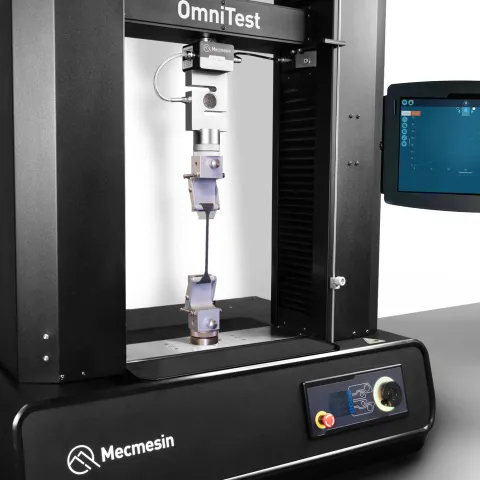

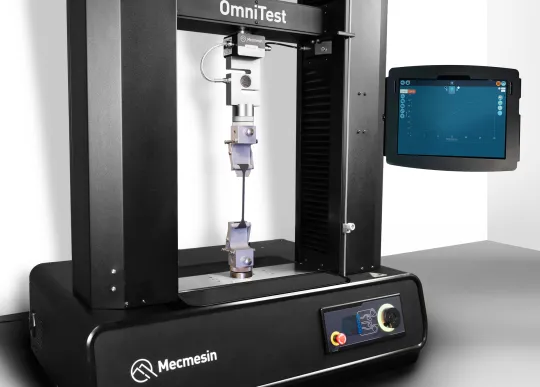

Safety and reliability are paramount in the aerospace industry. Around the world many airlines, manufacturers of commercial and military aircraft and helicopters, suppliers of fasteners, landing gear and avionics plus maintenance, overhaul and repair companies rely on Mecmesin test equipment to test the quality, strength, performance and safety of their aerospace materials, components and subassemblies.

Our aerospace customers use our test solutions for a wide range of quality control testing applications including:

- compression and tensile testing of springs

- shear and tensile strength testing of fasteners e.g. bolts, nuts and screws

- torque testing of rotary switches and controls used in cockpits, lighting and in-flight entertainment systems

- pull-off insertion/withdrawal testing of:

- crimped terminals and joints

- fasteners

- peel tests on composites used in airframes

- tensile and material strength testing of:

- adhesive bonds

- aircraft textiles and carpets

- cables, hoses and tubing

- gaskets and o-rings

- parachute material and cords

- seat belts

- welded joints

- wiring looms and harnesses

- manual handling and job task evaluations:

- baggage and cargo handling

- operating flight controls

Achieve regulatory compliance, test to a range of international standards, e.g. ASTM, BS, DIN or in-house specifications.

Our force, materials and torque test equipment offer you versatile, practical solutions to your quality control requirements at an attractive price. We have over 40 years experience in solving aerospace quality control challenges.

We also have a wealth of experience in the more general transport industry sector.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

Solenoid force testing

Aircraft brake unit spring testing

Tensile test on rubber gaskets

Industrial fixtures and fasteners