Globally many manufacturers of plastics and rubber materials, components and finished products use Mecmesin test equipment to ensure their quality, strength, performance and usability.

Our test solutions for the plastic and rubber industry include:

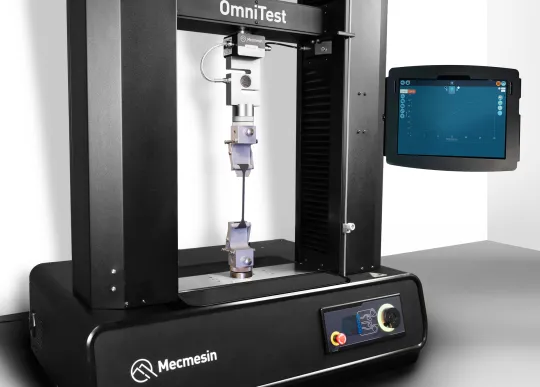

- 3-point bend testing to identify flexural properties of plastics

- adhesion/peel testing of plastic labels, ID and credit cards

- coefficient of friction testing of plastic film and sheeting

- compression testing of plastic foam

- measuring the elongation/return characteristics of plastics, rubber and elastomers

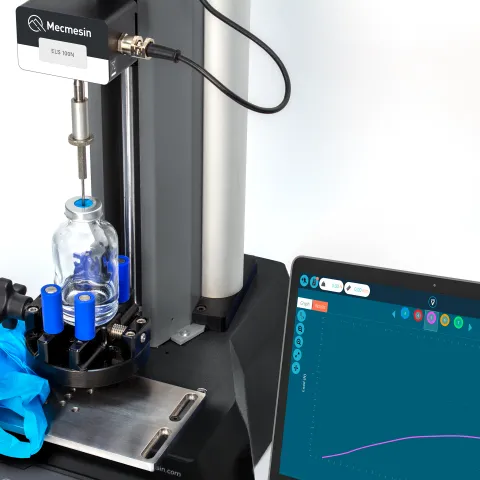

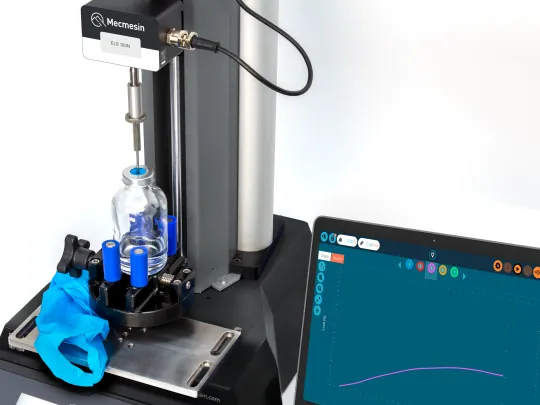

- measuring the initial 'slip' torque and 'bridge' torque on plastic tamper-evident closures

- pull-off and insertion/withdrawal testing of plastic fasteners

- release and application torque of plastic closures

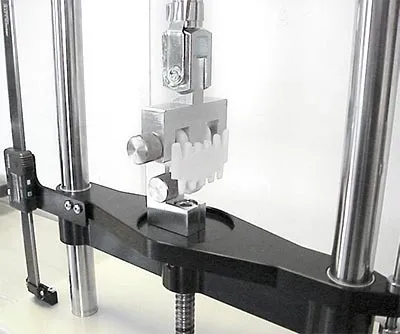

- tensile and material strength testing of:

- conveyor belts

- gaskets and o-rings

- rubber and plastic flooring

- shoe soles

- tyres

- top-load testing of plastic containers, e.g. PET bottles

Achieve regulatory compliance, test to a range of international standards, e.g. ASTM, BS, DIN or in-house specifications.

We have over 40 years of experience in solving quality-control challenges for the plastics and rubber industry.

Our force, materials and torque test equipment offer you versatile, practical solutions to your quality control requirements at an attractive price.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Testing rubber to materials standards

Tamper-Proof Closure Test

Fast food tray crush testing

Top-load crush test of plastic bottles

Peel testing identity cards

Plastic film tension test

Plastic chain conveyor tensile strength test

Automotive external mirror deformation tests

Car window sliding force tester

Tensile testing on polyethylene film

Tensile test on rubber gaskets

Surfboard foam three-point bend test

Actuation force of pump dispenser

Detonator shock tubing

PVC pipe valve actuation torque