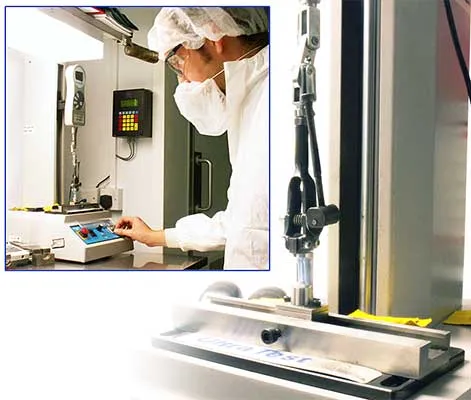

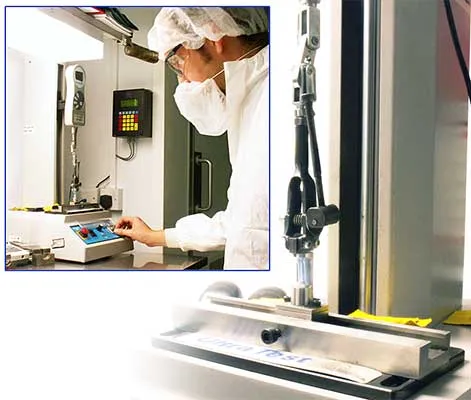

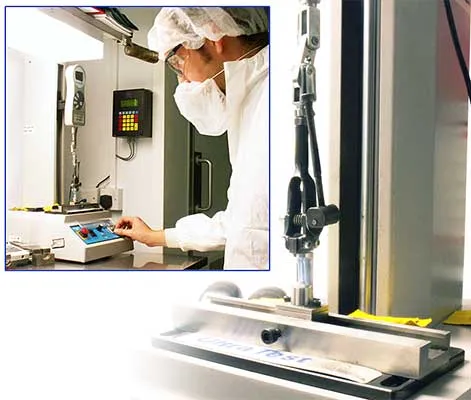

Lancet needle retention test

Solution

- Motor-driven tensile tester

- Needle lancet assembly supporting fixture

Benefits

- Quick results displayed immediately

- Optimum repeatbility with motor-drive

- Efficient QC testing at point of production

"We have been using Mecmesin equipment to perform retention tests on our range of lancet needles for over 8 years. We find the system easy to use for regular in-process checks, and generally reliable with prompt servicing from Mecmesin when required."

John Potter, Quality Systems Engineer

Owen Mumford

Requirement

A UK based medical device company who design and manufacture a range of blood glucose monitoring and control equipment used by healthcare professionals and consumers across the globe, needed a test solution to ensure the quality of their lancet needles. The company manufacture a variety of single use lancets, used by diabetes sufferers to obtain capillary blood samples when mounted into a lancing device.

The lancet comprises a steel needle moulded into a plastic base with a twist-off cap covering the point. To ensure the needle is not dislodged from its base when the cap is removed prior to use, stringent in-house production specifications dictate the minimum acceptable retention force of the needle within the plastic surround.

Solution

The company use a Mecmesin AFG 500 force gauge on an UltraTest stand (now superseded by the MultiTest 1) to perform retention tests on the lancet needles at regular 6-hourly intervals. This guarantees consistent manufacturing quality. The plastic base is placed under a custom-engineered mounting block, with the needle tip exposed vertically.

A lever-operated pin vice is fitted to the tip and a tensile load applied to the needle at a rate of 200 mm/min until it is dislodged from the plastic base. This durable Mecmesin system has been in constant use at the point of production for over 8 years.

Test equipment

- AFG 500 Force Gauge

UltraTest Stand (now superseded by the MultiTest 1-dV)

Lever-Operated Pin Vice

Custom-engineered mounting block (lower fixture)