The pharmaceutical industry is tightly controlled and subject to strict regulations, which means that testing is often at the heart of demonstrating compliance to the various international standards which govern the industry. Stringent performance and safety-critical criteria must be met to operate and produce successfully.

Where testing the mechanical strength characteristics of products and activities is related to the pharmaceutical industry, it can be broadly summarised under three groups - Medical devices, Pharmaceutical packaging, and Pharmaceutical products.

Medical Devices

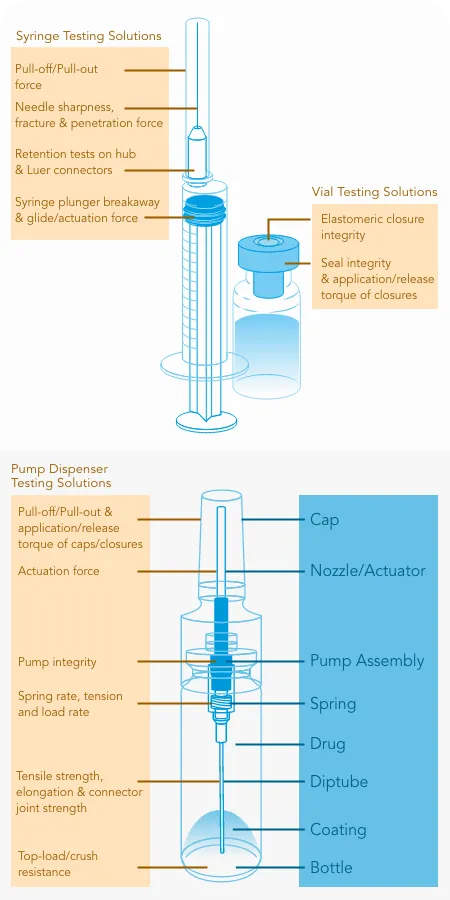

Drug delivery systems have evolved by using self-regulated and nano-technology systems to administer drugs to specific localised target sites, which would otherwise be difficult to reach. The effectiveness of treatment can depend significantly on the mechanical performance of medical devices with increasing emphasis being placed on devices which are user-friendly, intuitive to use, and also increase patient comfort.

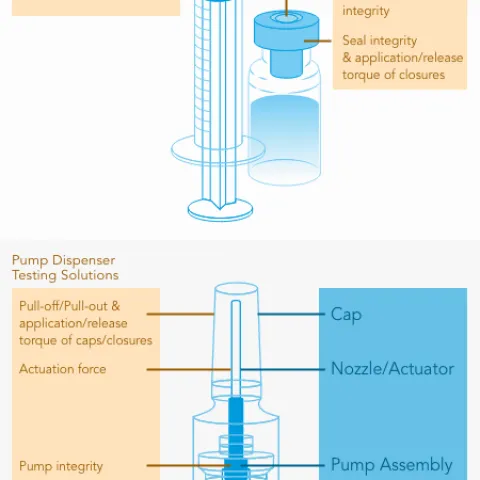

The frictional glide force of pre-filled syringes, the insertion and connection force of catheter tube systems, the sharpness of cannulae needle systems ... a huge number of applications for tensile, compression and torque testing are covered in our dedicated Medical Devices section.

Pharmaceutical Packaging

The packaging is an integral part of all pharmaceutical products. It is often involved in dispensing, dosing, and use of the pharmaceutical product and needs to assure patient safety as well as the efficacy of the drug over its intended shelf life.

Testing the push-out force of pills from non-reclosable packaging, such as blister packs, ensures they meet the criteria to prevent children from accessing harmful products.

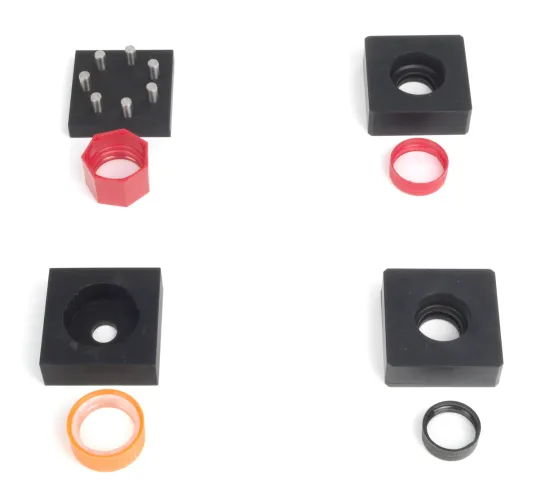

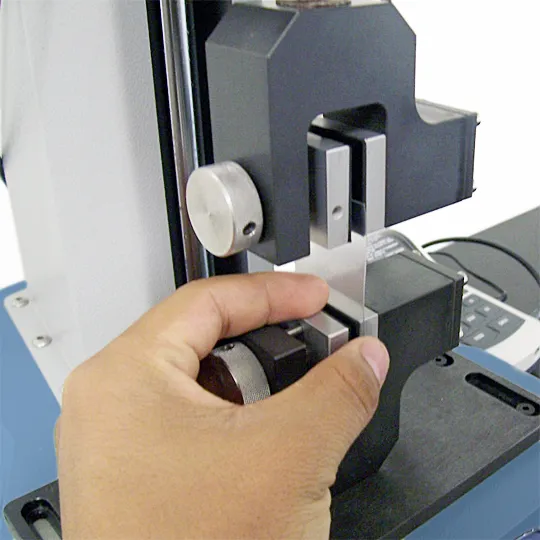

Testing the push-and-twist torque of a CRC (child-resistant closure) screwed to reclosable containers is fundamental to child safety but also assures the frail and elderly can still access medication.

Testing the seam strength of tubes containing drugs and ointments ensures they don't split or burst during normal use.

Testing the de-lamination peel strength of packaging containing transdermal patches ensures it is strong enough to keep the contents sterile.

Pharmaceutical Products

Tablets are formed by compressing powder granules into a solid dose form and tablet hardness is an important control parameter as it affects the key properties of disintegration, dissolution and friability.;

By compression testing of the breaking point and structural integrity of a tablet under conditions of storage, transportation, and handling before use, a manufacturer can learn valuable information to help adjust the manufacturing process to achieve the desired results.

You might be a pharmaceutical manufacturer or a supplier of components, sub-assemblies or packaging. In all cases, your reputation depends on compliance with industry standards, internal specifications and customer expectations at every level.

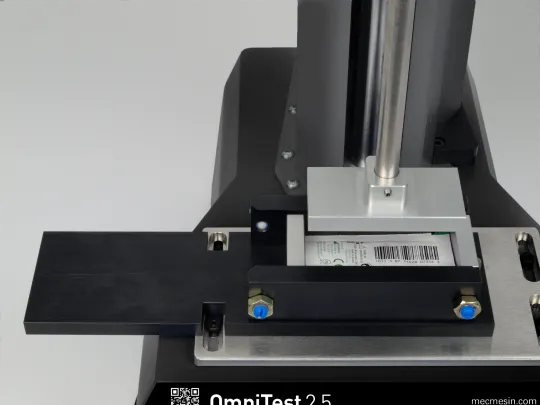

Force, materials and torque test equipment from Mecmesin offer you versatile, practical solutions to your quality-control requirements at an attractive price. We have over 40 years of experience in delivering test solutions to the pharmaceutical industry.

Mecmesin testing solutions are used by leading pharmaceutical, nutraceutical and medical device manufacturers across the world. We understand your industry-specific requirements whether it be IQ/OQ/PQ or FDA 21 CFR Part 11.

Test to ASTM, EN, ISO, DIN, US and European Pharmacopoeia standards.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Syringe plunger breakaway and glide force

Pharmaceutical sachet burst strength

Child resistant closures (CRC) mandrel

Syringe pump calibrator

Elongation test of infusion solution bag

End float test of inhaler cap

Screw torque of pump dispensers

Medical Devices industry brochure

Safety requirements for medical devices and pharmaceuticals are paramount as they are predominantly used on humans. This puts a heavy emphasis on quality control during development, production and packaging.

Download our latest industry brochure for medical device force and torque testing solutions.