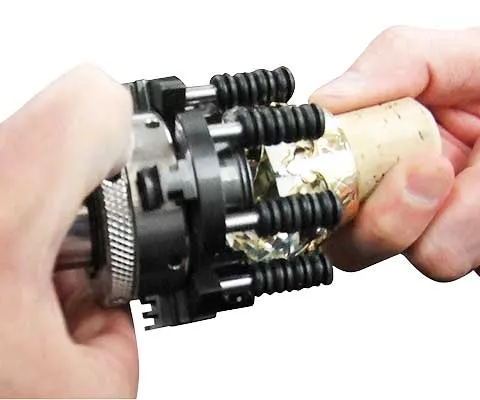

The CombiCork-dV is a purpose-built tester to reliably and objectively measure the release torque when extracting a cork from a sparkling wine bottle. The closure is extracted with a representative helical motion; combining twist and pull.

Its innovative bottle clamping design makes it quick and easy to carry out batch testing of champagne corks fitted to bottles ranging in size from 25cl to Magnum.

The CombiCork-i is a purpose-built tester to reliably and objectively measure the both the pull-out force and release torque when extracting a cork from a still wine or spirit bottle. The closure is extracted with a representative helical motion; combining twist and pull.

Its innovative bottle clamping design makes it quick and easy to carry out batch testing of capsulated 'bar-top' design corks and stoppers fitted to bottles in a wide range of sizes.

The CombiCork is a purpose-built tester to reliably and objectively measure the release torque (and optionally the pull-out force) when extracting a cork from a sparkling wine or spirits bottle.

Its innovative bottle clamping design makes it quick and easy to carry out batch testing of champagne or capsulated (‘bar-top’) corks fitted to bottles ranging in size from 25cl to Magnum.

Got a question about a product? Your local representative is...

Mecmesin/PPT Group, UK

Accessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesOverview

The CombiCork extraction tester is used across the world by both cork manufacturers and producers of sparkling wines and spirits. It allows them to reliably check the suitability of different cork materials and designs, including the effects of any coatings and additives, for the openability of the bottle.

Traditional methods have relied upon corks being manually extracted by an operator with a subjective assessment of how difficult it was to do so. By using a tester which accurately replicates the helical extraction motion, objectively measures, indicates and reliably records the relevant release effort, this subjectivity is removed.

In the case of sparkling beverages, objectivity helps to resolve conflicts between the cork suppliers and the cork users over the relative difficulties in extraction. It is particularly important to avoid identifying an insufficiently low torque as a good indicator of a cork, which could then inadvertently explode out of the pressurised bottle and cause harm to the consumer.

The CombiCork creates the controlled test conditions to deliver a measurement repeatability which is difficult to achieve through subjective manual test methods.

At a glance

- Replication of helical twist and pull motion

- Clear, immediate display of relevant effort; torque, force

- Pneumatic clamping for efficient and quick testing

- Accommodates a wide range of standard bottles

- Repeatable, quantified, calibrated results

- Perform CIVC-recommended testing (for Champagne)

CIVC is the Comité Interprofessionnel du vin de Champagne

Product datasheets

Product Brochures

Features and benefits

Functionality for sparkling wines

The CombiCork-dV provides a helical motion to simultaneously pull and rotate the cork from the bottle at a constant pre-set speed; the Champagne and sparkling wine industry's standard of 60 rpm and 900 mm/min. The relevant opening effort of peak torque is displayed in N.m.

Sparkling wine bottles are held in place by a set of 4 interchangeable rubber-faced jaws. These are clamped against the bottle via a pneumatic chuck; the preferred option as it provides faster operation and is ergonomically easier to use for the operator. A manually-operated vice can be specified.

Using simple controls the bottle is then raised to a pre-set stop where the cork can be inserted into the upper grip. The wire cage (muzzle) is then cut to release it before testing. The bottle is then lowered by the tester at a fixed speed whilst the release torque of the cork is captured on the display unit.

A stainless steel drip tray catches any liquid spillages whilst a safety guard protects the operator from any risk of splintering glass.

Functionality for still wines and spirits

The CombiCork-i tester is expanded to extraction test capsulated corks, including ‘bar-top’ and ‘Altop’ varieties; universally used as spirit bottle closures. As spirits do not generate the internal pressure of a sparkling beverage, the stopper is not forced outwards by the pressure. This means that the extraction force to pull out the cork (measured in daN) is of equal relevance as the release torque (in N.m).

The CombiCork-i is equipped with a load sensor and software package which monitors both extraction force and release torque. Cyclic testing can also be performed—extracting and re-inserting the closure repeatedly—simulating real-world usage. This allows manufacturers of capsulated corks and producers of spirits to monitor the true performance of these stoppers and control their quality accordingly.

Find out more

To learn more about the CombiCork extraction tester and to discuss more detailed information about its suitability for your application, contact our Sales Engineers at Mecmesin.

Key applications

Got a question about a product? Your local representative is...