Soluções de teste Mecmesin para produtos normalmente encontrados em casa.

Uma grande variedade de produtos, de pequenos aparelhos e ferramentas mecânicas a consumíveis e móveis, chega aos ambientes doméstico e de escritório. Eles estão sujeitos a uma vida inteira sendo empurrados, puxados e torcidos para que sua segurança, desempenho e durabilidade precisem ser testados.

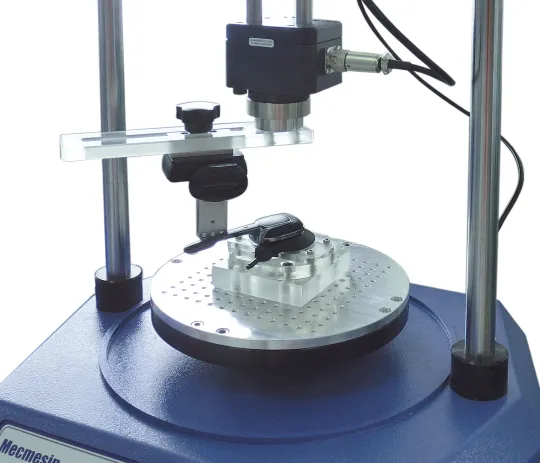

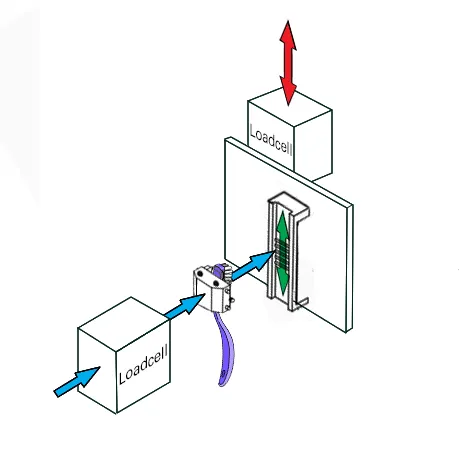

Os testadores de força e torque da Mecmesin estão idealmente posicionados para testes rotineiros de controle de qualidade ou por P&D para desenvolvimento e aprimoramento do projeto.

Teste de acordo com as normas internacionais ASTM, BS EN, ISO, DIN, CEN, OHSAS ou com seus próprios métodos de teste interno.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

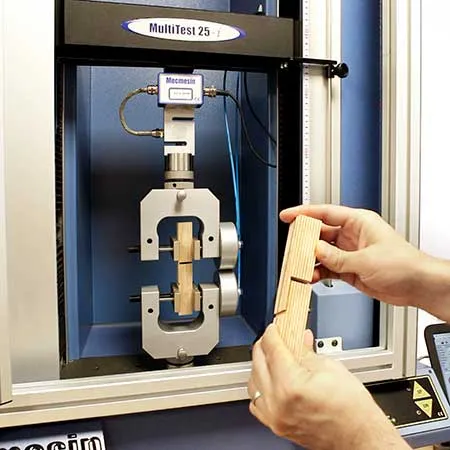

Teste de corte de madeira compensada

Peel testing identity cards

Page pull strength test

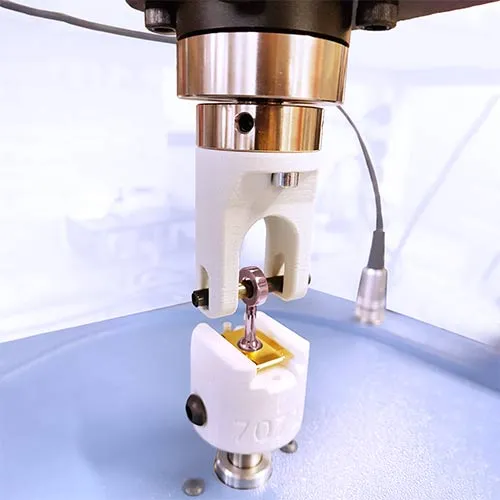

Teste TTF de pull-off do botão da roupa

![Casca de papel do cilindro [PDV13183] Casca de papel do cilindro [PDV13183]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1041-PDV13183-Filter-paper-peel.jpg.webp?itok=0sS3IdkX)