金属是航空航天,汽车,电子和医疗等许多技术先进行业的核心,更不用说传统的建筑,能源和机械领域。金属产品,零部件和机械的生产商都面临着测试挑战,以确保它们达到规定的强度和性能等级。

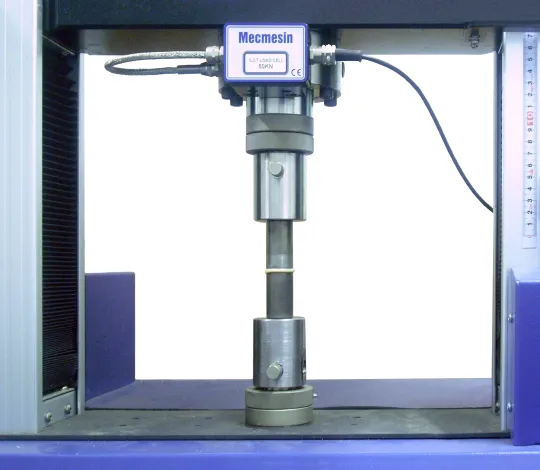

对于设计工程师和质控专业人员而言,了解金属在加工金属之前,过程和之后的特性至关重要。通过施加静态拉力,压缩力和剪切力来测试金属材料直至失效,是确定其特性的一种快速而实用的方法。

金属通常以各种形式生产,并且都使用经典的拉伸,剪切,压缩和弯曲的机械强度测试方法来符合各种ASTM,ISO,EN和行业标准:条带(热轧和冷轧)轧制),薄片和箔,棒材,电线和电缆,管道,铸件和锻件,紧固件。

Mecmesin 的力学,扭矩和材料测试系统可用于多种应用,包括:

- 拉伸强度:

- 金属铜棒

- 用于摩擦材料(例如制动器)的钢纤维

- 镀锌丝

- 钢和铝管

- 金属装配体

- 扣件

- 焊接接头

- 线束和线束

- 铝复合板(“登山鼓剥离测试”)

- 抗压强度:

- 轴向压制烧结金属制品

- 压实的金属粉末(“绿色强度密度测试”)

- 冲压件(“压出测试”)

- 不锈钢螺栓(“推出测试”)

- 管道

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Case study

金刚石磨边刀具的断裂强度

Case study

轨道车弹簧测试

Case study

工业固定装置和紧固件

Case study

雷管冲击管

Case study

测试金属百叶窗原材料的抗张强度

Case study

高性能等离子涂料

Case study