Search results

Globalmente, muitos fabricantes de materiais plásticos e de borracha, componentes e produtos acabados usam equipamentos de teste Mecmesin para garantir sua qualidade, resistência, desempenho e usabilidade.

Nossas soluções de teste para a indústria de plástico e borracha incluem:

- Teste de flexão de 3 pontos para identificar propriedades de flexão de plásticos

- teste de aderência / remoção de etiquetas plásticas, cartões de identificação e de crédito

- teste de coeficiente de atrito de filme plástico e folhas

- teste de compressão de espuma plástica

- medição das características de alongamento / retorno de plásticos, borracha e elastômeros

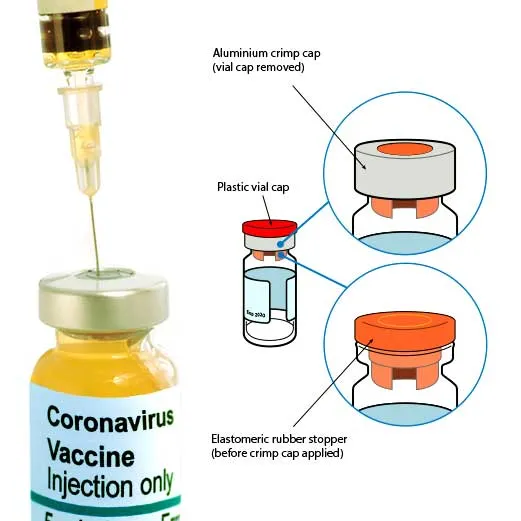

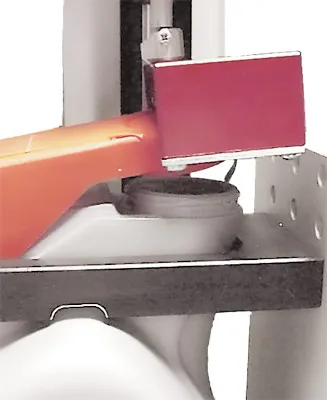

- medir o torque inicial 'slip' e o torque 'bridge' em tampas invioláveis de plástico

- testes de arranque e inserção / retirada de elementos de fixação de plástico

- torque de liberação e aplicação de tampas de plástico

- ensaios de resistência à tração e ao material de:

- correias transportadoras

- juntas e O-rings

- piso de borracha e plástico

- solas de sapato

- pneus

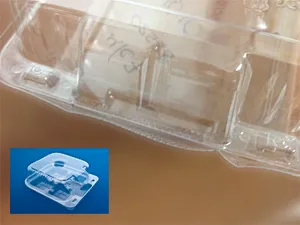

- teste de carga máxima de recipientes de plástico, por exemplo, garrafas PET

Obtenha conformidade regulamentar, teste com uma variedade de padrões internacionais, por exemplo, ASTM, BS, DIN ou especificações internas.

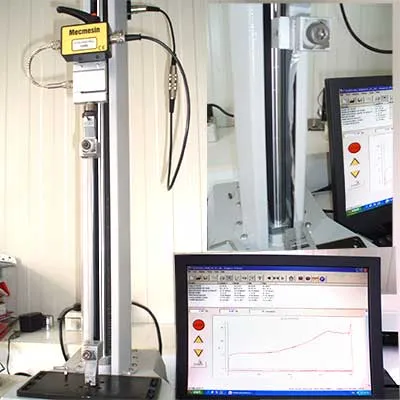

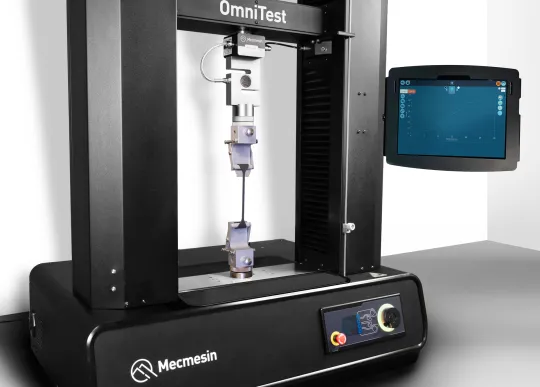

Nossos equipamentos de teste de força, materiais e torque oferecem soluções práticas e versáteis para os seus requisitos de controle de qualidade a um preço atraente. Temos mais de 40 anos de experiência na solução de desafios de controle de qualidade para a indústria de plásticos e borracha.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Testing rubber to materials standards

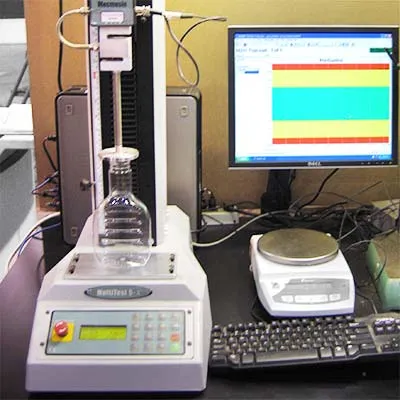

Tamper-Proof Closure Test

Fast food tray crush testing

Top-load crush test of plastic bottles

Peel testing identity cards

Teste de tensão de filme plástico

Recipiente de fluido de motor em estilo plástico com casca adesiva de vedação de superfície

Teste de tração em filme de polietileno

Teste de tração em juntas de borracha