A engenharia automotiva é uma área complexa que incorpora elementos de engenharia mecânica, elétrica, de software e de segurança. Desempenho rigoroso e critérios críticos de segurança devem ser atendidos para produzir veículos bem-sucedidos.

Você pode ser um fornecedor de componentes, submontagens ou peças de reposição ou um fabricante de marca OEM. Em todos os casos, sua reputação depende da conformidade com os padrões do setor, especificações internas e expectativas dos clientes em todos os níveis.

Os sub-sistemas automotivos de trem de força, chassi, elétrico, de acabamento e auxiliar geralmente requerem procedimentos de teste complexos.

Nossas soluções de teste específicas do setor para clientes do setor automotivo incluem:

- esforços ergonômicos envolvidos na abertura, fechamento e ajuste de portas, janelas e outras arquiteturas

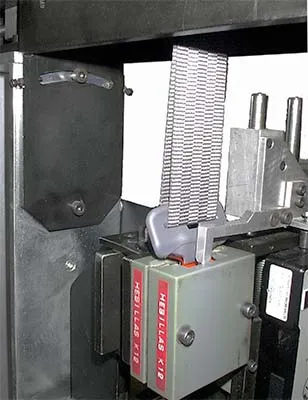

- forças que definem o desempenho dos componentes do sistema elétrico

- torque para acionar os controles rotativos

- forças para acionar os botões do painel

- propriedades de compressão e tração de molas

- resistência dos componentes flexíveis de plástico e borracha

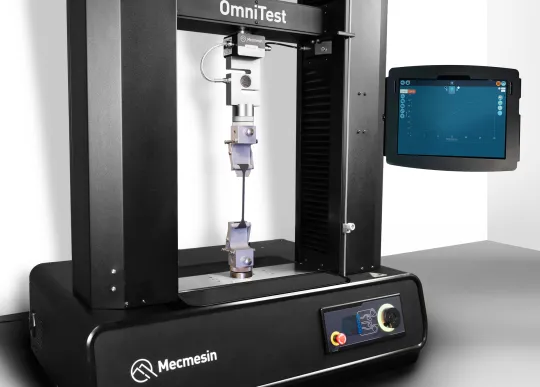

A medição rápida e precisa com equipamentos confiáveis de teste de força e torque é essencial para controlar a resistência mecânica e a qualidade de seus produtos, garantindo a segurança e a percepção da marca.

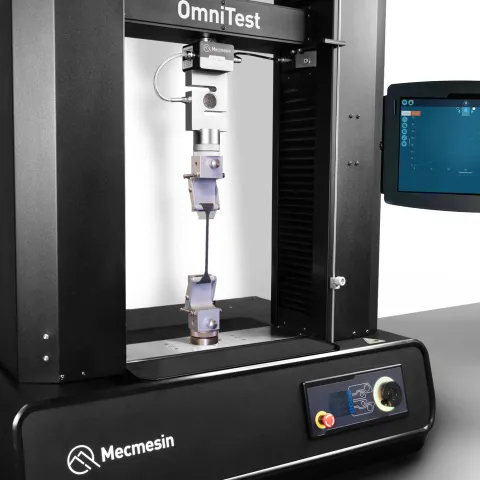

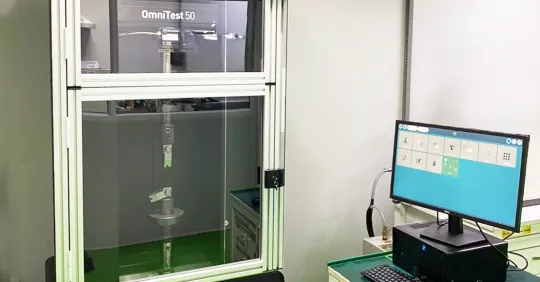

As soluções de teste da Mecmesin são usadas pelos principais fabricantes e empresas de engenharia em todo o mundo, seja nos níveis de componente, montagem ou construção completa.

Teste para ASTM, BS EN, ISO, DEF, DIN, CEN, MIL, VDI

Temos também uma vasta experiência no setor mais geral da indústria de transportes .

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Teste de força solenóide

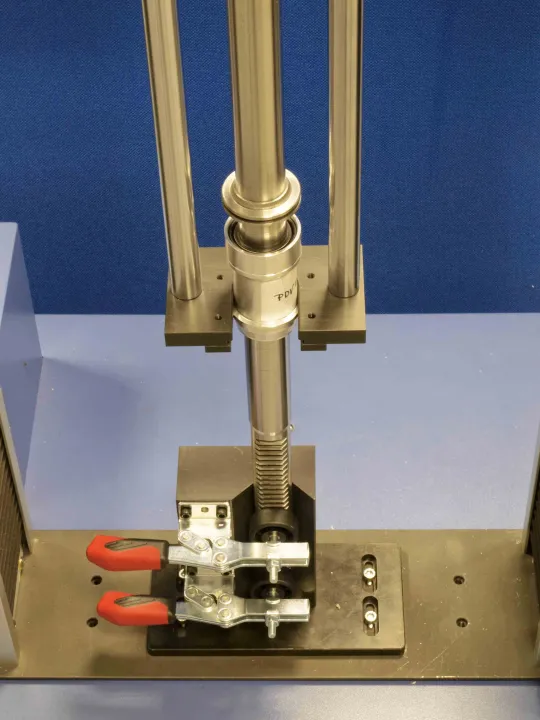

Componentes de direção automotiva

Motorcycle switchgear actuation forces

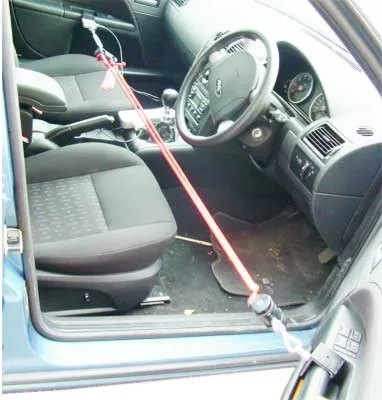

Esforço de fechamento da porta do carro

Teste de tração em juntas de borracha

Acessórios e fixadores industriais

Estação de teste de filtro

Teste de terminal de chicote elétrico