Search results

376

Event

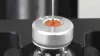

Medical Device Testing: Needle sharpness and syringe actuation testing (with 21 CFR Part 11 compliance)

Hypodermic needles are tested to determine their efficacy in piercing elastomer closures on vials and how their design influences the ease of insertion into the patient's skin, influencing pain and skin trauma.

The smooth and consistent operat

377

[Page extract]

ISO 527-5

ISO 527-5 specifies the test conditions for the determination of the tensile properties of unidirectional fibre-reinforced plastic composites, based upon the general principles given in ISO 527-1.

378

Case study

Automotive window winder turning effort

Requirement

The customer requested a portable system which would quickly and easily allow him to test the torque required to open and close windows in a car.

379

Event

Needle Sharpness & Puncture Resistance Testing

Hypodermic needles are tested to determine how their design influences the ease of insertion into the skin in order to prevent patient pain and skin trauma.

380

[Page extract]

ASTM D2062

The method(s) in the standard along with those in Test Methods D 2051, D 2052, D 2053, D 2054, D 2057, D 2058, D 2059, D 2060, and D 2061 are a collection of proven test methods.

382

Case study

Adjustable spectacles

Requirement

Adlens manufacture adaptive lenses used within spectacles that are distributed throughout the world. The lenses change power at the turn of the dial located at the side of the spectacle.

383

Case study

Industrial fixtures and fasteners

Requirement

SFS intec is a global supplier of precision components, special fasteners and mechanical fastening elements, with long-standing customer relationships, in the aerospace, automotive and construction industries.

384

Event

Needle Sharpness & Puncture Resistance Testing

Hypodermic needles are tested to determine how their design influences the ease of insertion into the skin, patient pain and skin trauma.

385

Event

Needle Sharpness & Puncture Resistance Testing

Hypodermic needles are tested to determine how their design influences the ease of insertion into the skin in order to prevent patient pain and skin trauma.

386

Case study

Pen injector training aid testing

Requirement

Crux Product Design is an innovative design agency which sees products through from a creative idea to production reality.

387

Event

Materials Testing: Theory and Practice Pt. 1 & 2

Materials testing is often the last step in the manufacturing process. Yet, quality is the result of both the process and the material. If the material that goes into the product is inadequate or defective, then the product may be deficient or faulty.

388

[Page extract]

ASTM D2061

No one test determines the suitability of a zipper for a specific end use. Since the tests are inter-related more than one may be needed for a complete evaluation.

389

[Page extract]

ASTM D2731

ASTM D2731 is a test method for determining the elastic properties of elastomeric yarns made from rubber, spandex or other elastomers. Elastic properties include force at specified elongations, permanent deformation and stress decay.

390

Case study

Top-load Testing of Plant-based PLA Material Bottles

Requirement

BioPak Solutions in Roquefort-les-Pins, France, are leaders in the production of Polylactic Acid (PLA) bottles. The bottles are oil-free, contain no PET or Bisphenol A, and are made 100% from carbon-absorbing plants.

391

Case study

Cost effective cable strength testing

Customised engineering example

A major manufacturer of wire harnesses and connectors approached us for a cost-effective solution to pull-force test cables with different diameters having direct-bonded joints.

392

Case study

Metal bottle cap on glass pull-off test

Customised engineering example

Gripping the base of a glass bottle for a tensile test can be challenging due to the slippy surface and contoured shape.

393

Case study

Press stud popper pull-off test

Requirement

The customer was a supplier to major clothing retailer Marks & Spencer, who stipulate that all fasteners and attachments must be tested to failure.

394

Case study

Peel testing identity cards

Requirement

The customer produces identity cards with a laminated cover. The customer wanted to know that the adhesive used to bond the laminate and card together was strong enough to withstand a high rate of day-to-day usage.

395

[Page extract]

Test type

Mecmesin provides solutions for tests on products or materials that require the measurement of their physical strength. Typically this involves applying and recording the force to pull apart, push together, twist or turn.

396

[Page extract]

ASTM D7257-06

This test method of applying force may be used as a standard test to compare the characteristics of a given design of container/child-resistant closure system with a standard or to compare the characteristics of container/child resistant closure systems

397

Case study

Sachet compression test

Requirement

To compress six sachets of ketchup or mayonnaise until failure of the packaging occurred.

The peak compressive force was required as the test result.

398

[Page extract]

BS EN ISO 12230

This European Standard specifies a method for the determination of the tensile properties of materials used as surfaces for sports areas.

399

Case study

Luer lock fastening and release torque

Customised engineering example

Luer lock test standards frequently call for measuring torque whilst simultaneously applying a pre-defined axial force.

400

Case study

Cricket ball compressive deformation strength and cover material tensile strength

Requirement

Kookaburra is an internationally recognised leader in the production of sporting equipment for cricket and hockey. Established in 1890, the company has built its name on innovation and meticulous attention to quality.