Segurança e confiabilidade são fundamentais na indústria aeroespacial. Em todo o mundo, muitas companhias aéreas, fabricantes de aeronaves e helicópteros comerciais e militares, fornecedores de fixadores, trens de pouso e aviônicos, além de empresas de manutenção, revisão e reparo, contam com equipamentos de teste Mecmesin para testar a qualidade, força, desempenho e segurança de seus materiais aeroespaciais, componentes e submontagens.

Nossos clientes aeroespaciais usam nossas soluções de teste para uma ampla gama de aplicativos de teste de controle de qualidade, incluindo:

- ensaios de compressão e tração de molas

- teste de cisalhamento e resistência à tração de elementos de fixação, por exemplo, parafusos, porcas e parafusos

- teste de torque de interruptores e controles rotativos usados em cockpits, sistemas de iluminação e de entretenimento a bordo

- testes de inserção / retirada por retirada de:

- terminais e juntas frisados

- fixadores

- testes de descascamento em compósitos usados em estruturas de aeronaves

- ensaios de resistência à tração e ao material de:

- ligações adesivas

- têxteis e tapetes para aeronaves

- cabos, mangueiras e tubulações

- juntas e O-rings

- material e cordas de paraquedas

- cintos

- juntas soldadas

- teares e chicotes de fiação

- avaliações de manuseio manual e tarefas de trabalho:

- manuseio de bagagem e carga

- controles de vôo operacionais

Obtenha conformidade regulamentar, teste com uma variedade de padrões internacionais, por exemplo, ASTM, BS, DIN ou especificações internas.

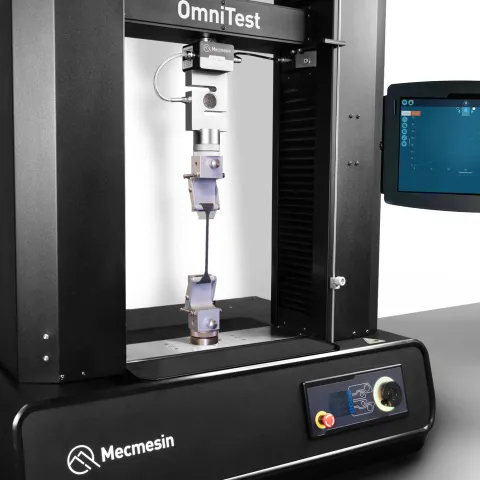

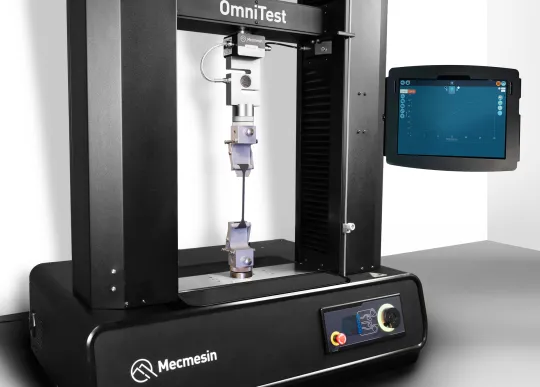

Nossos equipamentos de teste de força, materiais e torque oferecem soluções práticas e versáteis para os seus requisitos de controle de qualidade a um preço atraente. Temos mais de 40 anos de experiência na solução de desafios de controle de qualidade aeroespacial.

Temos também uma vasta experiência no setor mais geral da indústria de transportes .

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Teste de força solenóide

Teste de tração em juntas de borracha

Acessórios e fixadores industriais