Release Torque testing of Champagne and Sparkling Wine Corks

Solution

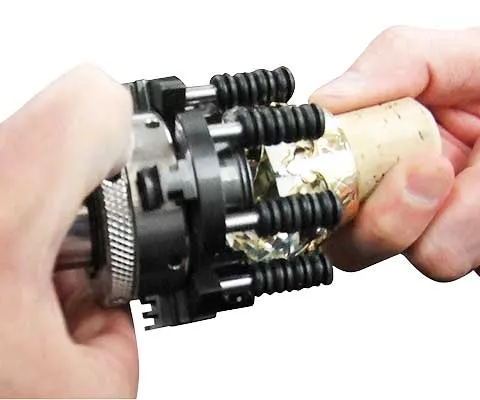

- Dedicated tester to twist and pull the cork in a helical motion

- Adjustable bottle clamping ability for a range of sizes

Benefits

- Complete system to meet the needs of closure manufacturer and beverage producer

- Confidence in consistent and repeatable testing for a complex removal operation

The Mecmesin CombiCork is a Quality tool that allows Korbel to test cork materials, ensuring they match with Korbel’s stringent quality standards. Testing removes subjectivity from the uncorking of champagne corks, troubleshooting our process or material variation, so our customers are able to have a consistent experience every time they open a bottle of the finest Korbel California Champagne.

Rick Marson, Technical Director

Korbel California Champagne

Requirement

Cork extraction strength from Champagne and sparkling wines is a critical quality-control parameter to measure. It is important to know in order to maintain a balance between easy opening of bottles by consumers, whilst retaining enough friction to avoid the cork exploding from the bottle and causing a nasty injury. Extraction strength has traditionally been determined by experienced operators but this is always a subjective assessment and open to variability between operators with results often being contested. When you wish to make multiple measurements, manual test methods can be too restrictive as operators performing multiple tests may become fatigued, increasing the risk of injury through improper handling of the sample.

There is currently no harmonised international test standard for measuring the release torque of sparkling wine corks but the need for improved quality-control and comparability by cork manufacturers/suppliers and their customers, has seen the development of objective testing methods which are becoming increasingly adopted within the wine industry.

Solution

Validation of the CombiCork test system was carried out by CIVC (Champagne Committee) France to correlate against results obtained using manual test methods by experienced operators. Criteria for conditioning the bottles before testing (eg. 48 hours in a chiller at 10°C, capping depth, liquid height) were established and an extensive number of samples were tested to measure the opening torque. The conclusion was that the CombiCork tester had excellent correlation and allowed for more reliable, objective measurement thus helping create a grading scale of < 1.2 N.m being classed as dangerous through to > 3 N.m being impossible to open.

The CombiCork Extraction Tester has since been adopted across various regions specialising in the production of sparkling wines with notable companies such as Korbel, GH Mumm and Diam.

Key features:

- Cork extraction test with repeatable pull and twist motion

- Suitable for a range of bottle sizes and cork diameters

- Special grips to clamp bottle and cork

Testimonial, cork manufacturer

The Combi Cork Extraction Tester helped us to simplify measurements because it is easy to set up. This system provides consistent reproducible and safe measurements, without any risk of injury to the operator. Therefore, we can establish valuable opening torque specifications, which are currently used for quality control measurements and development of new products.

Dominique Rabiot

R&D manager, Oeneo Bouchage, manufacturer of corks, France

Test equipment

The CombiCork Extraction Tester includes:

- Motorised test system with protective enclosure

- Rotary torque sensor

- Digital Torque Indicator with data-output function

- Mechanical or Pneumatic Grips for clamping corks and bottles