The MultiTest-i is a versatile tensile and compression tester controlled by Emperor software running on a PC.

The single-column range fits neatly on your bench-top and is ideal for product testing applications according to your own test methods.

A wide range of tensile grips, bend jigs and compression fixtures make the single-column MultiTest-i easy to use for measuring tension and compression, from as little as 2 N right up to 5 kN.

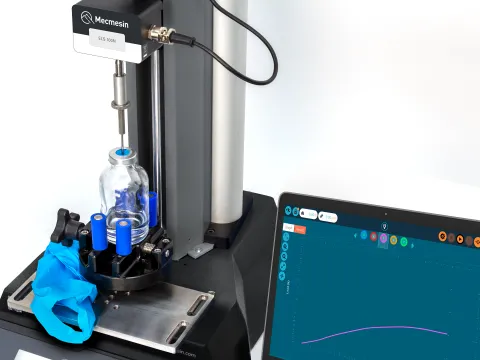

The MultiTest-xt is a versatile tensile and compression tester controlled by Emperor software running on a touchscreen console.

The single-column range fits neatly on your bench-top and is ideal for product testing applications according to your own test methods.

A wide range of tensile grips, bend jigs and compression fixtures make the single-column MultiTest-xt easy to use for measuring tension and compression from as little as 2 N right up to 5 kN.

The MultiTest-i is a versatile tensile and compression tester controlled by Emperor software running on a PC.

The single-column range fits neatly on your bench-top and is ideal for product testing applications according to your own test methods.

A wide range of tensile grips, bend jigs and compression fixtures make the MultiTest-i easy to use for measuring tension and compression, from as little as 2 N right up to 5 kN.

Looking for the right testing solution?

MultiTest test frame

A ballscrew-driven motorised test frame designed to apply tension and compression from

Its versatile construction makes it perfectly suited for testing all kinds of components in a quality control or R&D environment.

Test frame

The single-column MultiTest-i and MultiTest-xt feature a ballscrew-driven motorised test frame, which is designed to apply tensile and compressive forces from 2N right up to 5 kN.

A dovetailed crosshead design ensures operators can quickly and easily attach new ILC loadcells, that are automatically recognised by the software.

The base plate of the MultiTest is pre-drilled with threaded holes to directly accept a wide range of grips and fixtures.

Its versatile construction means that the frame has enough daylight to accommodate tall specimens and enough travel to measure the tensile strength of the most elastic of materials.

Connect your computer

The MultiTest-i requires a Windows PC to run the Emperor software and control the tensile tester. Its compact design and small footprint make it the perfect selection as a bench-top device.

Integrated console

The MultiTest-xt is fitted with a Windows-based touch screen console. Comparable to a standard PC but operates excellently as a standalone tensile tester. It saves time by not having to move to and fro a computer.

Force sensors

The ILC range of interchangeable loadcells are specially adapted for the MultiTest-i and -xt test systems. Plug and play for automatic calibration and a range of capacities for all requirements, from 2 N to 50 kN.

ILC Loadcells

The ILC range of interchangeable tension and compression loadcells is specially adapted to the MultiTest-i and -xt test systems.

They plug into the frame and their calibration characteristics are immediately recognised by the software of the tester without any input from the operator.

Each loadcell is fitted with a threaded hole or stud for connection to a range of grips to hold your specimens.

To ensure that you have the optimum selection to meet all your tension and compression testing needs, eighteen different loadcells are available. All loadcells measure from zero and cover the range from 2 N right up to 50 kN.

Loadcell capacity, range and accuracy

Each loadcell reads from zero to its full nominal capacity (listed below). Measurement accuracy is an outstanding ±0.1% or ±0.25% of the loadcell capacity.

Each sensor is delivered as standard with its own calibration certificate traceable to national standards.

Servicing and calibration

Mecmesin also provides annual servicing and torque sensor re-calibration. Talk to one of our engineers or your local national distributor to find out more.

ILC (2 - 500N)

Features a loadcell in a housing with a dovetailed fitting to mount on the crosshead of a single- or twin-column test stand.

Compact design saves space and maximises available daylight.

ILC-S (100 N - 5 kN)

Features an S-beam loadcell beneath a housing with a dovetailed fitting to mount on the crosshead of a single- or twin-column test stand.

The S-shape allows a greater contact surface with grips to provide enhanced stability.

ILC-T (10 - 25 kN)

Features an S-beam loadcell beneath a housing with a through-hole to bolt onto the crosshead of a twin-column test stand.

The S-shape allows a greater contact surface with grips to provide enhanced stability.

ILC-P (20 - 50 kN)

Features a Pancake loadcell beneath a housing with a through-hole to bolt onto the crosshead of a twin-column test stand.

The Pancake design suits higher loads and provides greater overload protection particularly against extraneous loads.

Emperor™ Software

Emperor™ Force software

Easy-to-use software with almost limitless freedom to design and customise tension and compression tests to suit your needs. Developed by Mecmesin in close collaboration with our customers, Emperor™ is now trusted by over 5,000 companies for the detailed testing and evaluation of their products.

Create simple tests for the production line and more complex laboratory tests to prove design standards are met.

Key features

Create

Intuitive user interface

Build test routines step by step

Favourite one-touch tests

Test

Real-time graph plotting

Display measured and calculated values

Clear pass/fail indication

Report

Standard and customisable templates

Print results to Adobe PDF format

Export results to Excel and SPC packages

Trusted by over 5,000 customers worldwide

Learn more about EmperorAccessories

Choosing your accessories

It's important that your sample is gripped and held correctly to achieve accurate test results.

Our accessory catalogue contains a wide range of accessories and you should find exactly what you need. Key specifications (such as load rating) are listed on all of our grips and fixtures.

Example test accessoriesOverview

The MultiTest-i tensile and compression tester is controlled by software run on a computer. It delivers both consistency and reliability by controlling the key test parameters of force, displacement and speed.

This means that the inherent variability found when using manual test methods is almost fully removed. It is relied on by quality-control professionals around the world to objectively assess the mechanical strength of their components, assemblies and finished products.

The single-column MultiTest-i testers are the perfect solution for measuring forces up to 5 kN (1100 lbf) on a huge variety of components made from almost any material, either during their normal operation or when being pulled/pushed until they deliberately fail or break.

Their compact design ensures they occupy very little space on the bench-top and their intuitive controls make them easy to use, even for novice operators.

The versatile construction of these single-column tensile testers means that you can test high-elongation specimens on the long travel 0.5kN and 1kN models, making them ideal for tensile and adhesive peel tests on plastics and rubbers. Alternatively, you can take advantage of our popular 2.5 kN and 5 kN models for general purpose testing of smaller specimens to determine their tension, compression, flexure, shear and fracture characteristics.

Whichever tester you choose you can be sure that Mecmesin will deliver you an affordable solution that does not break your budget. That's why customers from industries as diverse as automotive, aerospace, cosmetics, electronics, packaging, pharmaceutical & medical, have all come to rely on Mecmesin as their partner of choice when it comes to tensile and compression testing.

The single-column MultiTest-i testing system comprises four key elements:

Test frame

The single-column MultiTest-i and MultiTest-xt feature a ballscrew-driven motorised test frame, which is designed to apply tensile and compressive forces from a few mN right up to a capacity of 5 kN. Its high-quality construction, manufactured under ISO 9001 quality standards, ensures the ultimate in repeatable testing.

When seeking to precisely measure forces across a wide range it is often necessary to use multiple loadcells. The dovetailed crosshead design of the MultiTest ensures the operator minimises set-up time by quickly and easily sliding on a new loadcell, which is automatically recognised by the software.

The base plate of the MultiTest-i and MultiTest-xt is pre-drilled with threaded holes to directly accept a wide range of grips and fixtures. It also accepts the quick-change (QC) adaptors which speed up the interchange of grips when you need to perform a variety of different tests.

Its versatile construction means that the test frame has enough daylight to accommodate tall specimens and enough travel to measure the tensile strength of the most elastic of materials.

Make use of your own PC to run its software and take advantage of its small footprint to make it the ideal choice as your bench-top tensile & compression tester.

Loadcells

The ILC range of interchangeable loadcells is specially adapted to the MultiTest-i and MultiTest-xt. They plug into the frame and their calibration characteristics are immediately recognised by the tester without any input from the operator.

Fourteen different sensors, all measuring from zero, are available to cover the range from

Each ILC sensor is delivered as standard with its own calibration certificate traceable to national standards.

Software

Emperor software is at the heart of the MultiTest-i and MultiTest-xt test systems. It runs on any Windows computer and controls the motor of the test frame whilst collecting data at an impressive 1,000 Hz from the ILC loadcell and displacement encoder of the frame.

Step-by-step test routines can be quickly and easily created according to the exact requirements of your testing procedures. The most commonly used test routines can then be simply selected by the operator using their 'favourites' button or from a standard drop-down list.

By plotting measurement data in real-time on a graph the operator can identify exactly how the test specimen is performing. Preset calculations are used to analyse the data to determine whether the specimen has met the pass/fail criteria of the quality-control specifications.

At the end of the test, the powerful reporting module within Emperor™ allows the operator to issue a test report as a PDF. Additionally, the data can be exported to Excel or to the network for further analysis by a Statistical Process Control (SPC) package.

Grips & fixtures

Holding your test specimen in place without it slipping is essential to obtaining repeatable results. Mecmesin has designed a range of tension and compression grips to hold a variety of components. They include wedge grips, vice grips, peel jigs, bend jigs, compression plates and many more...

The varying nature of specimen sizes and shapes often makes it necessary to design and produce a special grip. Mecmesin's team of design engineers can work with you to develop the best grip for your specimen and utilise our 3D printers to produce lightweight, precision fixtures to meet your needs.

Product datasheets

Product Brochures

Key specs

Tension & Compression

Test frame rated capacity

| Model | 0.5 kN | 1 kN | 2.5 kN | 5 kN |

|---|---|---|---|---|

| N | 500 | 1000 | 2500 | 5000 |

| kgf | 50 | 100 | 250 | 500 |

| lbf | 110 | 220 | 550 | 1100 |

Dimensions

Headroom (vertical space to fit sample)

1205 mm (47") - 0.5kN model

1005 mm (39") - 1kN model

526 mm (21") - 2.5kN model

590 mm (23") - 5kN model

Throat depth (column to centre-line of loadcell)

67 mm (2.6") - 0.5, 1 & 2.5kN models

95 mm (3.7") - 5kN model

Height

1616 mm (64") - 0.5kN model

1416 mm (56") - 1kN model

941 mm (37") - 2.5kN model

1082 mm (43") - 5kN model

Width

290 mm (11.4") - 0.5, 1 & 2.5kN models

328 mm (12.9") - 5kN model

Depth

414 mm (16.3") - 0.5, 1 & 2.5kN models

526 mm (20.7") - 5kN model

Weight

31 kg (68 lbs ) - 0.5kN model

27.5 kg (61 lbs) - 1kN model

24 kg (53 lbs) - 2.5kN model

38 kg (84 lbs) - 5kN model

Excluding console, approx. 2.5 kg (5.5 lbs)

Speed

Range

1 - 1000 mm/min (0.04 - 40"/min) - 0.5, 1 & 2.5kN models

1 - 500 mm/min (0.04 - 20"/min) - 5kN model

Accuracy

±0.2% of indicated speed or ±20 µ/min, whichever is greater*

* See help.mecmesin.com for additional info.

Resolution

1 mm/min (0.04"/min)

Displacement

Maximum crosshead travel (between limit switches)

1186 mm (47") - 0.5kN model

986 mm (39") - 1kN model

507 mm (20") - 2.5kN model

590 mm (23") - 5kN model

Accuracy

±0.13mm per 300mm

(±0.005" per 11.8" travel)

Resolution

0.01mm (0.0004")

Load

Accuracy

±0.1% or ±0.2% of full scale depending on loadcell selected

Resolution

1:6500

Units of measurement

mN, daN, N, kN, gf, kgf, ozf, lbf

Sampling rate

2000 Hz

Data-acquisition rate

1000 Hz, 500 Hz, 100 Hz, 50 Hz, 10 Hz (user selectable)

Common specifications

Voltage

230 V AC 50 Hz or 110 V AC 60 hz

Operating temperature

10 - 35°C (50 - 95°F)

Humidity range

Normal industry and laboratory conditions, non-condensing

Communications

Digital I/O

6 input, 6 output (TTL)

Output of test results to PC/printer/datalogger (MultiTest-xt)

Yes - Includes auto-export to Microsoft Excel. Also data-export via RS232 port (direct or via USB/Network converter in ASCII format)

Network communications (MultiTest-xt)

Ethernet RJ45, USB for external wireless connectivity

Key applications