Jaws

Choosing the most appropriate jaw type for a tensile grip can be tricky. It is a balance between having sufficient hold of the specimen to prevent it slipping and not having too ‘aggressive’ a hold which damages the specimen.

Below is a simple guide with tips on jaw selection to assist you:

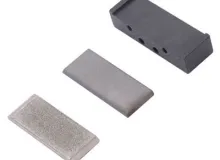

- blank jaws

For smooth surfaced materials. Allows user to machine or affix own surface (eg emery paper) - pyramid or diamond jaws

For materials which need a “bite” to secure a good grip (eg soft metals {aluminium, copper, soft steel, paper, and board) - rubber jaws

For fragile samples, which may get weakened by pinching at the contact-edge of the grip. (e.g. thin films, filaments, fibres, and thin aluminium) - V jaws

For round samples where flat jaws do not provide enough surface contact (eg wires, rods, tubes) - wave jaws

For slippy materials which need more surface contact to secure a good grip (eg textiles, fabrics, and tissues)

Specialised jaws

- line-contact jaws

For thin materials, requiring a point contact to determine the true gauge length of the specimen between the grips (eg rubber, textiles, or paper). These jaws have a radiused contact face and are supplied with the equivalent rubber coated flat-faced jaw for the opposing jaw surface. Only to be used where specified in international standards. Available for several side-action grips, please contact Mecmesin with your requirements.