Film is defined as material less than 0.254 mm thick and sheeting defined as being thicker than this dimension. The data obtained is applicable to the engineering design of plastic films used in packaging applications. The effect of temperature is considered and heating of the plane to temperatures other than 23°C

Test apparatus

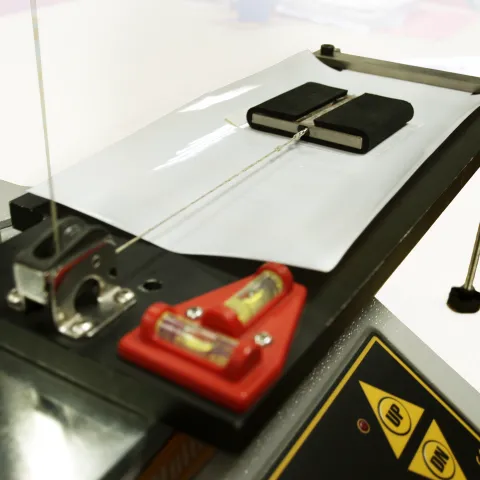

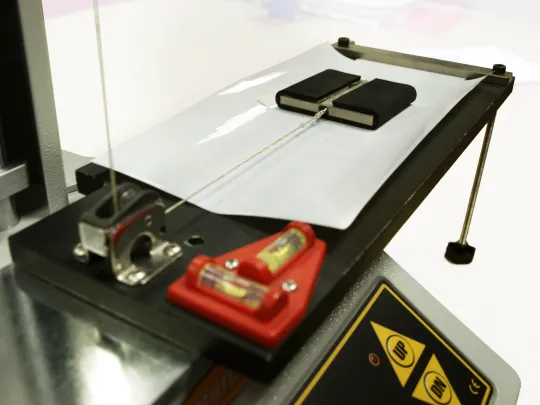

Mecmesin COF Tester.

ASTM D1894 sled

Elastic linkage for static coefficient of friction tests.

Rigid linkage for slip-stick control during kinetic coefficient of friction tests.

Emperor™ (Force) software.

Preparation

Cut the sample to be attached to the plane to 250 mm x 130 mm, usually in its machine direction and transverse direction respectively, to test. Sliding in the specimen’s machine direction. Attach securely via gripping.

The test piece to be attached to the sled is cut to 120 mm square if the specimen is defined as a film, and 63.5 mm square if defined as sheeting. Attach the samples to the sled with single-sided and double-sided tape respectively.

Take care not to contaminate the test pieces by handling or foreign matter and condition according to ASTM D618

Test method

ASTM D1894 determines the friction characteristics of the film sliding over itself or other substances. Several designs of apparatus are permitted

Attach the sled to the coefficient of friction tester crosshead. Allow time for stable temperature conditions to be achieved if conducting the test above 23°C.

Start the driving mechanism, set to a speed of 150 ± 30 mm/min (6.0 ± 1.2 in./min).

Record the initial maximum force reading, which is the static frictional force.

Once sliding has initiated, continue to run for at least another 130 mm and average the force, representing kinetic friction.

It may be necessary to record the static and kinetic friction forces in separate tests if stick-clip occurs, by using a rigid link between the sled and the tester crosshead.

Discard the samples and repeat the test until five valid sets of results are recorded.

Calculations

Calculate the coefficient of friction from the formula: µ = F/mg, where mg is the sled weight. Calculate the mean of the set of observations and the standard deviation.