Search results

Mecmesin systems and gauges are designed for the application of international and industry standards for quality and safety.

Force and torque testing within the construction industry primarily concerns the integrity and resilience of materials, the methods of joining and fastening and their strength, and safety throughout.

- compressive strength of young sprayed concrete (shotcrete) and grouts

- compressive strength of block materials

- bending resistance and flexibility of beams or panels

- shear and compressive strength of building materials and joined surfaces

- pull-out force of fasteners and fixings

- tensile strength of cables

- compliance testing of health and safety appliances

It also involves verifying the settings of tools and mechanisms used in construction to check they are applying the desired force and torque limits.

Mecmesin systems and gauges are designed to allow you to test for quality and safety in accordance with international and industry standards. When combined with our Emperor force and torque control and analysis software, there is complete flexibility for accurate and repeatable testing.

Test to ASTM, BS EN, ISO, DIN, CEN

Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

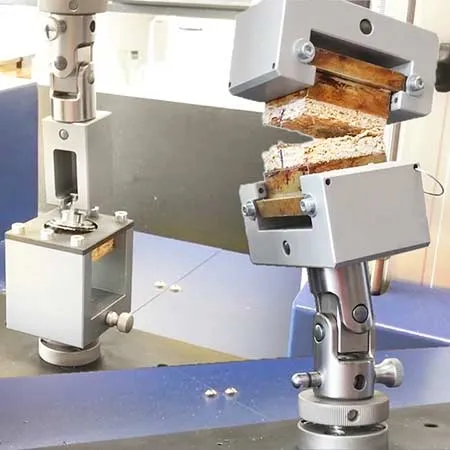

Lap shear testing of plywood

Mineral wool insulation panel testing

Wire rope termination crimp safety

Industrial fixtures and fasteners

Detonator shock tubing

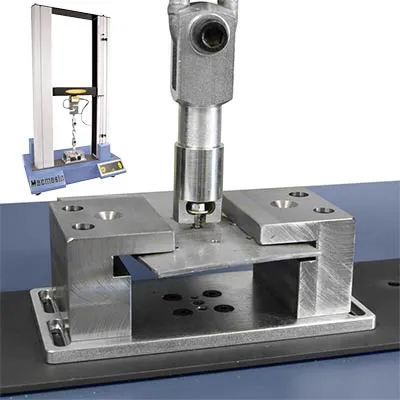

Screw retention force of building materials

Scaffold support netting tester