Search results

1126

Bundle

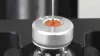

Top-load PET bottle CSD non-vented

OmniTest 2.5

BD

Top-load testing (also known as 'column-crush' and 'axial force resistance') is performed mainly on blow moulded, thermoformed or injection moulded plastic containers such as PET (Polyethylene terephthalate) bottles.

1127

Case study

Closure torque validation

Requirement

The customer had a number of Tornado closure torque testers, and wished to carry out regular validation checks without the need to return the units to either Mecmesin or an approved laboratory.

1128

Case study

Filter test station

Requirement

The following tests were required in a simple-to-use system for a series of tests on automotive filters:

1129

[Page extract]

Key test standards for ball burst testing

ASTM D3787 – Constant-rate-of-traverse (CRT) method

This standard outlines a method for determining the bursting strength of

1130

Case study

Cable duct strength testing

Customised engineering example

Our customer manufactures tubes and ducts for routing of cables and optical fibres. Installation of these uses blowing, pushing and pulling techniques.

1131

Case study

Glass syringe Luer lock attachment pull-off

Customised engineering example

Polycarbonate Luer Lock adapters are push-fitted to glass syringe nozzles with a friction fit. Quality assurance demands that they cannot come free under normal use.

1132

[Page extract]

Built for batch testing and automation

Batch testing in VectorPro uses a pre-configured test to create a semi-automatic or fully automatic testing system on sets of products and batches of the products.

1133

[Page extract]

ASTM D1710

Among tests for electrical and dimensional (temperature) stability, includes methods for tensile characteristics.

1134

Case study

Portabottiglie per bevande in cartone aperto

Esempio di ingegneria personalizzato Un produttore di cartoni completamente chiusi voleva testare la qualità della forza pieghevole per una varietà di modelli, utilizzati principalmente per confezionare bottiglie di bevande e lattine.

1135

Event

Tensile Testing: Basics, Tips, & Trends

Have you ever wondered if the seatbelt in your vehicle is strong enough to restrain you in a collision? How about the average person pulling the cork out of a wine bottle?

1136

[Page extract]

ASTM E9-09

These test methods cover the apparatus, specimens, and procedure for axial-load compression testing of metallic materials at room temperature.

1137

[Page extract]

Tensile deformation and its significance

Tensile deformation occurs when a material is stretched by an axial load, causing it to elongate.

1138

[Page extract]

Importance of testing elasticity and ultimate strength

Elasticity determines how well a material returns to its original shape after stretching. Ultimate strength indicates the maximum stress it can withstand before failure.

1139

[Page extract]

BS EN 60794-1-21:2015+A1

This part of IEC 60794 applies to optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and to cables having a combination of both optical fibres and electrical conductors.

1140

[Page extract]

ASTM D412-16

ASTM D412 is a test standard for testing the tensile stress-strain properties of thermoset rubbers and thermoplastic elastomers. The standard is divided into two test methods.

1141

[Page extract]

Simplify data analysis in force, materials and torque testing

Test calculations are the values derived from raw measurement data, such as peak force, torque angle, or modulus of elasticity. With advanced software, these are now calculated instantly and with high precision, replacing error-prone manual methods.

1142

[Page extract]

Introduction to penetration and puncture resistance testing

Penetration and puncture resistance testing are essential for evaluating how well a material can withstand force from sharp, pointed, or blunt objects.

1143

Case study

Adjustable spectacles torque test

Customised engineering example

Adlens manufacture adaptive spectacle lenses, where the optical power is adjusted by a side dial which is then removed.

1144

[Page extract]

Standards for the 90-degree peel test

The 90-degree peel test is defined by several recognised international standards, which provide consistent methodology and reporting requirements:

1145

[Page extract]

ISO 13939

Describes a method of comparing the performance test results of foil journal bearings, which are lubricated by air (gas) and supported by hydrodynamic force generated by the rotation of the rotating shaft.

1146

Case study

Taglio a saldare PCB

Requisiti Millennnium Microtech Thailand, parte di Microchip Technology Inc Thailand, gestisce un impianto di produzione, confezionamento e collaudo di componenti per circuiti integrati (IC).

1147

Case study

Test di carico dall'alto bottiglie in PET

Requisiti

Esterform Packaging produce oltre un milione di bottiglie e preforme in PET al giorno per i principali trasformatori di acqua in bottiglia, succhi di frutta, bibite, latticini e prodotti per la casa.

1148

Event

Needle Sharpness & Puncture Resistance Testing

Hypodermic needles are tested to determine how their design influences the ease of insertion into the skin, patient pain and skin trauma.

1149

[Page extract]

Standards for tear resistance testing

While the core principle of wing tear testing remains the same, each standard specifies unique specimen shapes, notch sizes and test speeds. Adhering to these requirements ensures results are valid and comparable.

1150

Event

Needle Sharpness & Puncture Resistance Testing

Hypodermic needles are tested to determine how their design influences the ease of insertion into the skin in order to prevent patient pain and skin trauma.