Mecmesin's solutions for the Jewellery & Watch industry.

Jewellery

Alloys and other materials used to manufacture jewellery must meet the needs of the production process. It must also give good service performance when worn by the customer.

Jewellery manufacturing balances the needs of being fit-for-purpose while keeping cost to a minimum, for example by reducing the precious metal in the piece.

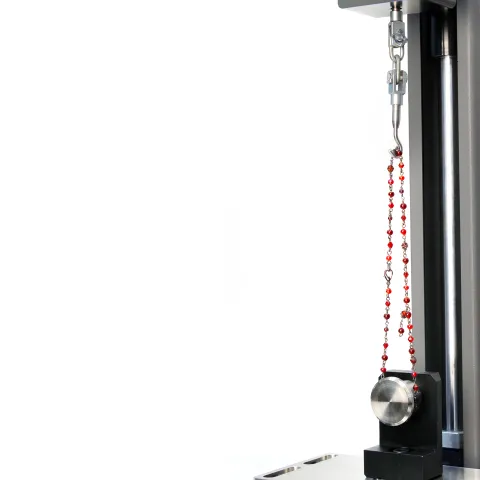

But can it take the stresses imposed when being worn? Will the springs in the clasps and catches work smoothly over time or will they fail prematurely? Will the links in a necklace break too easily? Is the claw setting in an engagement ring strong enough to retain the diamond?

To meet these demands it is necessary to perform quality-control checks, to ensure certain properties such as tensile strength and ductility fall within specified limits.

Watch

Wrist watches and timepieces are subject to many of the same physical strength requirements of jewellery but are characterised by their complexity and abundance of micro-mechanical parts.

From low-cost fashion item through to luxury timepieces, their performance depends on the perfect interaction of many components.

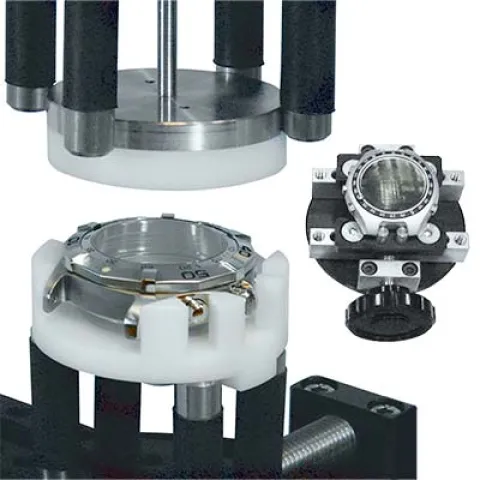

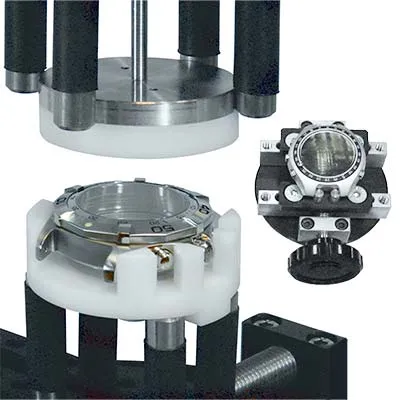

Testing the physical strength and performance characteristics of these parts, individually or as sub-assemblies, is a key quality-control requirement.

Common applications include measuring:

- friction torque on chronograph wheels, barrels and cannon pinions

- static torque of rivets

- push and pull-out strength of spring bar pins

- operational force of crowns, pins and clasps

- tensile strength and deformation of straps, bracelets, buckles and folding clasps

- torque characteristics of springs and rotating bezels

Improve quality and regulatory compliance

Achieve regulatory compliance, test to a range of international and industry standards, e.g. ASTM, BS, DIN or in-house specifications.

Our force, materials and torque testing equipment offer you versatile solutions to your quality control requirements at an attractive price.

We have over 40 years of experience in solving quality control challenges.

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section