Mecmesin 长期以来一直为能源行业的供应商和承包商提供力学和扭矩测试解决方案。跨国和海底油气,水和煤气管道的老牌制造商需要对管道进行压缩和拉伸测试,作为涂层质量检测的一部分。对连接器,阀门和歧管进行测试,确保其物理强度足以应付恶劣的环境条件。使用焊接或焊接端子的电子连接器需要测试抗拉强度。

太阳能

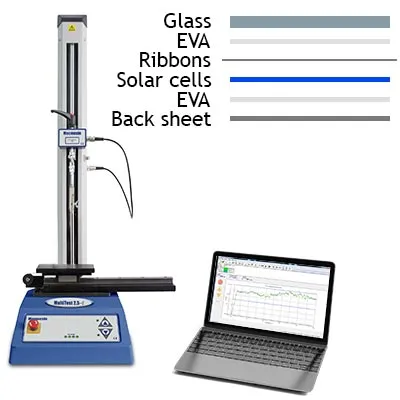

光伏(PV)太阳能电池板是一种复杂的“多层板”,由不同层的高级材料组成。薄膜(TF)太阳能电池是通过在基板(例如玻璃,塑料或金属)上沉积光伏薄膜的薄层(例如Tedlar®)制成的,然后将这些电池装配到刚性或半柔性面板上。这些PV太阳能电池板的有效性能取决于许多因素,包括在极端环境下承受力学损坏的能力。

因此,力学强度测试是以下方面的初始和持续质量控制检查的关键部分:

- EVA 与玻璃,薄膜或PET初始粘合时的粘合强度-方法:90°或180°剥离测试

- 暴露在极端温度和湿度下后的粘合强度保持率,作为重新认证测试的一部分-方法:90°或180°剥离测试

- PV 接线盒中使用的MC4连接器和电缆的抗拉强度

- 光伏组件框架的组装强度,以确保可以承受承重要求

- 玻璃的穿刺强度和弯曲强度

达到法规要求,测试一系列国际标准,例如ASTM,BS,DIN或内部规范。

我们的力学,材料和扭矩测试仪器价格实惠,为您提供满足质量控制要求的多功能实用解决方案。我们在解决能源行业的质量控制挑战方面拥有40多年的专业经验。

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Case study

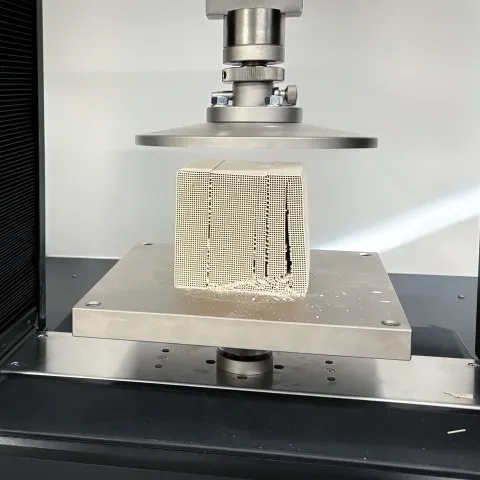

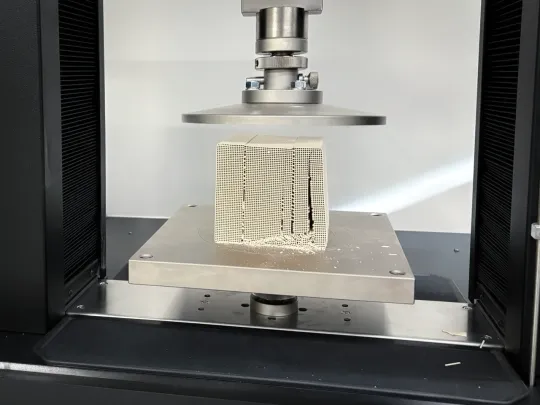

催化剂颗粒的抗压强度测试

Case study

测试流体控制阀和密封件

Case study

矿棉隔热板测试

Case study

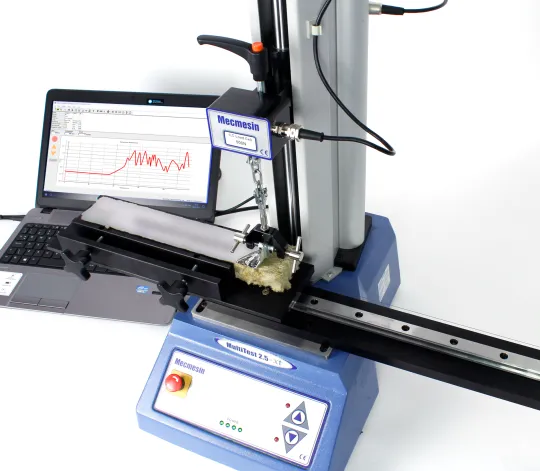

太阳能电池板剥离测试

Case study

氧化铝球体耐压试验

Case study

电池端子焊缝完整性拉伸试验

Case study