Concept to consumer

Ensure the quality of your packaging through the supply chain, from evaluating raw and processed materials, components and complete products through to distribution.

PPT Group enables your business to engineer optimised and sustainable packaging solutions. The combined testing expertise from Alluris, James Heal, Lansmont and Mecmesin, delivers solutions for evaluating and assuring product integrity, quality, safety and efficacy.

Explore our specialist packaging testing microsite at PackagingTesters.com

Soluções de teste da Mecmesin para embalagens de consumo (primária e secundária) e de trânsito (terciário).

Embalagem para consumidor

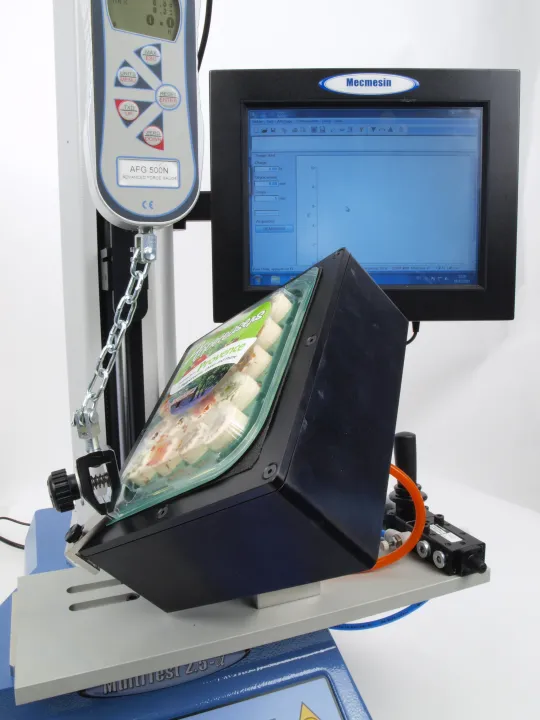

Vivemos em um mundo pré-embalado, onde a maioria dos bens do usuário final é fornecida em embalagens que protegem, mas que são projetadas para serem abertas facilmente.

Essa quantidade de embalagem e o crescimento da regulamentação ambiental criam pressão para produzi-la com o mínimo de desperdício e despesa, ao mesmo tempo em que são adequados para a finalidade.

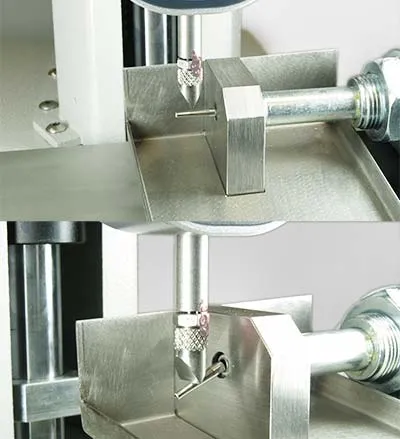

A resistência à perfuração é combinada com a perfuração pré-rasgo, fechamento de segurança com facilidade de abertura.

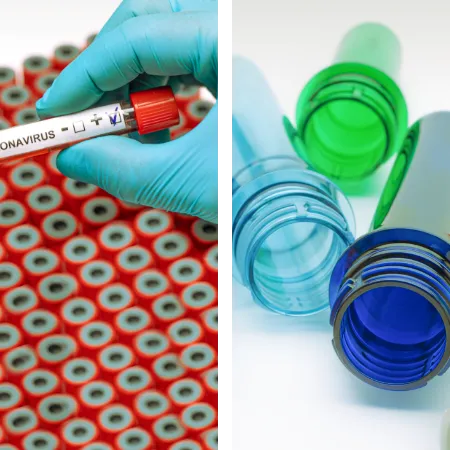

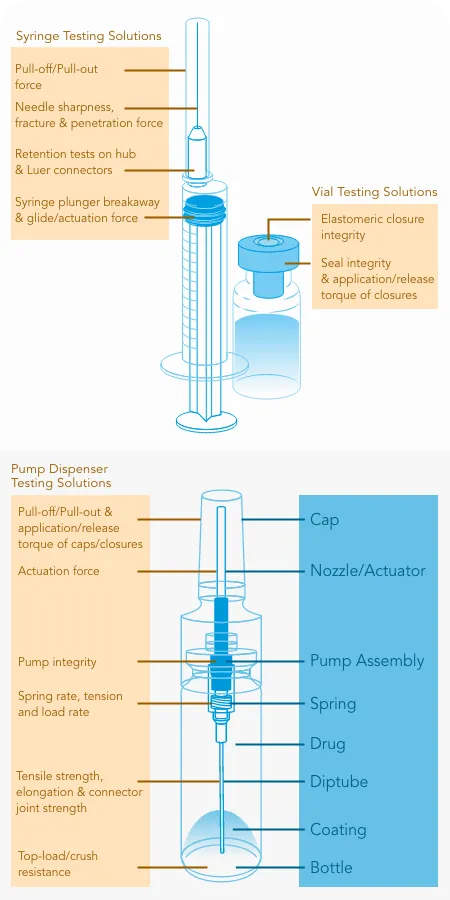

As embalagens farmacêuticas foram projetadas para vedação máxima e, ainda assim, casca mínima.

Garrafas de plástico exigem espessura para fornecer resistência e estabilidade durante os processos de enchimento, tampar e armazenamento, mas apenas nos locais da garrafa onde é essencial. O teste de força axial de carga máxima garante que as garrafas possam suportar tais forças.

As latas de spray requerem a pressão correta dos dedos para acionar o aerossol, e os puxadores de anéis não devem quebrar as unhas ou cortar os dedos quando abertos. Quanto mais a embalagem se torna estética, mais difícil pode ser agarrar e testar.

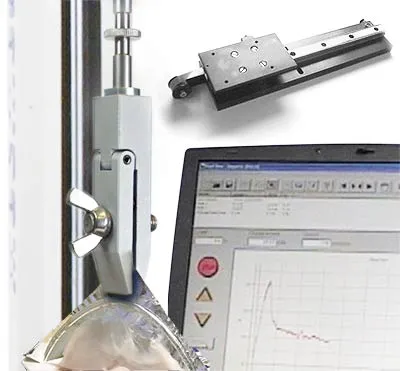

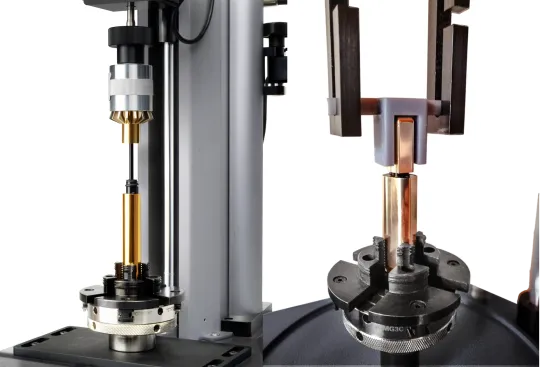

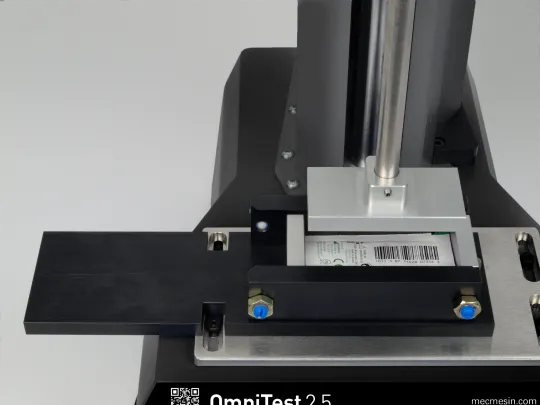

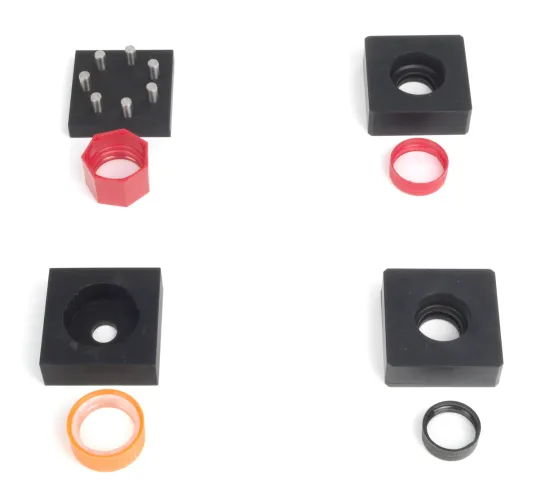

Na Mecmesin, projetamos sistemas de força e torque e acessórios para embalagens de todos os tipos, para que você possa aplicar métodos de teste padrão da indústria em ambos os projetos e no chão de produção para controle de qualidade.

Nosso software de controle e análise Emperor é poderoso e flexível para testes confiáveis, precisos e repetíveis com o pressionar de um botão.

Embalagem de trânsito

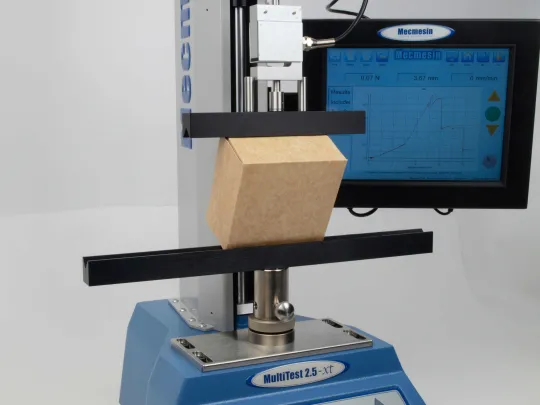

O objetivo dos fabricantes de embalagens de transporte público é fornecer proteção adequada a um custo e peso mínimos de materiais.

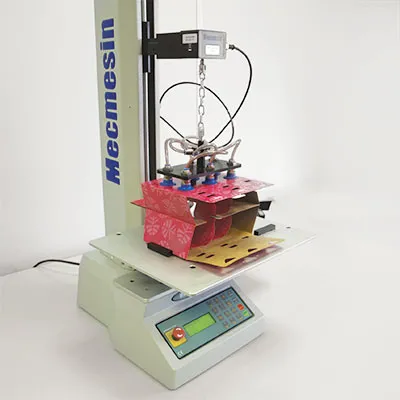

Dos muitos tipos de teste aplicados, as amostras da placa de teste são centrais.

A borda, o anel e a trituração plana podem ser tão preditivos de resistência quanto a carga máxima da caixa inteira e podem ser alcançados usando um testador universal Mecmesin.

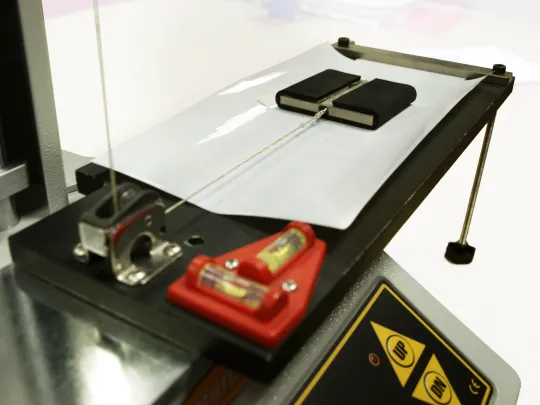

Testes de adesivos, fitas adesivas e cintas, bem como atrito, rigidez, resistência à tração e resistência à perfuração podem ser realizados usando as mesmas máquinas.

Os testadores Mecmesin fornecem uma solução ideal para atender aos padrões e métodos de teste corporativos da ASTM, BS EN, ISO, DIN, CEN, Afera, FEFCO, FINAT, PSTC, TAPPI, TLMI, etc.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Teste da força de fixação dos fechos com fio

Tamper-Proof Closure Test

Teste de adesivo em rolhas encapsuladas

Teste de embalagem de bebida probiótica

Teste de força e torque do tubo de batom

Força de ruptura de sachê farmacêutico

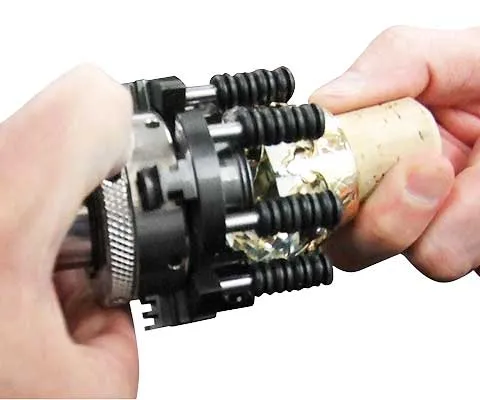

Mandris de tampa de garrafa personalizados

Teste de linha de vinco de cartão e papel

Tampas de líquido a granel

Integridade do saquinho de chá

Casca de rótulo de lata de cosméticos

Sistema Rotativo de Peeling a Vácuo

Teste de rotação de boné esportivo ISBT

Fast food tray crush testing

Top-load testing PET bottles

Top-load crush test of plastic bottles

Teste de tensão de filme plástico

Recipiente de fluido de motor em estilo plástico com casca adesiva de vedação de superfície

Teste de tração em filme de polietileno

Teste de toque com evidência de violação

Integridade da embalagem de papelão colado

Teste de força flip-cap

Teste de força de remoção de DVD

Força de atuação do distribuidor da bomba

Validação de torque de fechamento

Teste de extração de rolhas de uísque

![Teste de dobra da caixa de fixação de sucção, posição totalmente aberta [PDV8017] Teste de dobra da caixa de fixação de sucção, posição totalmente aberta [PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=EFU9vHec)

![Colares de válvula press-fit [PDV14192] Colares de válvula press-fit [PDV14192]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1650-PDV14192-1-web.jpg.webp?itok=aZByb7MU)

![Flip cap pull-off [PDV13140] Flip cap pull-off [PDV13140]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1685-PDV13140-web.jpg.webp?itok=WUckucX6)

![Alças de remoção semirrígidas [PDV13194]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1671-vacuum-peel-system-web.jpg.webp?itok=6ukLBDXB)

![Mandril dividido para tampa do frasco [PDV14075] Mandril dividido para tampa do frasco [PDV14075]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-04/1761-PDV14075-web.jpg.webp?itok=-kBwMosn)