Some of our customers

Featured case studies

Standards

Featured or equivalent test standards for Mecmesin solutions in this section

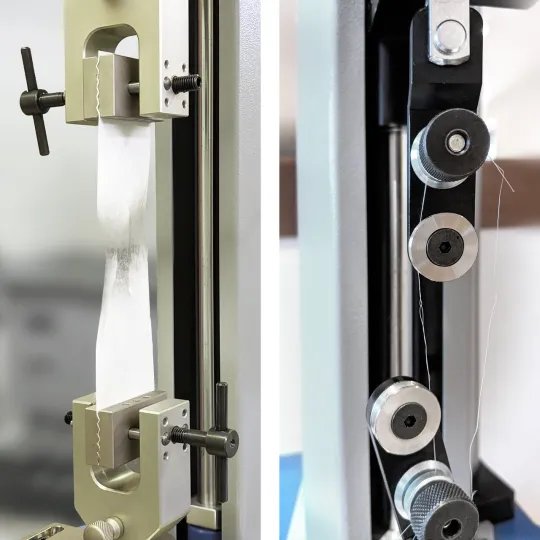

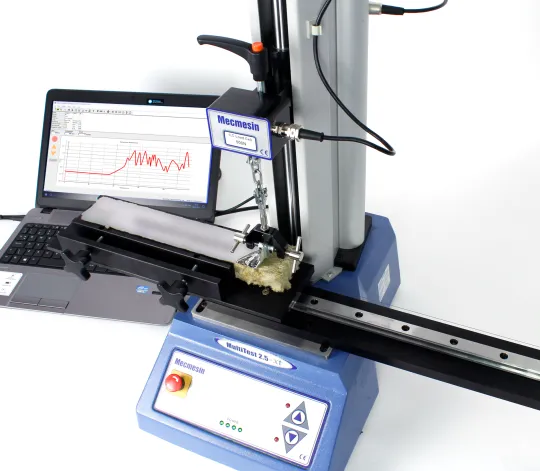

Fishing line and knot strength

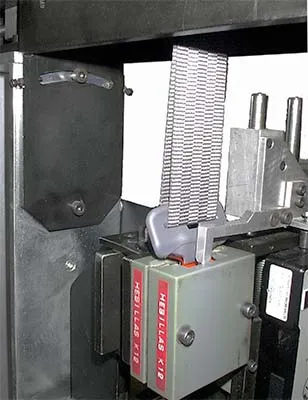

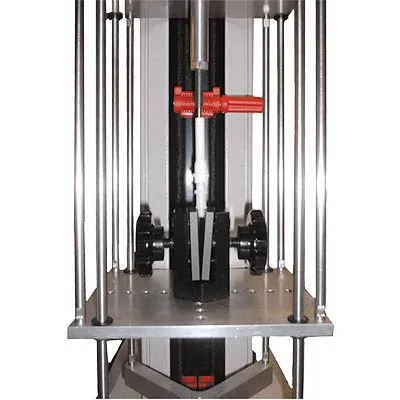

Tensile testing wire joining systems

การทดสอบแรงโซลินอยด์

การทดสอบความแข็งแรงของหน้ากากใบหน้า

การทดสอบความต้านทานแรงดึงของถุงมือยาง

บังคับใช้เจ้าหน้าที่ตำรวจและชุดป้องกัน

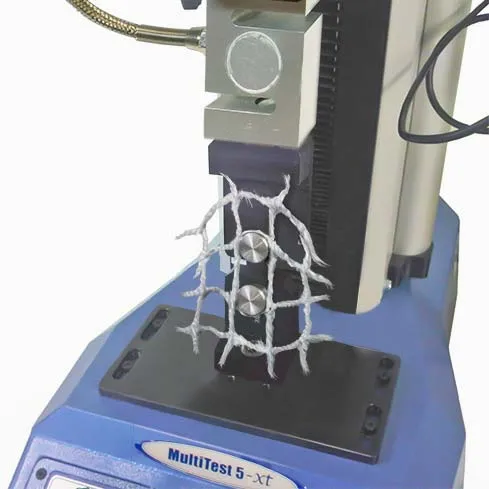

การทดสอบความต้านทานแรงดึงของอวนเป็น ISO1806

การทดสอบแผงฉนวนขนแร่

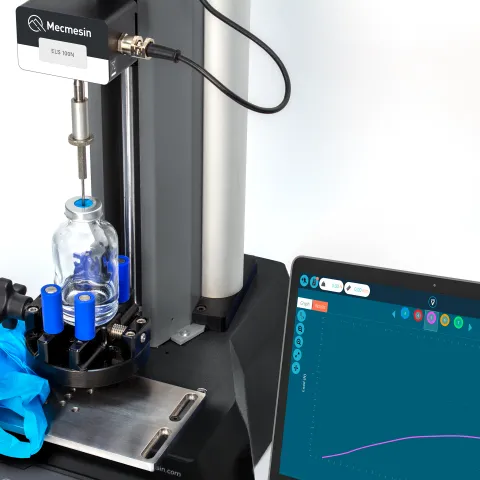

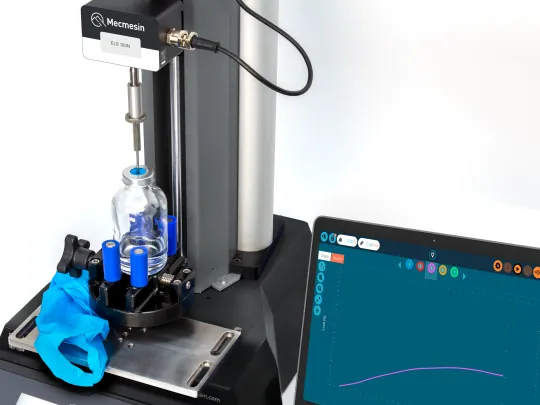

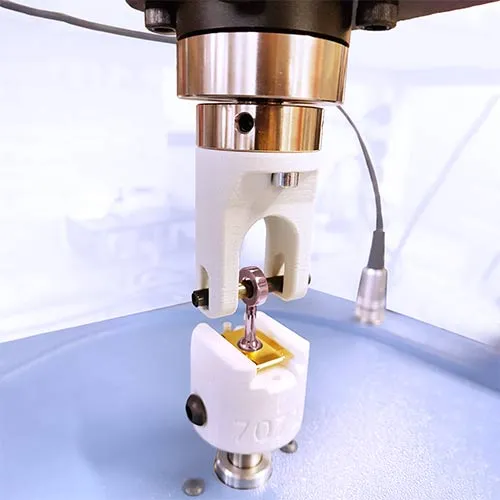

หลอดฉีดยาแก้ว Luer ล็อคสิ่งที่แนบมาดึงออก

ความแข็งแรงของส่วนประกอบไฟฟ้า

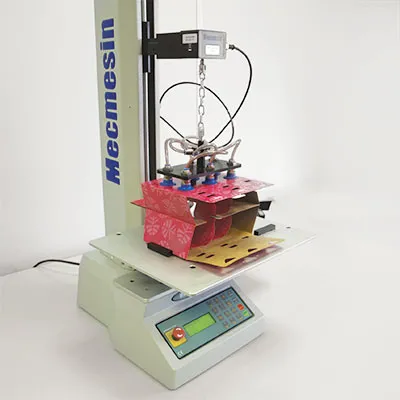

ที่ใส่ขวดเครื่องดื่มกระดาษแข็งแฉ

การทดสอบการดึงท่อหลอดฉีดยา

การทดสอบการดึงตัวกรองทางเดินหายใจแบบอินไลน์

ความสมบูรณ์ของการประกอบแม่พิมพ์ฉีด

การทดสอบความแข็งแรงของสายเคเบิลอย่างคุ้มค่า

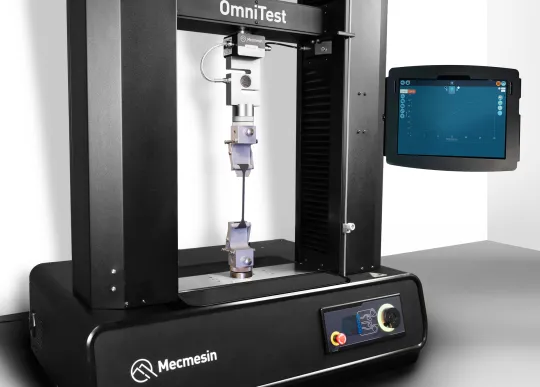

การทดสอบการดึงแปรงเครื่องสำอาง

การทดสอบอุปกรณ์ล็อคเข็มขัดนิรภัย

การทดสอบเครื่องช่วยฝึกหัวฉีดปากกา

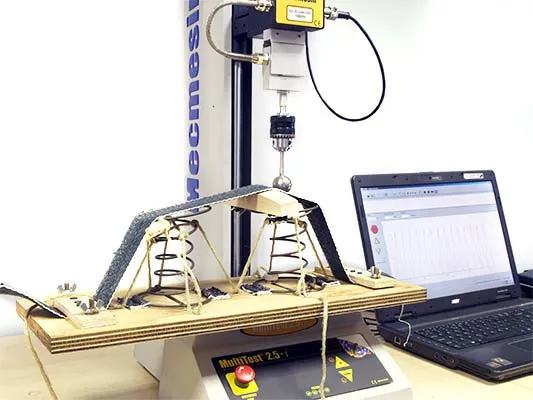

การทดสอบสปริงอุปกรณ์ทางเดินหายใจ

การทดสอบความตึงของฟิล์มพลาสติก

การทดสอบแรงดึงของขั้วแบตเตอรี่

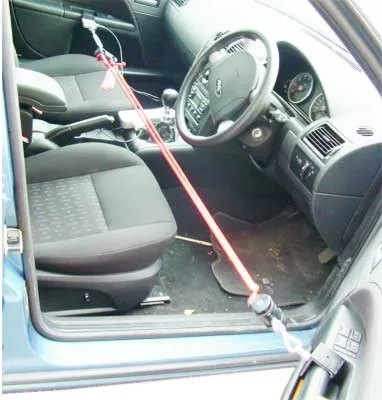

ความพยายามในการปิดประตูรถ

การทดสอบแรงดึงของฟิล์มโพลีเอทิลีน

การทดสอบแรงดึงบนปะเก็นยาง

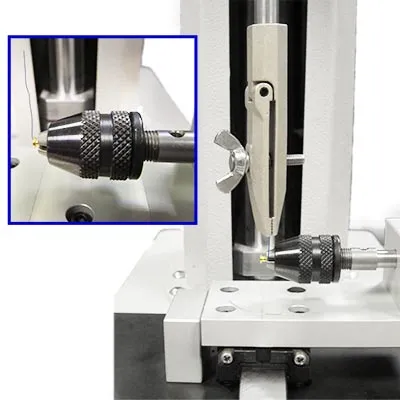

การทดสอบความแข็งแรงของเส้นบอกแนวทางการแพทย์

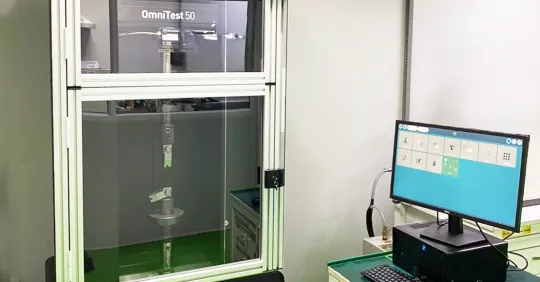

การทดสอบอุปกรณ์ทางการแพทย์

ความสมบูรณ์ของบรรจุภัณฑ์กระดาษแข็งติดกาว

การทดสอบการรับรองความปลอดภัยในการก่อสร้าง

Solenoid testing

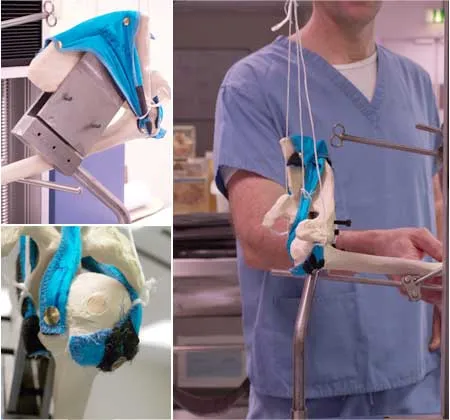

การทดสอบแรงดึงของข้อไหล่เทียม

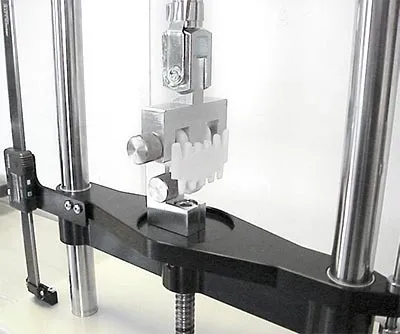

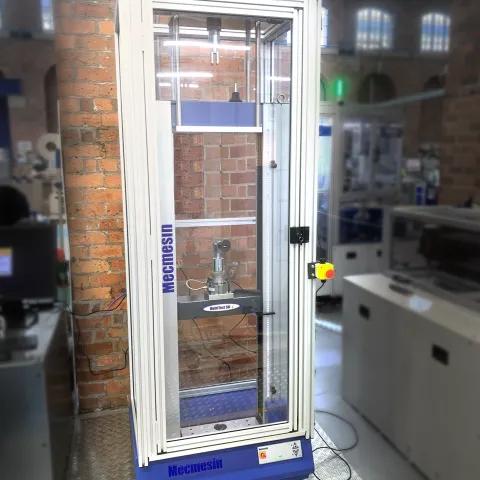

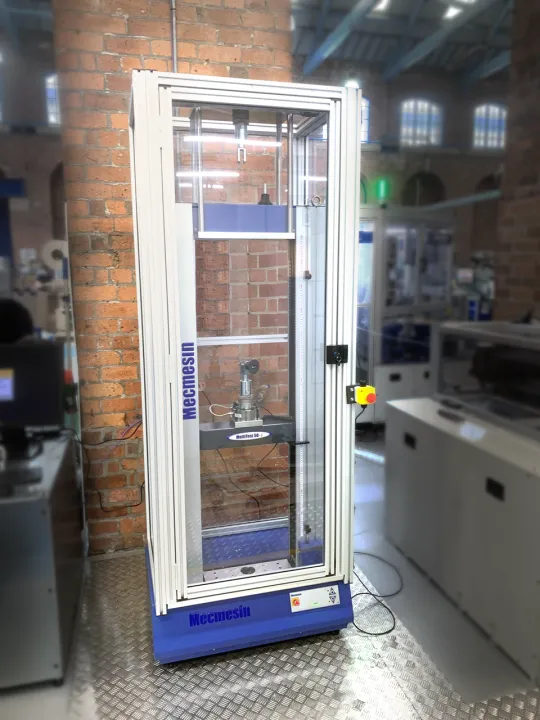

Scaffold support netting tester

Safety critical welds in vehicle airbags

การทดสอบการดึงเข็มกับปลอกโลหะ

การออกแบบและผลิตสปริง

![ความแข็งแรงในการดึงออกของเข็มฉีดยา luer [PDV10032] ความแข็งแรงในการดึงออกของเข็มฉีดยา luer [PDV10032]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1717-PDV10032-web.jpg.webp?itok=AcqJb3d0)

![การทดสอบการพับกล่องดูดติดตั้งตำแหน่งเปิดเต็มที่ [PDV8017] การทดสอบการพับกล่องดูดติดตั้งตำแหน่งเปิดเต็มที่ [PDV8017]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/989-cardboard-beverage-tension-test-system.jpg.webp?itok=EFU9vHec)

![การดึงท่อแพทย์ [PDV14004] การดึงท่อแพทย์ [PDV14004]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1669-PDV14004-med-tube-pull-web.jpg.webp?itok=roDJsAsL)

![สายเคเบิ้ลแคม [PDV12086] สำหรับการทดสอบแรงดึงของลวดเชื่อมที่ประกบกัน สายเคเบิ้ลแคม [PDV12086] สำหรับการทดสอบแรงดึงของลวดเชื่อมที่ประกบกัน](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2020-12/1702-PDV12086-web.jpg.webp?itok=jiggOPnQ)

![แปรงเครื่องสำอางดึงออก [PDV14098] แปรงเครื่องสำอางดึงออก [PDV14098]](/sites/default/files/styles/case_study_gallery_540w/public/case-study/2024-11/Cosmetics-brush-tuft-pull-out-1556-PDV14098-OmniTest.png.webp?itok=MGK0_x1-)