A Mecmesin fornece há muito tempo soluções de teste de força e torque a fornecedores e contratados do setor de energia. Fabricantes estabelecidos de tubos de petróleo, água e gás para todo o país e submarinos realizam testes de compressão e tração nos tubos como parte das verificações de CQ nos revestimentos. Conectores, válvulas e coletores são testados para garantir que sua resistência mecânica seja suficiente para condições adversas. Os conectores elétricos que utilizam terminais soldados ou soldados precisam ser testados quanto à sua resistência à tração.

À medida que a ênfase está se voltando cada vez mais para métodos novos e sustentáveis de gerar ou capturar energia, tem havido um desafio crescente em fornecer soluções de teste de controle de qualidade a preços acessíveis para os setores emergentes da indústria.

Energia solar

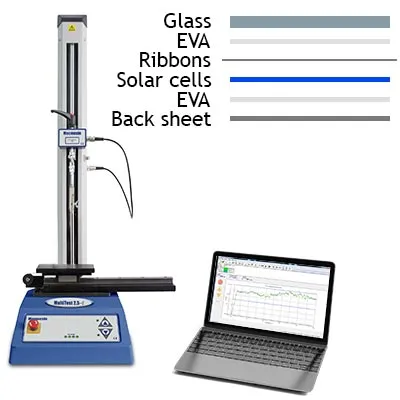

Um painel solar fotovoltaico (PV) é um sofisticado "sanduíche", composto de diferentes camadas de materiais avançados. Uma célula solar de filme fino (TF) é feita depositando finas camadas de filme fotovoltaico (por exemplo, Tedlar®) em um substrato, como vidro, plástico ou metal, e essas células são então montadas em painéis rígidos ou semi-flexíveis. O desempenho efetivo desses painéis solares fotovoltaicos depende de muitos fatores, incluindo sua capacidade de suportar danos mecânicos à medida que são expostos a extremos ambientais.

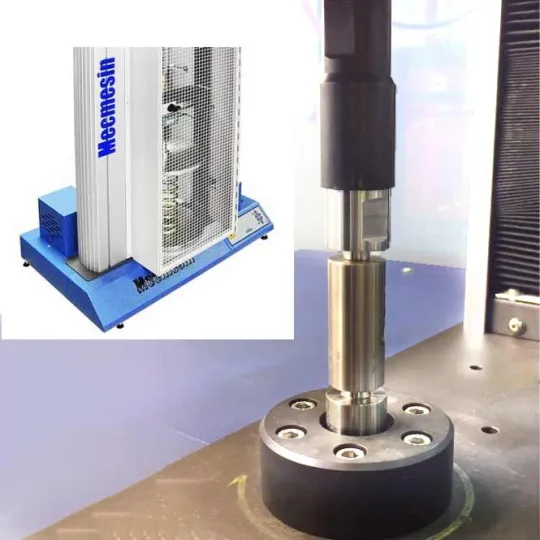

O teste de resistência mecânica é, portanto, uma parte crucial das verificações iniciais e contínuas do controle de qualidade para:

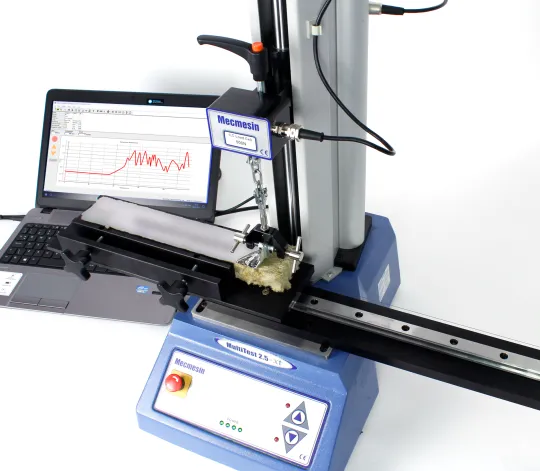

- Resistência à adesão na ligação inicial do EVA ao vidro, filme ou PET - método: teste de descascamento de 90 ° ou 180 °

- Retenção da resistência à adesão após exposição a temperaturas extremas de temperatura e umidade, como parte de ensaios de requalificação - método: teste de descascamento a 90 ° ou 180 °

- Resistência ao arrancamento dos conectores e cabos MC4 usados na caixa de junção fotovoltaica

- Força de montagem da estrutura do módulo fotovoltaico para garantir que possa suportar os requisitos de rolamentos de carga

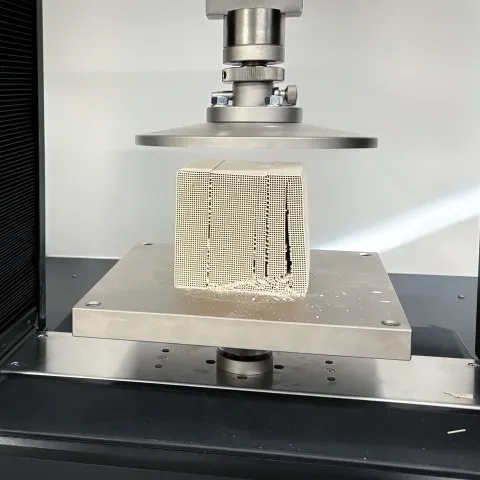

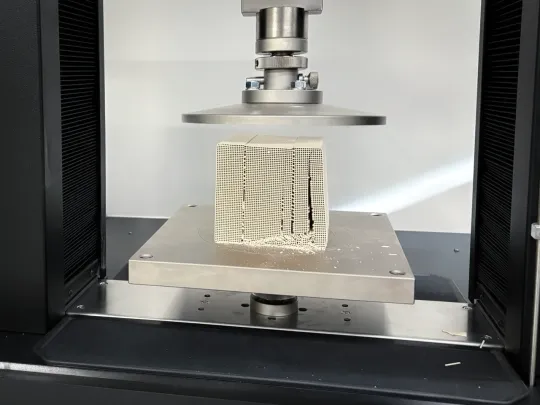

- Punção e resistência à flexão do vidro

Obtenha conformidade regulamentar, teste com uma variedade de padrões internacionais, por exemplo, ASTM, BS, DIN ou especificações internas.

Nossos equipamentos de teste de força, materiais e torque oferecem soluções práticas e versáteis para os seus requisitos de controle de qualidade a um preço atraente. Temos mais de 40 anos de experiência na solução de desafios de controle de qualidade no setor de energia.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section