Extreme sports waterproof bio-textile mechanical properties

Solution

- Software-controlled tensile tester

- 250 N and 2.5 kN loadcells

- Vice grips and filament grips, for textile specimens

Benefits

- In-house testing with associated cost savings for the large number of samples

- Capability to perform tests to several standards using one system

Amphibio has been using the Mecmesin Multitest 2.5i to assess the mechanical properties of single fibres, yarns and textiles made of various materials for their suitability in the sportswear and performance textiles market. We needed equipment that would be able to provide us with repeatable and reliable results whilst being easy to use. By using this equipment, we have been able to make key decisions going forward in our material development by determining yarns and fibres with the most suitable mechanical properties. The grips recommended to us as well as the software interface make testing efficient and easy, allowing us to obtain rapid results. Overall, we are extremely happy with the service offered by Mecmesin, particularly because they were able to accommodate our needs during difficult COVID times and were also able to offer us our desired equipment rental agreement period which fit with our budget.

Deana Tsang, Design Engineer

Amphibio Ltd

Requirement

Amphibio Ltd develops bio-inspired materials technology for the outdoor and extreme sports industry. Its super-hydrophobic porous membrane textile can be used as an artificial gill to dramatically reduce the weight of diving equipment tanks and as an innovative and sustainable material for high-performance waterproof sportswear. The company places high emphasis on a circular philosophy, driving the engineering challenge of optimal function and waste elimination.

Amphibio wanted to quantify the strength and mechanical properties of various single fibres, multifilament yarns, woven and knitted textiles and fabrics. A range of international test standards are being used to ensure the highest quality of product:

- ASTM D3822: Standard Test Method for Tensile Properties of Single Textile Fibers

- ASTM D3217: Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

- ISO 2062: Textiles. Yarns from packages. Determination of single-end breaking force and elongation at break using constant rate of extension (CRE) tester

- ISO 13934-1: Textiles. Tensile properties of fabrics. Determination of maximum force and elongation at maximum force using the strip method

These test methods involve a large minimum number of specimens, some requiring at least 50, therefore a solution combining ease of use with repeatability and reliability was essential.

Solution

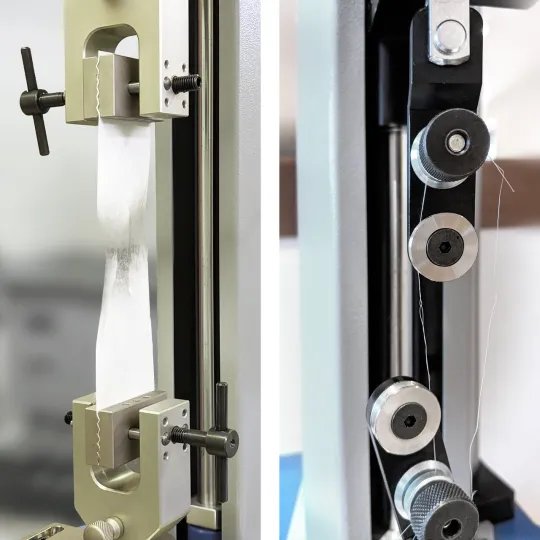

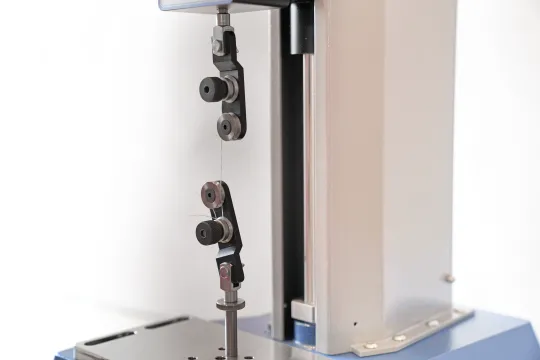

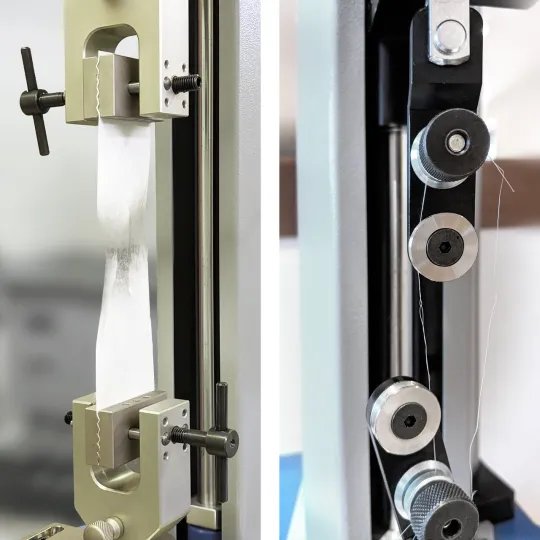

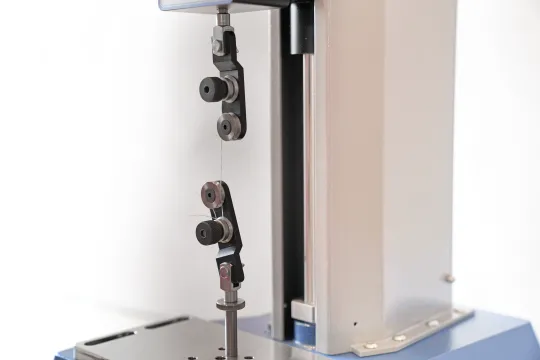

Mecmesin supplied a MultiTest 2.5-i software-controlled tensile tester with two capacities of loadcell to match the expected maximum loads. Two types of standard grips were also recommended; vice grips, designed for clamping the full width of fabric strip-test specimens and filament grips for yarns and fibres.

The test standards stipulate several conditions that the Mecmesin test system easily meets. The motor-driven crosshead enables the required constant rate of extension (CRE) of 100 % per minute, based on the gauge length, with enough test space to accommodate the sample extension. The grips’ clamping mechanisms also prevent slipping or cutting of the specimens and breaks at the jaws.

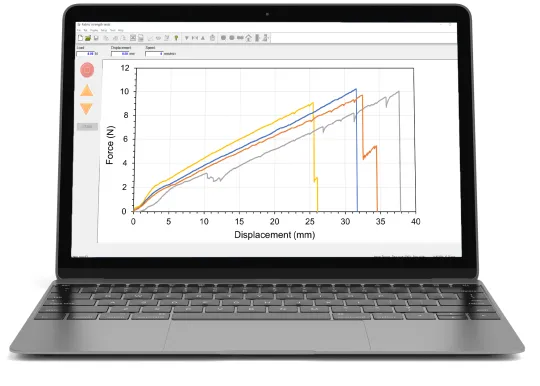

Under software control, the force applied and specimen elongation are accurately measured, shown graphically in real-time, and the necessary calculations are immediately performed. The breaking force at rupture and the elongation length at break are the fundamental results required, with the pass/fail criterion being a minimum desired peak force value. The software enables further values of interest to be calculated, such as strength (force per unit area at failure) and specific strength, or tenacity (strength divided by density). Secure data handling allows sample identification, e.g., lot number, to be associated with the testing and export to systems for further analysis.

In being able to perform these tests themselves, the design engineers at Amphibio have not only made cost savings by avoiding external testing facilities but have gained the ability to more fully control their own tests in developing these ground-breaking, innovative apparel materials.

Test equipment

- MultiTest 2.5-i computer-controlled test stand and software

- 250 N and 2.5 kN loadcells

- Single-action Vice Grip, Filament grips