Concept to consumer

Ensure the quality of your packaging through the supply chain, from evaluating raw and processed materials, components and complete products through to distribution.

PPT Group enables your business to engineer optimised and sustainable packaging solutions. The combined testing expertise from Alluris, James Heal, Lansmont and Mecmesin, delivers solutions for evaluating and assuring product integrity, quality, safety and efficacy.

Explore our specialist packaging testing microsite at PackagingTesters.com

消费者(第一方和第二方)和运输(第三方)包装测试解决方案

消费包装

我们生活在一个产品包装的世界中,最终用户的商品都以包装的保护形式提供,且设计必须易于开启。

大量的包装生产必须符合环境法规和减少浪费,同时适合用途。

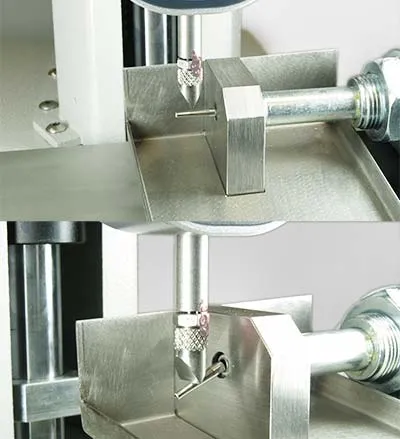

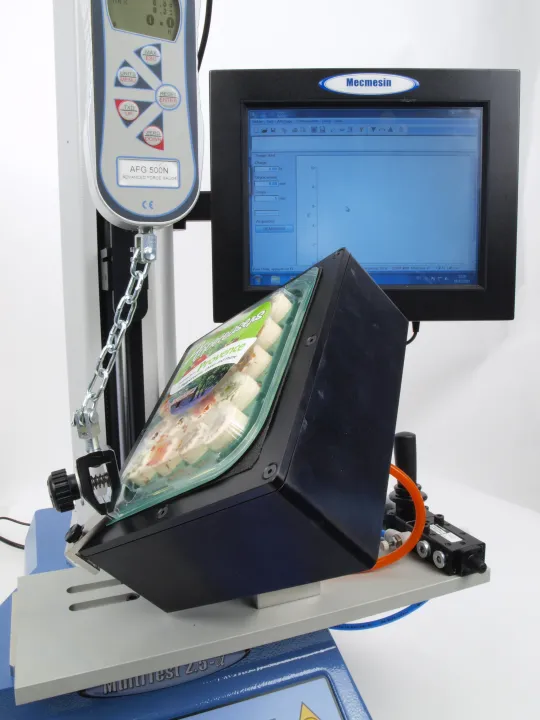

包装的抗穿刺性和打孔撕裂性能必须确保其密封性,同时易于打开。

药品包装设计必须最大程度密封内料,且用最小的剥离力撕开包装。

塑料瓶的某些部位设计需要一定的厚度,以确保灌装、封盖和存储过程中有着足够的强度和稳定性。顶压测试旨在测量塑料瓶的轴向强度,确保瓶子可承受一定的顶压力。

喷雾罐需要正确的手指压力来启动气雾剂,并且打开拉环时不得割伤手指。包装本身越具有美感,则固定和测试就越困难。

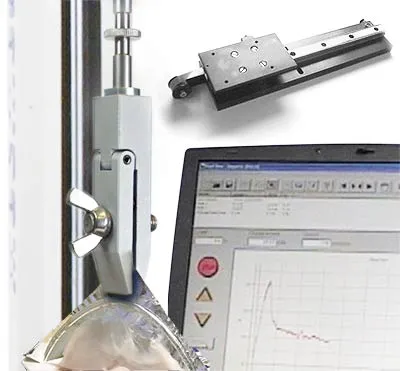

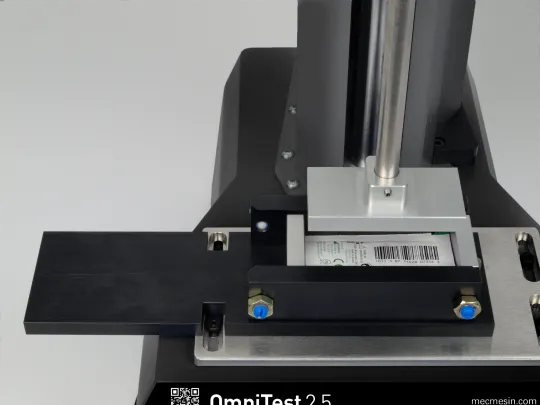

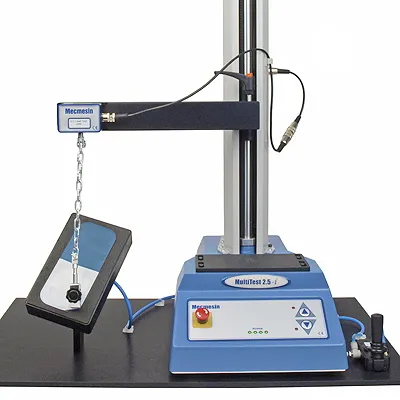

Mecmesin 设计各种包装产品的力学和扭矩系统以及固定工装,适用于研发实验室和生产车间的行业标准质量控制。

Emperor 控制和分析软件功能强大且灵活,只需按一下按钮即可进行可靠,准确,可重复的测试。

运输包装

运输包装制造商的目标是以最小的材料成本和重量提供足够的保护。

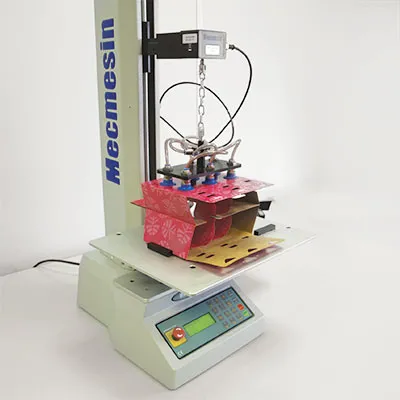

在应用的许多测试类型中,测试压板是关键。

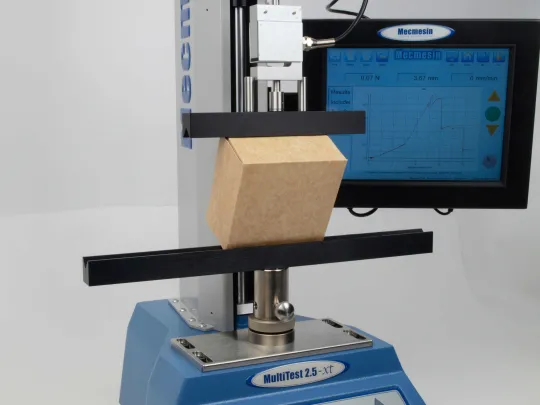

边缘,环形和平面压扁可以像整箱顶部负载一样预测强度,并且可以使用 Mecmesin 万能测试仪实现。

使用同一台机器对粘合剂,胶带和捆扎带以及摩擦,刚度,拉伸强度和抗刺穿性进行测试。

Mecmesin 测试仪满足 ASTM,BS EN,ISO,DIN,CEN,Afera,FEFCO,FINAT,PSTC,TAPPI,TLMI 测试方法和国际标准提供理想的解决方案。

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

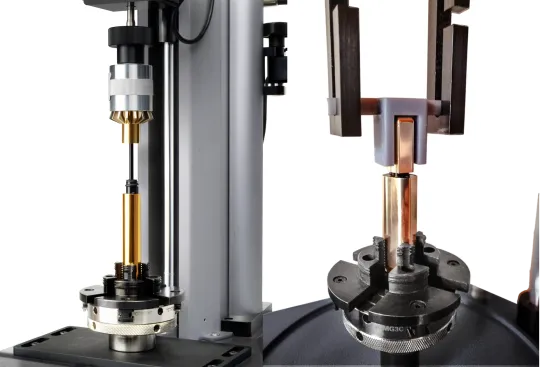

饮料和药品瓶盖的自动扭矩测试

拴式闭合器测试附着力

植物基聚乳酸材料瓶的顶部负载测试

Tamper-Proof Closure Test

瓦楞纸板的边缘抗压测试 (ECT)

酒罐可以突然撕开

封装塞子的粘合力测试

箱体压碎测试(BCT)和运输包装压缩测试

香槟和起泡葡萄酒软木塞提取力

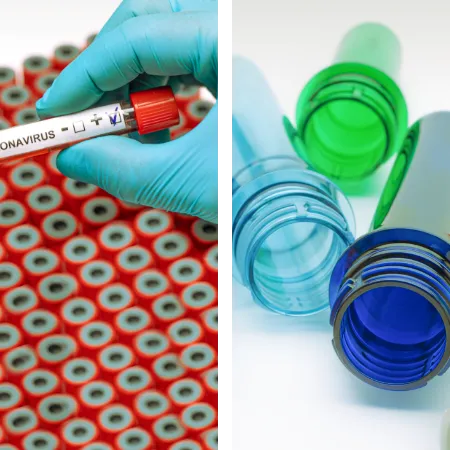

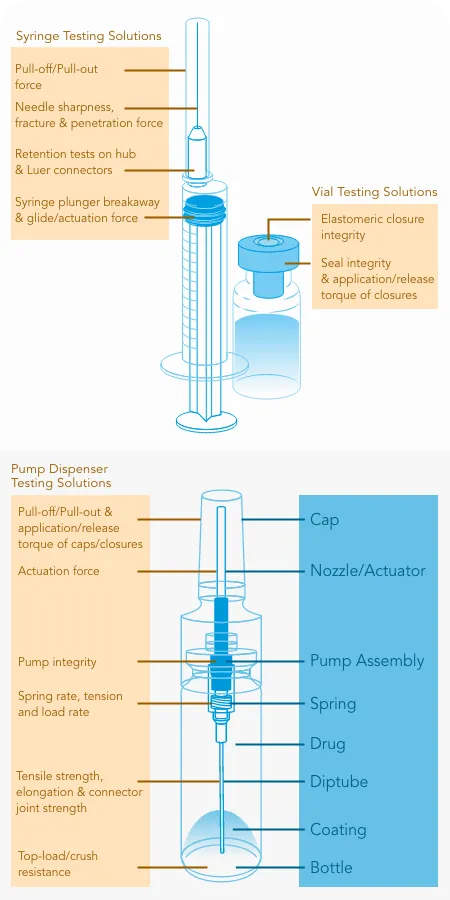

样品瓶:塞子针的渗透性,残余密封力和扭矩测试

通过气动向下的力对CRC密封件进行扭矩测试

PET屏幕保护膜释放衬垫剥离测试

COVID-19胶带和贴纸的粘合剥离强度

瓦楞纸板的边缘压碎测试(ECT)

PET 瓶坯 - COVID-19 测试试剂盒的生产

疫苗输送瓶和包装测试

益生菌饮料包装测试

口红管力和扭矩测试

多向塑料瓶的扭矩测试盖

金属瓶盖在玻璃拉拔试验上

药袋破裂强度

剥离测试真空成型容器

卫生垃圾箱封闭测试

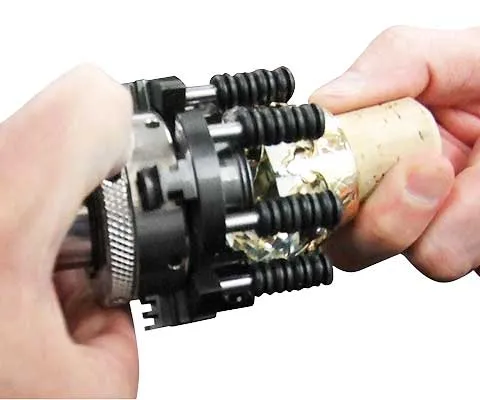

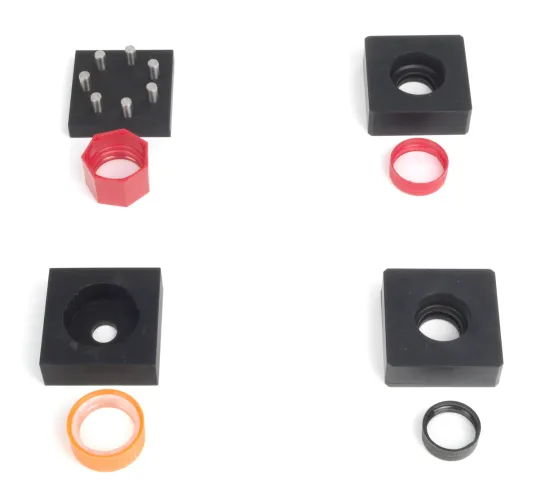

定制瓶盖夹头

防儿童闭合(CRC)心轴

粉状饮料容器-抗压强度和盖剥离测试

气动顶载控制,用于CRC盖扭矩测试

纸箱的成盒和压边强度

纸板饮料瓶托架展开

卡纸折痕线测试

散装液体载体封盖

茶包完整性

化妆品管翻盖附着强度

化妆品锡标签皮

医疗器械包装剥离测试

开式心轴用于闭合扭矩测试

蒸煮包装90度剥离和盖强度测试

旋转真空去皮系统

使用定制心轴进行瓶盖扭矩测试

冰淇淋包装封口和完整性测试

ISBT运动帽旋转测试

葡萄酒软木塞拔出测试符合ISO提取标准

壁挂式空气清新剂的破坏性负载评估

快餐托盘压碎测试

扭矩检测仪,适用于各种防盗盖

“挤压和扭动”儿童安全帽的去除扭矩

最高负荷测试PET瓶

塑料瓶的最高载荷压碎测试

指甲油封闭去除扭矩和封盖检查

胶膜张力测试

塑料样式的汽车流体容器陆地表面密封胶粘剂剥离

铝管密封件刺穿压缩力

铝盖喷嘴弯曲折断力

塑料瓶盖拆卸测试

工业流体容器分配帽的施加和移出力

聚乙烯薄膜拉伸测试

防拆环试验

医用袋热封接头拉伸试验

胶合纸板包装的完整性

翻盖力测试

软包装的焊接密封强度

DVD移除力测试

泵分配器的驱动力

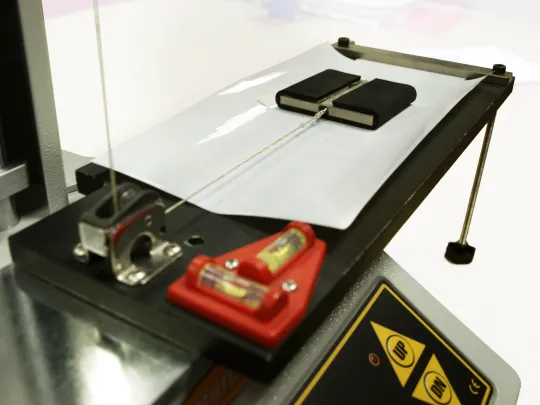

塑料薄膜的摩擦系数测试

闭合扭矩验证

种子瓶封闭扭矩测试

威士忌瓶塞的提取测试

香囊压缩试验

热成型塑料包装铰链撕裂和卡扣式啮合

ISBT运动封口张力测试

用扭矩拧出香槟软木塞

扭矩测试美容产品瓶盖

PET瓶的螺帽扭矩测试

泵分配器的螺杆扭矩

![抽吸夹具纸箱折叠测试,全开位置[PDV8017] 抽吸夹具纸箱折叠测试,全开位置[PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=EFU9vHec)

![压配合阀套[PDV14192] 压配合阀套[PDV14192]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1650-PDV14192-1-web.jpg.webp?itok=aZByb7MU)

![翻盖式拉扣[PDV13140] 翻盖式拉扣[PDV13140]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1685-PDV13140-web.jpg.webp?itok=WUckucX6)

![分体式瓶盖帽[PDV14075] 分体式瓶盖帽[PDV14075]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1761-PDV14075-web.jpg.webp?itok=-kBwMosn)