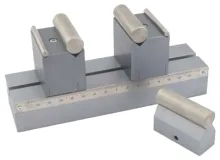

Bend jigs

Flexural load tests are popular since they closely characterise how a material or component may perform during its lifetime. As such they are often used to determine the mechanical properties of a whole range of materials including plastics, metals, wood, paper & board, ceramics.

‘Flexure bend’ tests usually draw upon loading at 3 or 4 points:

- 3-point bend test uses a jig which has 2 parallel ‘lower’ anvils to support the specimen. A single ‘upper’ anvil positioned exactly half-way between the 2 ‘lower’ anvils is used to apply compressive load to the specimen to determine its material characteristics. The 3-point test is used mainly for elastic and ductile materials.

- 4-point bend test differs in so far as there are 2 ‘upper’ anvils which apply compressive load to the specimen and are positioned symmetrically around the 2 ‘lower’ anvils. The 4-point test is used mainly for determining the properties of brittle materials.

In both 3-point and 4-point bend tests the ‘upper’ and ‘lower’ anvils can be fixed, rotating or tilting according to the requirements of the test standard. Rotating anvils help minimize the effects of friction by allowing longitudinal movement.

Tilting anvils ensure parallel contact with the specimen throughout the test.

Anvils can be radius-type or roller-type and may be held in a fixed position or be free to move. In addition the ‘lower’ anvils can be selected to make contact with the specimen at a single point or dual points.

The span of the anvils is set by manual positioning against a ruler-tape which indicates the span distance and using an allen key to secure. Alternatively support beams are available with leadscrews whereby anvil positions can be adjusted by using a hand-wheel.