Marine engineering is an area incorporating elements of mechanical, electrical, software and safety engineering for sailboats, tankers, submarines and other marine vessels. Stringent performance and safety-critical criteria must be met to operate and produce successful vessels.

You might be a supplier of components, sub-assemblies or replacement parts used on marine vessels. In all cases, your reputation depends on compliance with industry standards, internal specifications and customer expectations at every level.

Our customers from the marine industry use our test solutions for a wide range of quality-control testing applications including testing:

- pull-off strength of terminals for welded and crimped joints on marine cables

- insertion/withdrawal forces of electrical connectors

- tensile strength of riveted metal joints

- tensile strength of underwater lift bags

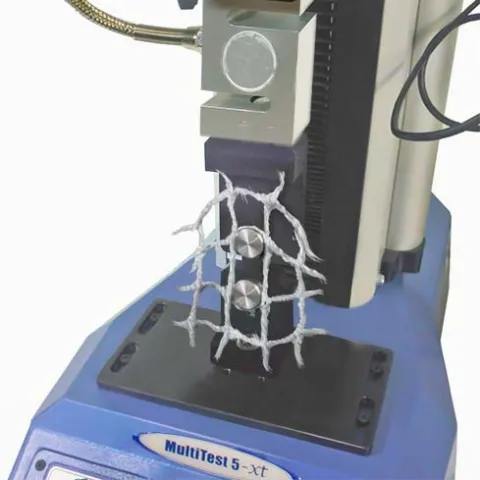

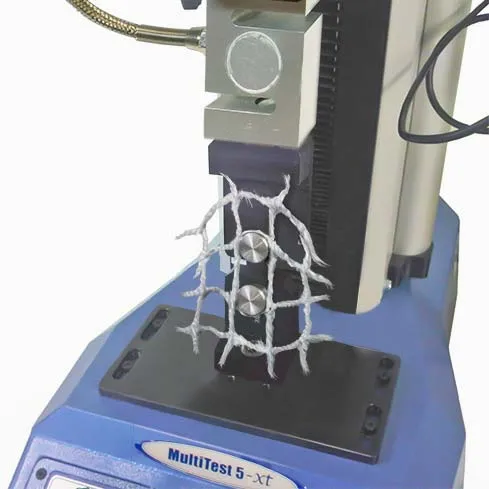

- tensile strength of fishing nets

- actuation force of switches on emergency beacons, tracking and monitoring devices

- torque to actuate rotary controls

- compression and tensile properties of springs

- load characteristics of small motors

- shear and tensile strength of fasteners

- peel strength of composite materials used in vessels

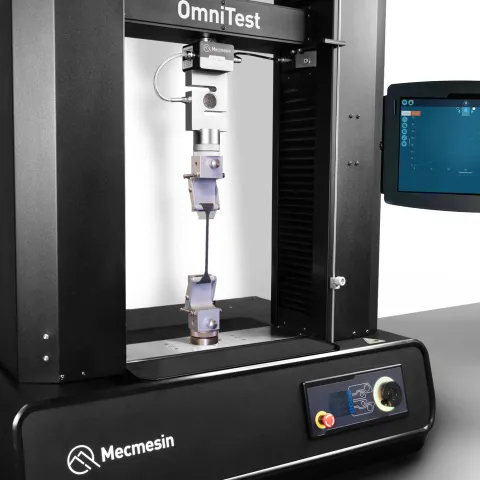

Force, materials and torque test equipment from Mecmesin offer you versatile, practical solutions to your quality control requirements at an attractive price. We have over 40 years of experience in delivering test solutions to the defence industry.

Mecmesin testing solutions are used by leading manufacturers and engineering companies across the world, whether it be at the component, assembly or full-build levels.

Test to ASTM, BS EN, ISO, DEF, DIN, CEN, MIL standards.

We also have a wealth of experience in the more general transport industry sector.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Fishing line and knot strength

Tensile test on rubber gaskets